I am machining my first steam engine, a Stuart Victoria.

The first cylinder I bored out I made a right dogs dinner of it! I used a mandril through the rough casting bore to position it central in a 4 jaw chuck. Anyway that resulted in a way off centre bore.

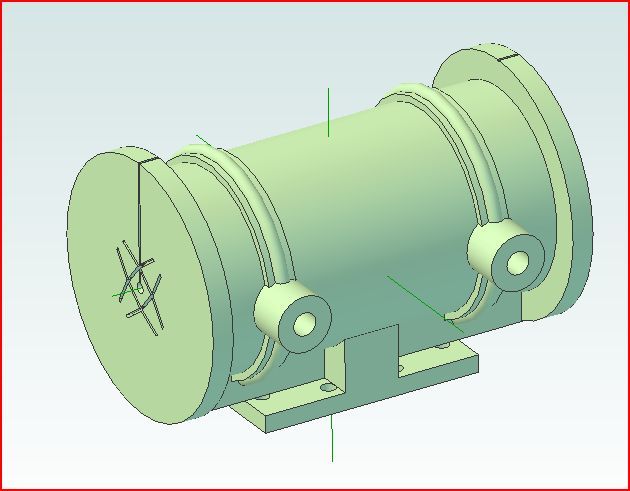

Now I am on cylinder # 2. Looking at various videos and photos of how other people have done this, it seems the first operation is to machine the valve chest surface flat. I have done this and now have it on an angle plate on the face plate.

The thing I am struggling with now is how the get the cylinder 'all lined up'. I can not really clock the outside diameter of the cylinder as it is not completely round. If I clock on the inside of the rough bore, that might be true on the outside face but the cylinder may not be aligned squarely along its axis. At least that's what I think. Maybe I am wrong?

I have passed a 15mm dia bar through the lathe spindle and out through the cylinder to see if I can roughly eye it up as shown in the photo. This may look central on the outside face but maybe the inside face (against the face plate) is not centrerd?

Its a bit of a difficult thing to explain but maybe someone understand what I mean and can point me in the right direction.

Thanks

JasonB.

JasonB.