You are correct there Bernard, not everyone is  …….

…….

As I recall I made my first silencer for an IC engine sometime in the early seventies. It was for an OS-40 glow motor fitted in my first model boat. The engine was not a water cooled version but the standard unsilenced R/C motor, the manifold made from brass with a brass collector silver soldered to it leading via silicone tubing to an expansion chamber in the rear of the boat. Well over-engineered in respect to the engine but the only materials available to me at that time. It was much to my surprise that the first run showed that the silver solder had melted with the heat, clearly evidenced by the way the solder had run.

What's this to do with JB Weld you may ask.

Well, a few years later and well before any use of JBW in an ME application I made another silencer from aluminium for a similar engine – an OS Max 35S. This was for use in a control line model. At an early competition the central bolt that held all three components of the chamber came loose in flight and the silencer left the aircraft – an immediate loss of all points due to the jettison rule. One of the other competitors came over to me after and said something like "JB Weld will cure that" I queried what it was and once told doubted that an epoxy would stand the heat involved. However, well before the use of any computer, I finally found a supplier and bought some.

Still with a high degree of scepticism the silencer was reassembled with JBW but still retaining it's central bolt. I was expecting to witness burnt residue around the joints but no, nothing even after many flights. I decided to remove the bolt to see what happens – nothing – it just carried on being a silencer the whole thing held together with nothing more than the JBW. This was my first realisation of just how strong this stuff was in high temp conditions. (Anyone who has used glow engines know just how hot they get).

Simplistic? Well maybe but the proof was in the pudding. I have made quite a few silencers since using nothing but JBW. Flown considerably I have had only one failure where the single 8BA cap head bolt holding the silencer itself to the manifold sheared.

On first use I grabbed the first thing at hand to mix it on, a piece of flat steel plate, the residue curing in a solid lump. Quite sometime later I looked for a similar piece of steel and thought I could quickly chisel the JBW off. How wrong that assumption proved to be as it was extremely hard and resistant. I gave up and looked for another piece of material,l the JB coated piece still lurking in the workshop somewhere as a good example.

