Thanks Ramon,

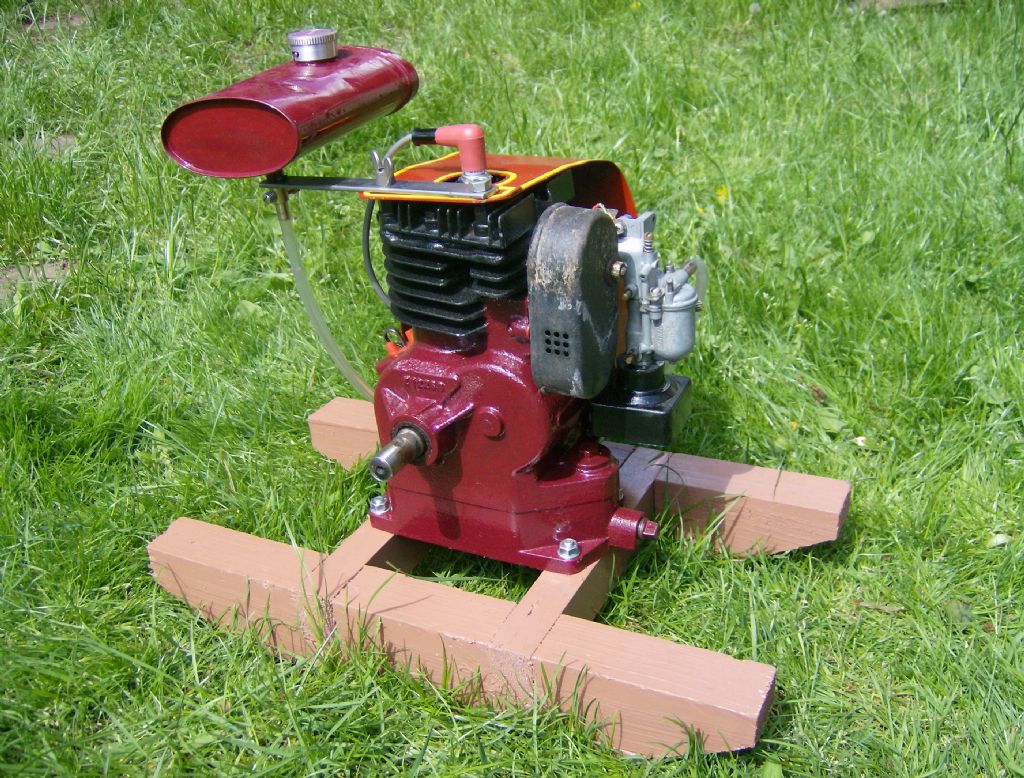

The ancient engine is making me guilty as I embark on this one… although I have done some really nice work on the eccentric straps and rods (if I say so myself). Thinning them down from 1/8" thick was a challenge until I realised I could use the very tip of a huge clamp to hold them on the mill table.

