Hello All,

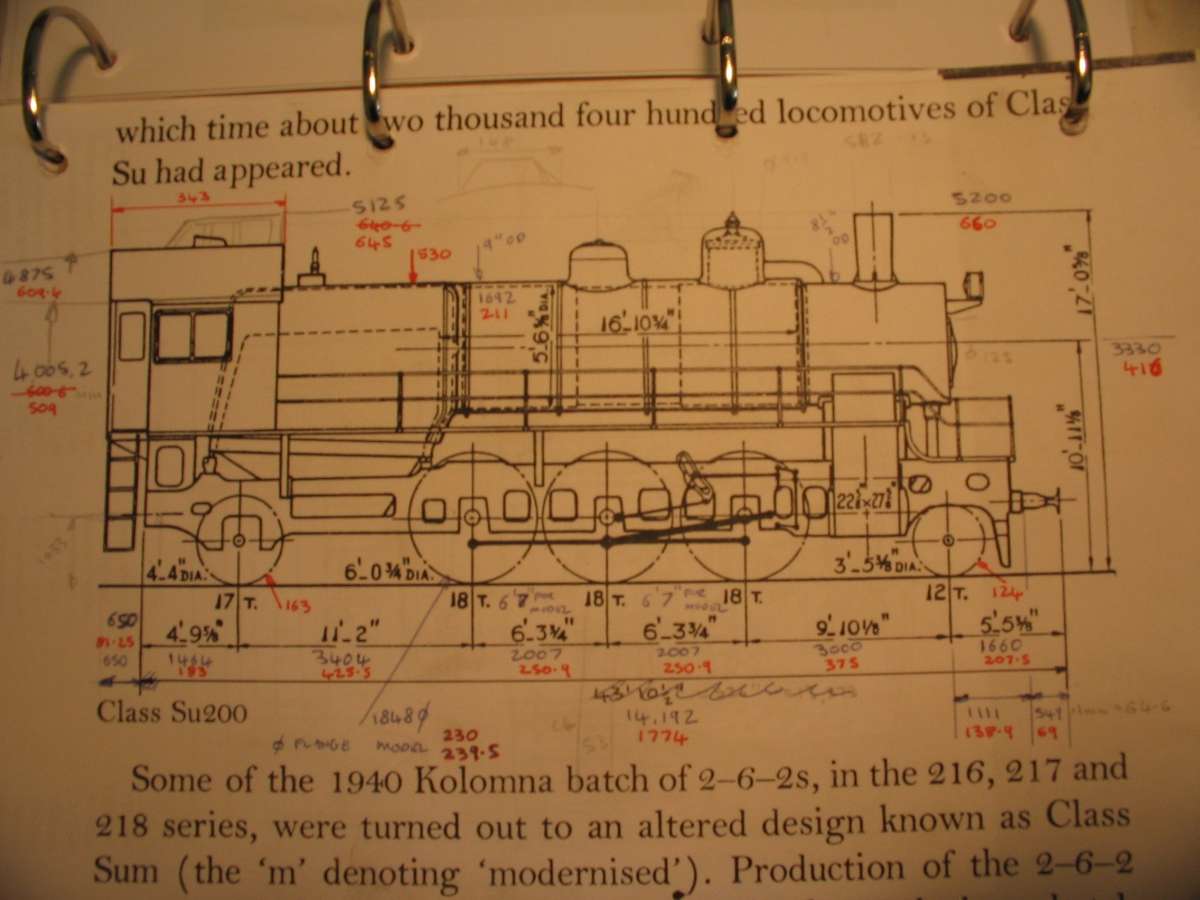

A few of the team here asked to see a bit more of the construction of the Su class in 7 ¼” gauge. After a long design and research period Metal cutting started in anger in 2003. First up was the tender as I wanted to have that ‘in the bag’ before I started on the loco. This project is almost entirely built from photographs, I was not able to physically see an actual preserved engine and the only ‘drawing’ I had at the start is the one reproduced her from Le Fleming and Price. I finally acquired a large number of drawings a couple of years ago, when the work was basically complete….. Luckily they confirmed that in most cases I was correct in my assumptions and the bits I got wrong are not noticeable.

The tender is on a welded steel backbone frame made from heavy box, the bogies are air braked with low pressure air at 20 psig on diaphragm cylinders, basically vacuum in reverse…. There is also a manual hand brake on the front bogie. Under test, the brakes seem to be reasonably effective. The body is 2mm brass throughout so that it is solid enough to sit on. It all makes for quite a heavy tender which can just be lifted by 2 people… There are a couple of air receivers under the tender frame for the brakes. There are also a couple of ball valves for the water output from the tender so that it can be uncoupled without draining if required. An interesting feature are the try cocks for the water level, presumably to check it when the surface is frozen over.

The hardest part was getting a good photo of the rear deck water fillers. In the end I managed to get a still capture from a TV video ( a great train journeys thing ) that showed just enough to be able to interpolate the position of the fillers. When I finally found a top image a number of years later I had luckily got it pretty well correct, but there was a lot of agonising and rechecking that fuzzy still to get to that stage. Building purely from photographs brings an interesting set of challenges, the cross checking of dimensions from several views takes time, but builds confidence that sizes are correct. Then back tracking to the key sizes on the general arrangement is the final check. It seems to have worked with only a few minor proportion errors that no one will notice.

Suspension is interesting, a combination of leaf and coil. That made life easy as I could harden and temper the leaf springs normally making them #@$ hard, then calculate the required spring rate on the coils…. Easy….

Finally there is a hand air pump located in one of the front cavities to top up the brakes if the steam driven compressor fails. That is a bit of the general paranoia here, there are a few examples of belt and braces redundancy on the loco that with hind sight were probably a bit too far. And at the other side a battery box for the rear lamps.

So that’s the tender…..

parovoz.