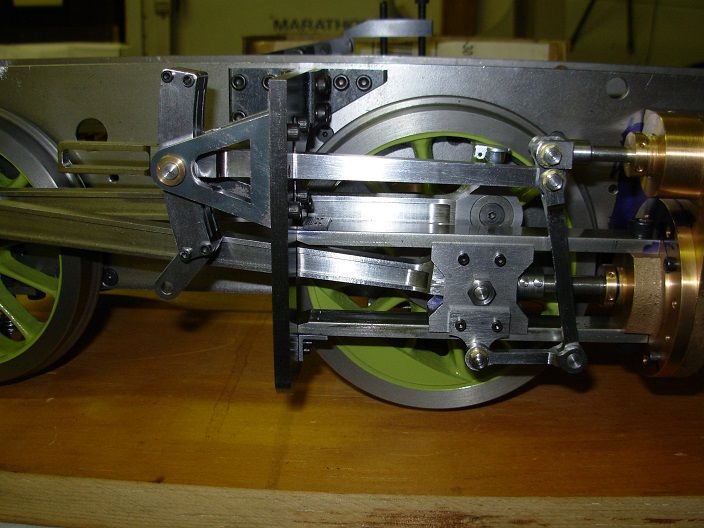

For folks building a Super Simplex, I just wanted to give you a heads up if you are going to use the motion plate from Model Engineers Laser. The "window" in the motion plate that the cross head guide bars fit into, is positioned 1/16" too high. Also, the dimension from the top of the plate to the center of the window is not correct as shown in the ME article. It should be 2-5/8" as shown on a current version of the drawing. The plate can be used, if positioned 1/16" below the top edge of the frame.

Of course, the plate will no longer support the running board but, a 1/16" spacer can be put under the running board in this area.

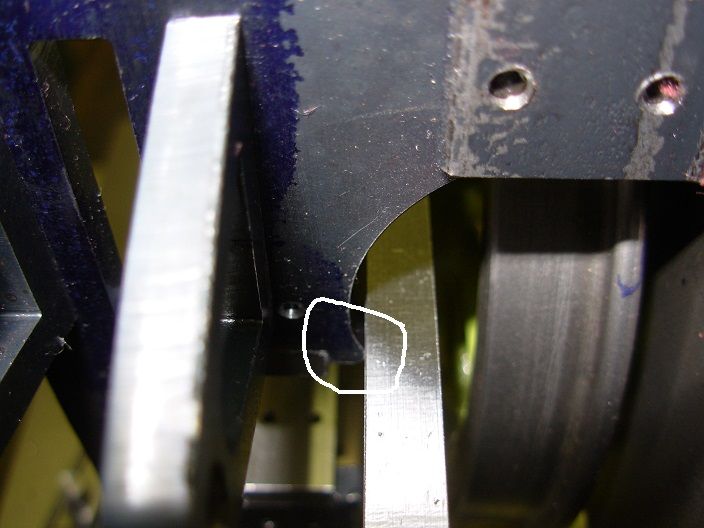

Also, there is a radius that was added to the edge of the window that is not shown in any version of the motion plate drawings. This radius will foul the connecting rod when the leading wheels move all the way to the left or right.

The wheels in the photo have been moved all the way to the left. The circled area shows the radius on the motion plate touching the con rod.

This can be put right by machining the inside of the window straight down, as shown on the drawings.

Hope this helps out a few folks attempting this build. In general, the laser cut parts are a real time saver and I would recommend them for anyone building a locomotive. Just make sure the parts match the drawing, and that the drawing is correct!

David

p.s. For Julian, I have reduced the inside diameter of the cylinders. John Baguley has a wonderful web site including some downloadable spread sheets to help design locomotives. Yes, the cylinders are a bit large for the boiler. I have reduced them to 1-3/8" inside diameter. This is more in proportion to the grate and boiler size.

John Kinnane.