Hi Jason and Julian

Julian's post has prompted me to try and find out a little more about this as I know nothing at the moment!

This off wikipedia has at least given me some idea now..

When on the move, a steam locomotive requires steam to enter the piston at a controlled rate.[3] This entails controlling the admission and exhaustion of steam to and from the cylinders.[3] Steam enters and leaves the valve through a steam port, usually at the middle position of the piston valve.[3] Where the valve is in contact with the steam ports, a consideration of the "lap" and "lead" is required.

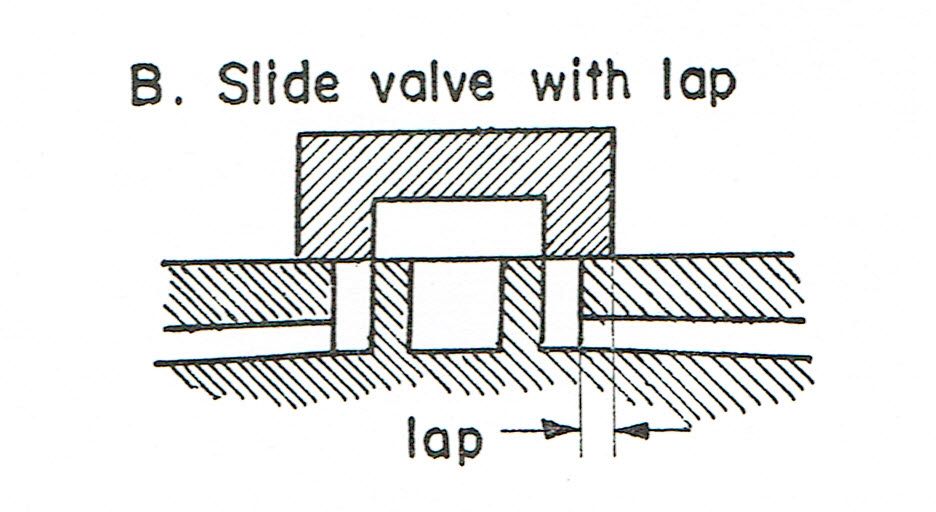

Lap[edit]

The "Lap" is the amount by which the valve overlaps each steam port at the middle position of each valve.[3] However, there are two different types of "Lap."

The first kind is the "steam lap," which is the amount by which the valve overlaps the port on the live steam side of the cylinder.[3] Secondly, there is the "exhaust lap," which is the amount by which the valve overlaps the port on the exhaust side of the cylinder. "Exhaust lap" is generally given to slow-running locomotives.[3] This is because it allows the steam to remain in the cylinder for the longest possible amount of time before being expended as exhaust, therefore increasing efficiency.[3] shunter locomotives tended to be equipped with this addition.

The "Negative exhaust lap", also commonly termed "exhaust clearance," is the amount the port is open to exhaust when the valve is in mid-position, and this is used on many fast-running locomotives to give a free exhaust.[3] The amount seldom exceeds 1/16 in. when exhaust clearance is given; the cylinder on both sides of the piston is open to exhaust at the same time when the valve is passing through the mid-position, which is only momentary when running.[3]

Lead[edit]

The "lead" of the valve is the amount by which the steam port is open when the piston is static at front or back dead centre.[3] Pre-admission of steam fills the clearance space between the cylinder and piston and ensures maximum cylinder pressure at the commencement of the stroke.[3] "Lead" is particularly necessary on locomotives designed for high speeds, under which conditions the valve events are taking place in rapid succession.[3]

All very interesting I thought.

Cheers

Allan

Edited By Allan. on 28/02/2014 19:00:34

Edited By Allan. on 28/02/2014 19:03:21

Edited By Allan. on 28/02/2014 19:20:38

GarryC.