Ignoring, for the moment, the various Design Changes to components, and working from basics..

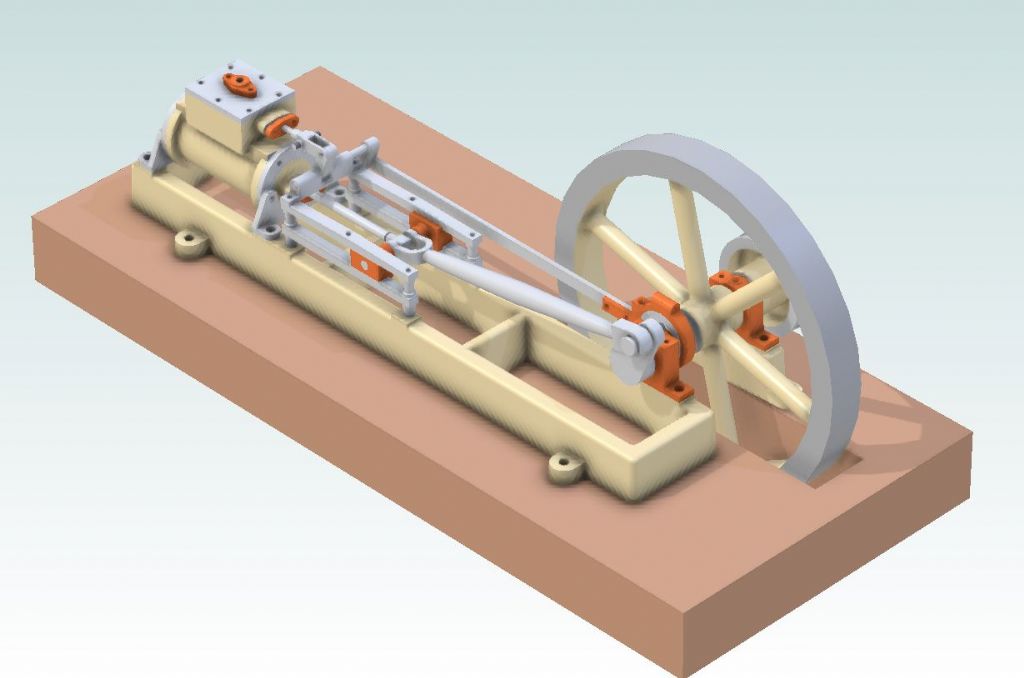

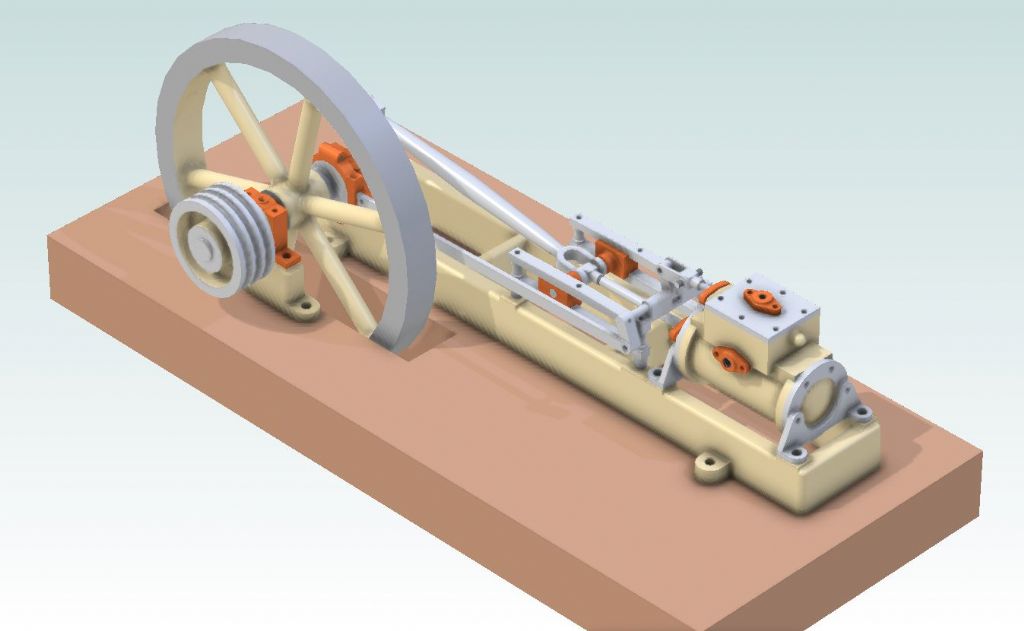

ASSUMING that the cylinder centreline is the same height from the bedplate as the Crankshaft centreline, the piston stroke will be twice the throw of the crankshaft ( [Crankpin center to Crankshaft centre] x 2 )

To allow the engine to rotate, the distance between the standards for the Slide Bars must be greater than the Stroke. This difference will be twice the design clearance between Crosshead and Slide Bar standards.