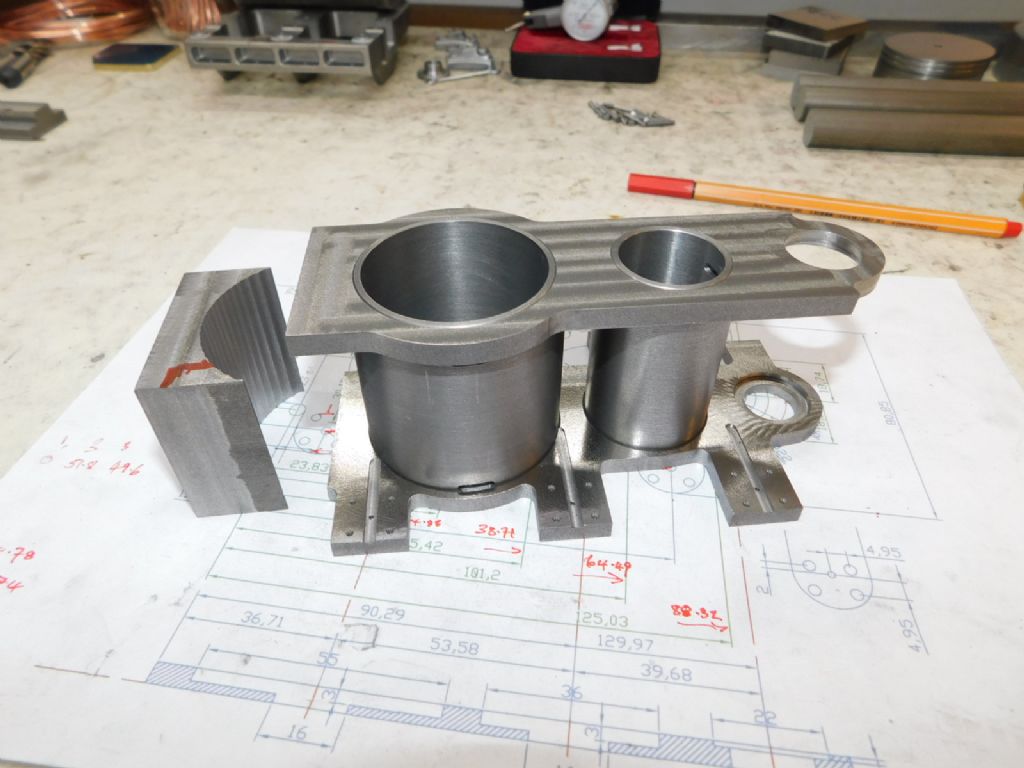

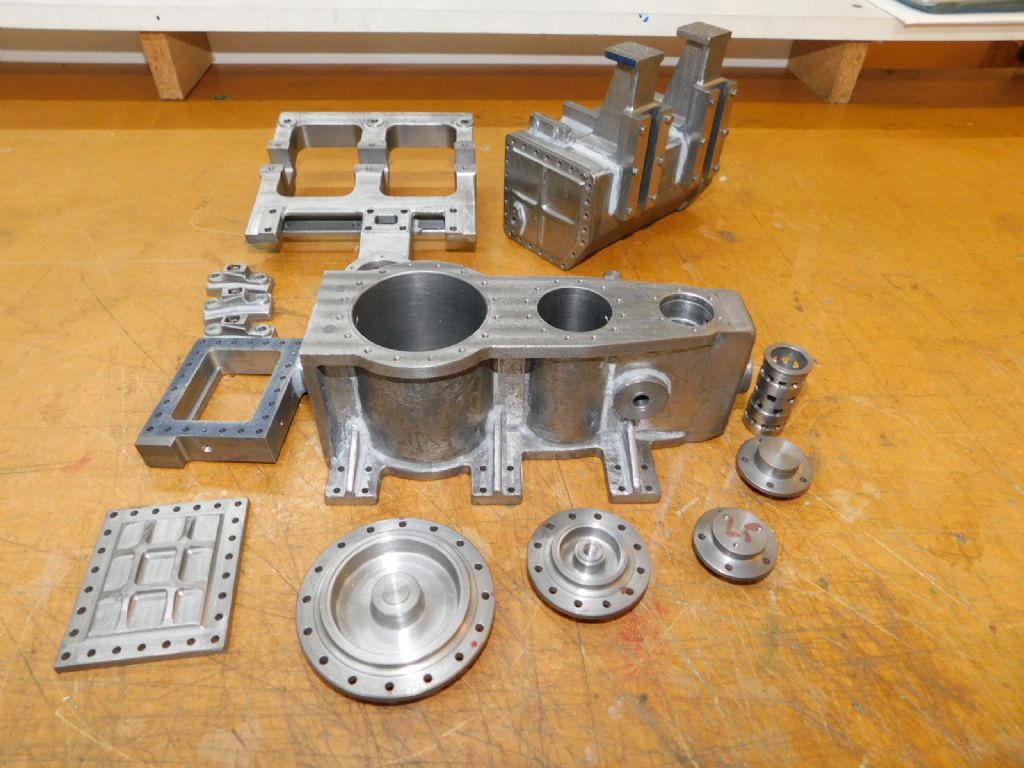

It was this prior use and the discovery of just how hard it was that lead me to the conclusion that it would make for a good bonding agent to fabricate 'castings' – the Waller engine, much much later, finally being the first real use in this application.

As readers can no doubt surmise – I am a convinced advocate of the product based on a high degree of success with its attributes. Yes there are other products available but none, as far as I am aware, match them like for like at the reasonable cost that JBW is available for.

This product has been the subject of other threads before – a quick search of JB Weld will soon find them

Best -Tug

Ian Skeldon 2.