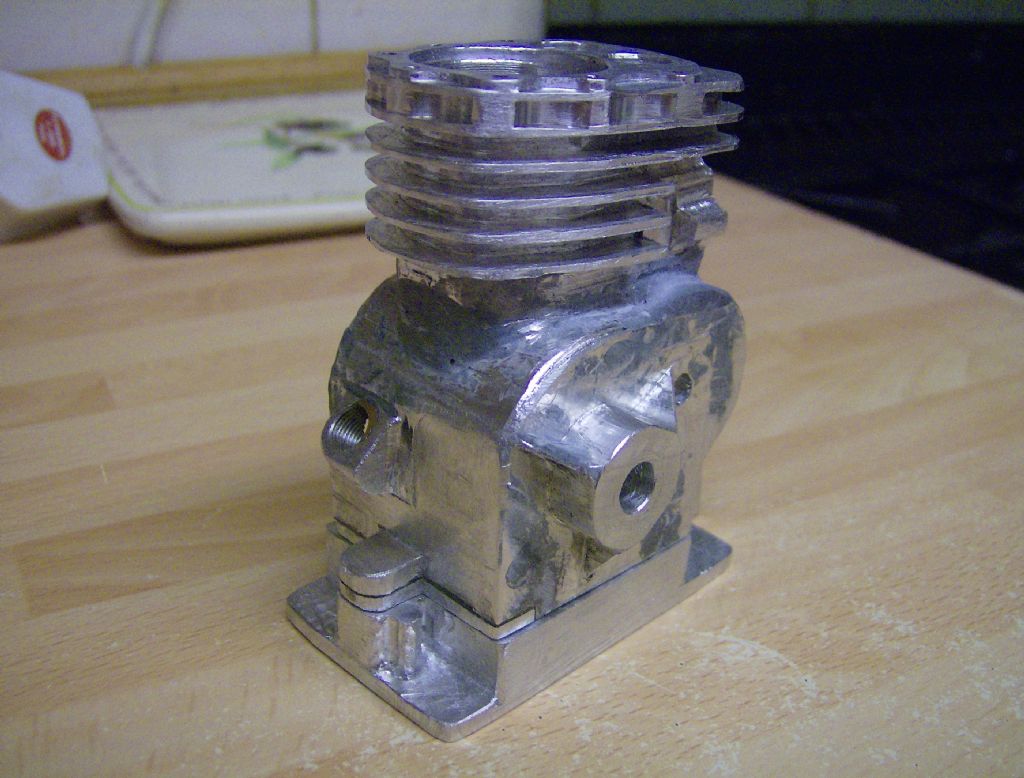

This engine has been planned for ages and I set the target or making the crankcase over the break. It still needs a littl;e more shaping – reducing fin ends, the hole between the manifold attachments, some fixing holes and tapping.

I slightly bent the base with over-enthusiastic clamping. I spent ages rocking it on the 'surface plate' and tweaking it without success. Eventually I applied some engineer's blue that showed two small high spots. Rubbed off with emery cloth and solved in a minute!

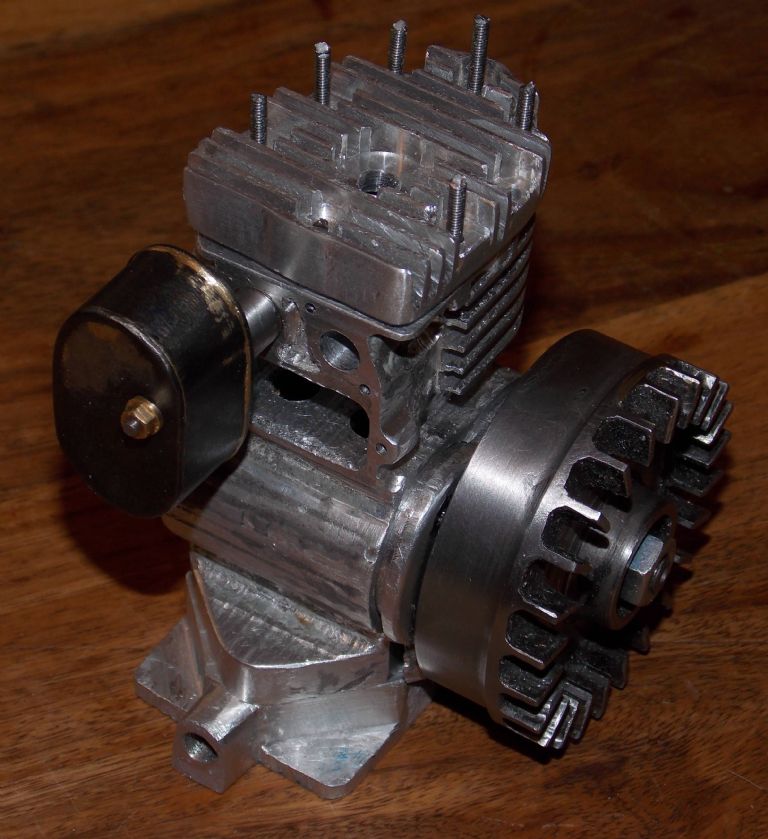

I have no idea if this will work, but I plan to make the flywheel of solid steel (as there is no need for a magneto recess as I will use a glow plug and 'simple' r/c style carb). I will also make the 'fan-fins' shallower to get the maximum metal in the body of the flywheel. I can also add a slightly over-size 'pulley' on the far side and use a disc or balanced crankshaft, all to max the rotating weight.

Can you suggest what sort of compression ratio to aim for -about 8:1?

Also would you go for a well-lapped CI piston or use rings on such a small engine, given I have no previous experience of making either?

Final question – space is very limited inside the crankcase so I thought of a solid big-end and a two piece crank with a small pin inside a big one (I've seen this done using a taper) The crank will be well supported with long bronze bushes either side.

Neil

Sub Mandrel.

))

))