The Con Rod Centres should be Crank Pin Centre to Gudgeon Pin centre, with the Cross Head clear of the Slide bar Standards by the designed Crosshead to Standard clearance, at Inner and Outer Dead Centres.

The Piston Rod length should be such that at Inner or Outer Dead Centre, the Centre of the Gudgeon Pin bore just provides the clearance at each end of the cylinder.

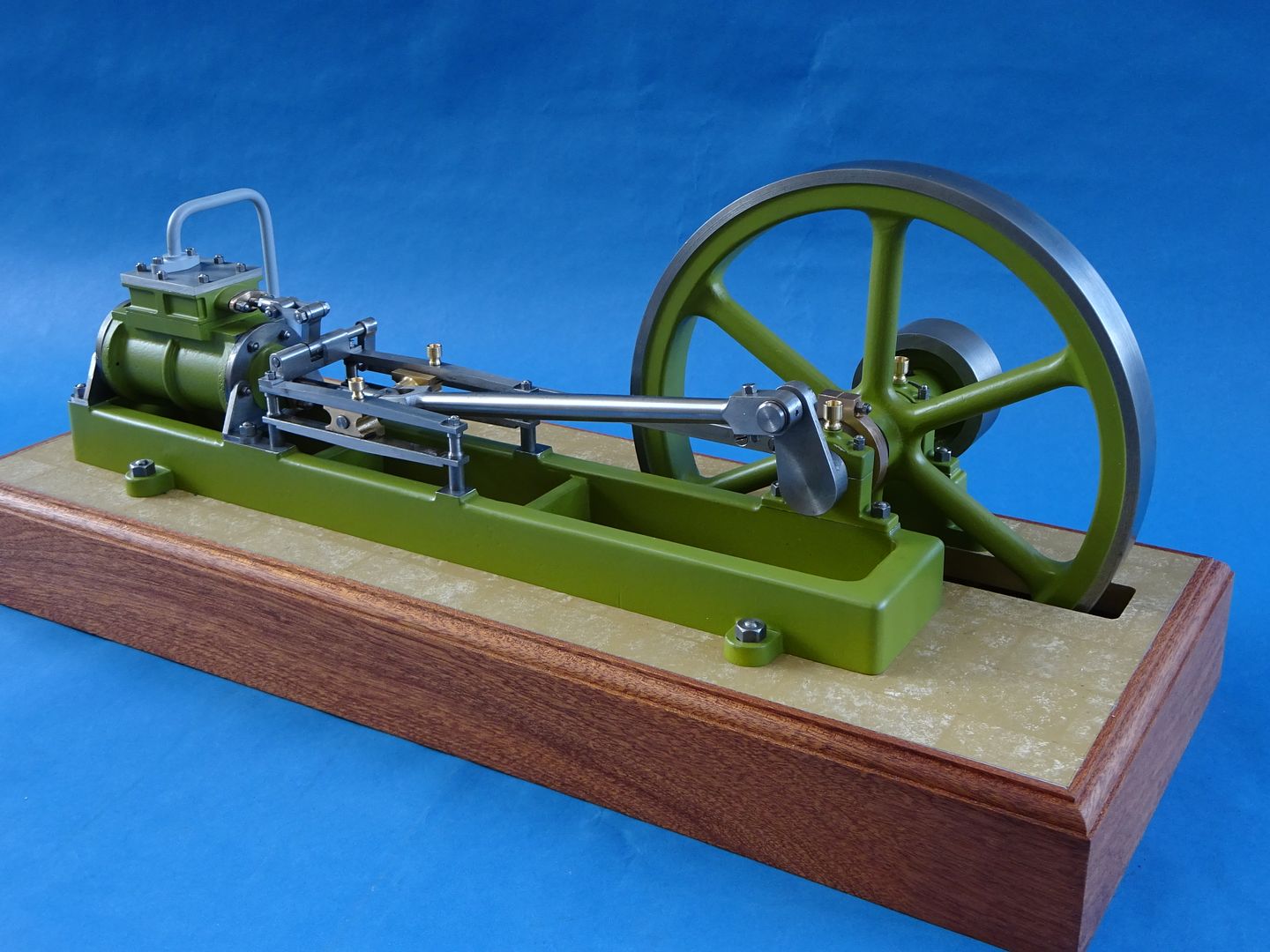

Some designs might attempt to cater for the difference in effective Piston area, on each side, by allowing more clearance on the Piston Head side than on the Rod side. The rights and wrongs of this approach should not enter into this discussion, unless the basic design dimensions suggests that this is the case here.

Far easier, (but theoretically wrong, perhaps ), to aim for equal clearance at both ends.

Having taken some dimensions, it should be possible to find the dimensions for Con Rod Centres, and Piston Rod length, for THAT particular engine, which may differ from the dimension shown on a drawing, especially if the drawings are at different Design Change levels.

HTH

Howard

JasonB.

JasonB.