Day 18.

The Replacement Cylinder.

The replacement cylinder finally arrived and I was hoping that with the Keats Angle Plate it would be much easier to setup, but no not for me! I'm sure it will come in useful from time to time but as the center of the bore had to be offset on the Plate due to the shape of the Cylinder Block I found it more difficult and returned to the ordinary Angle Plate Setup. This gave me a real headache again until (and it seems blindly obvious now) I realised that it was no good trying to setup the bore to run true as this as supplied was not central through the block – it was the outside of the flanges that needed to run true…. I then found it much easier to setup on the faceplate off the lathe and then take the whole lot to the lathe. Not sure what is the normal way to do this but I had no joy with the DTI as the outside surface of the casting was so rough, I used some parallells and the circular markings on the faceplate to get the flanges running true – to the eye anyway. The result seems to be ok other than lots of scuff marks on the Cylinder Ends from so many in and outs in various attempted setups – lots of lessons learned and I'm sure I would not repeat next time… I'm hopeful that the end face should be square to the bore at the gland end..

So its so far so good with the Cylinder and on to the Steam Chest next.

The replacement Cylinder as supplied – needed quite a bit of filing, the tops in particular of the 'waste' material seemed to be incredibly hard…

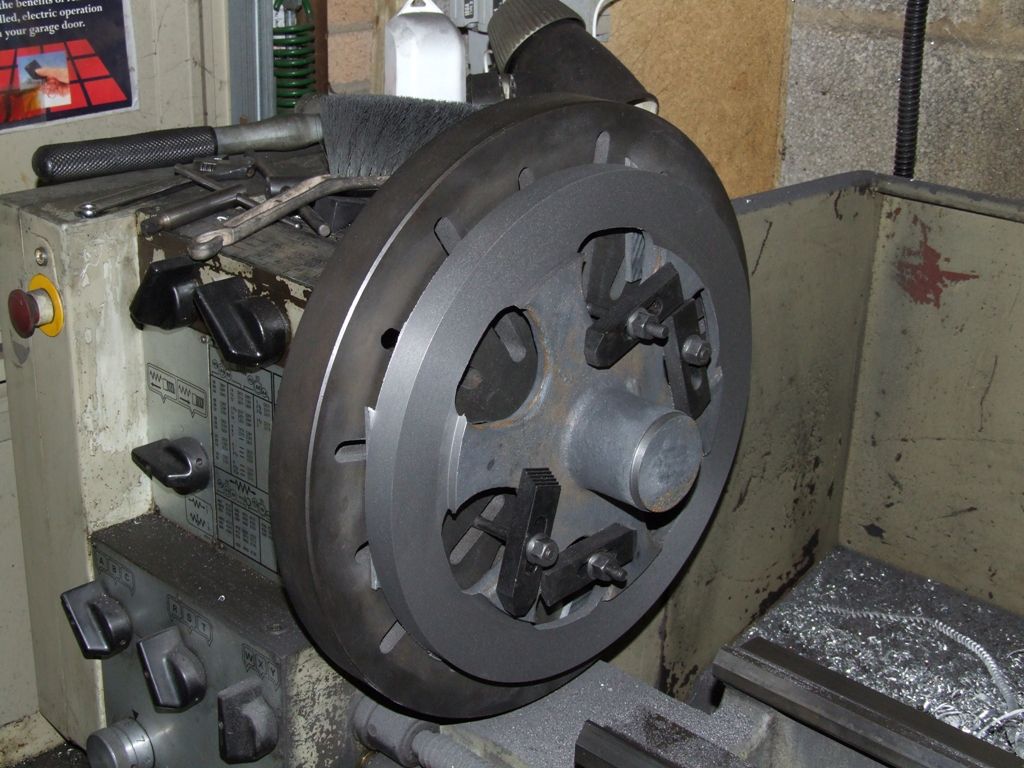

The Keats Angle Plate – Not successful for me due the bore being offset in the block and making setup difficult..

The Final Setup used for boring.

The Final Bore.

2nd attempt (top) and the result of incorrectly (and wrongly) setting up on the bore itself the 1st time around (bottom).

Regards

Allan.

GarryC.