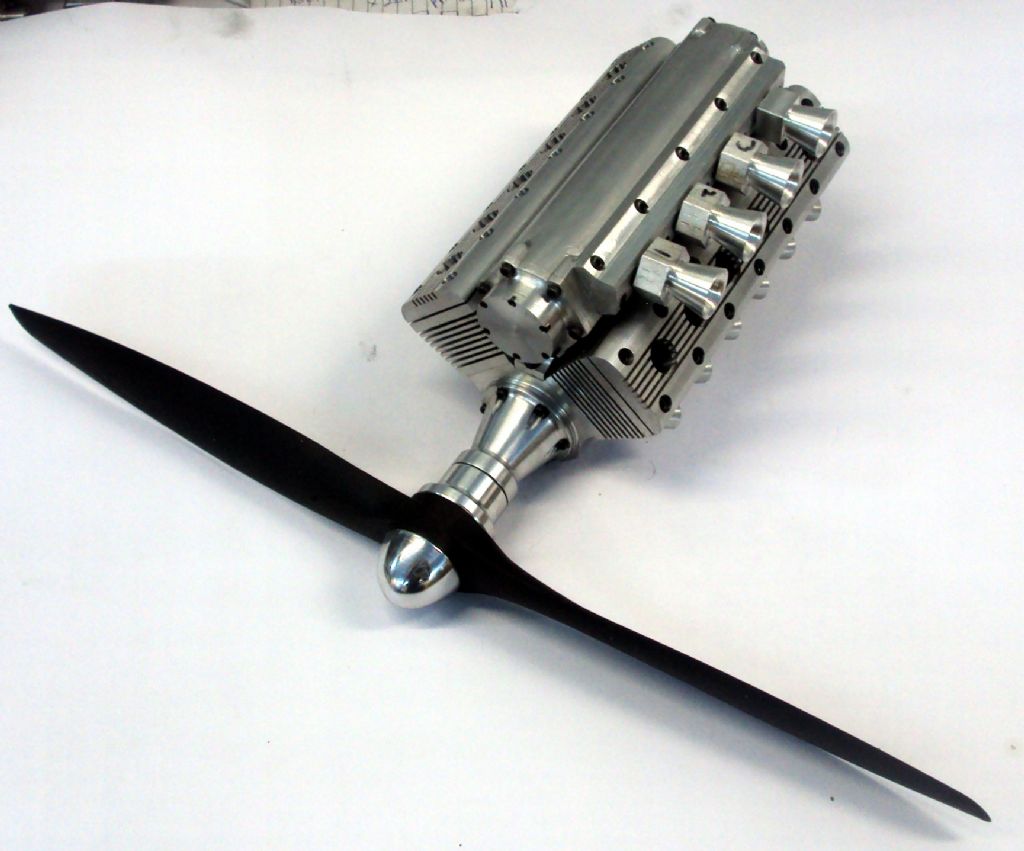

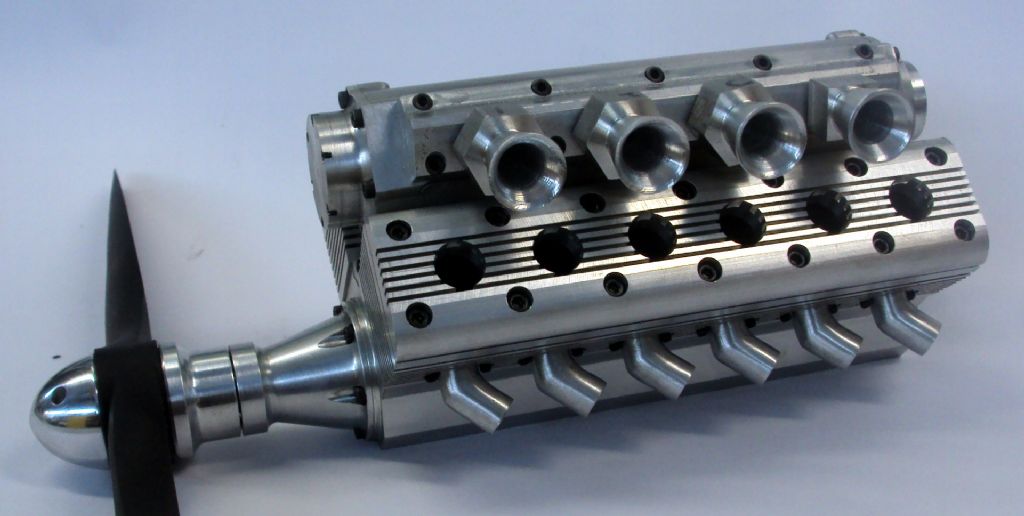

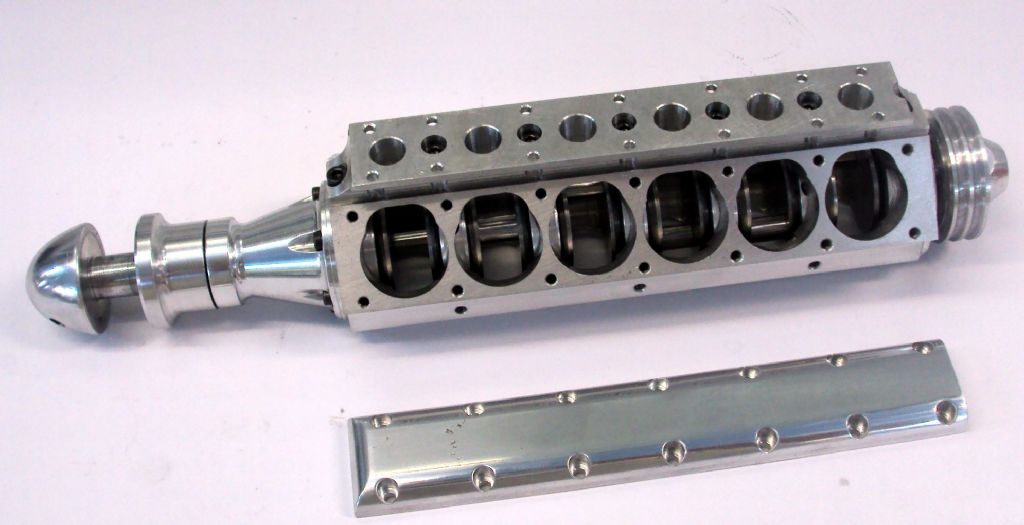

supercharged V12 2 stroke

supercharged V12 2 stroke

- This topic has 274 replies, 55 voices, and was last updated 4 May 2025 at 08:10 by

Michael Gilligan.

Michael Gilligan.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Meddings MF4 Manual

- Speed camera

- IME Watchmakers lathe

- Motor won’t start

- Request for a Slot to be Milled in a Shaft

- Bearing boxes for ball race

- J&S grinder – belt which way ?

- Twin Engineering’s heavy mill/drill quill removal

- The Stevenson Trophy – Entries Invited

- The Bradford Cup – Nominations Wanted