If you introduce recursion then there is a danger that the loop will never terminate. If the Stuart #1 is to be an exact scale model of itself how do you build the first one? Even though we often say something is a 12″ to the foot replica of itself, it is not really a very meaningful sentence.

The small engines that are intended for a job of work are in fact small utility engines, not scale models.

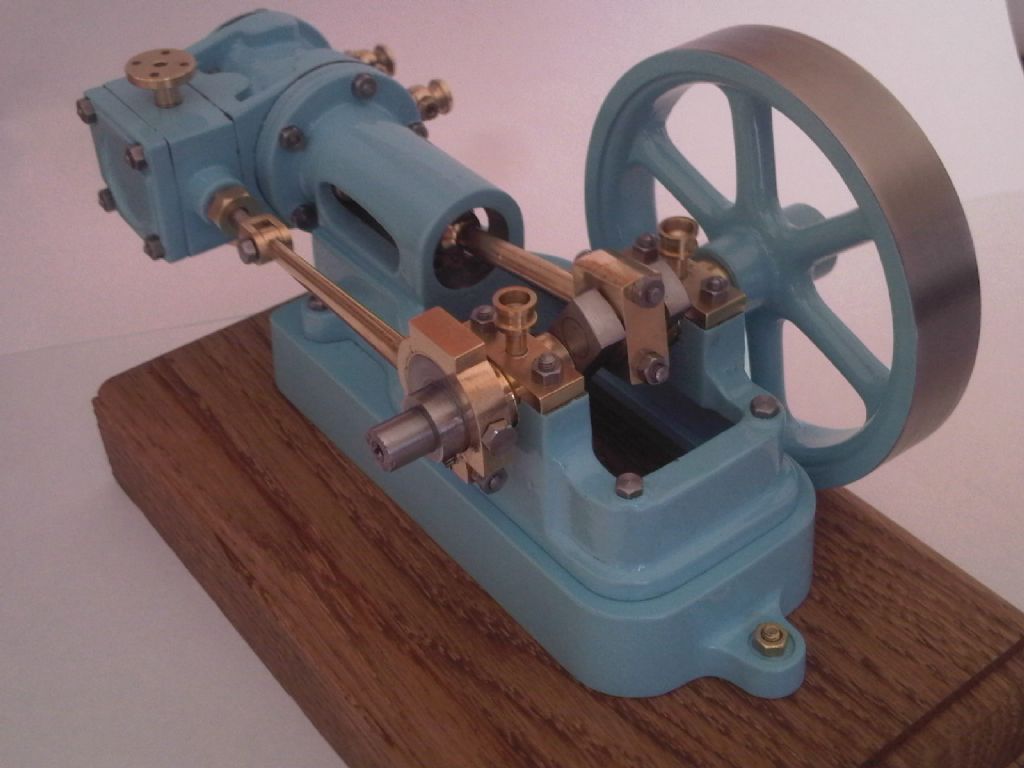

The compound launch engine as I understand it is actually a model sized engine, (5 and a half inches high) however the Stuart 6A is a similar sort of engine that is big enough for a modest steam launch. The 5A is another engine that is solid enough and big enough for a small boat. The number 1 has the same bore and stroke, but is not suitable for heavy work since its proportions, especially the bottom end journal sizes, are not really up to heavy duty. It is built to look like a scale model of a full size engine. I suppose that makes it what some would call “free lance scale”, which is probably an oxymoron but most people would understand what is meant…a model of something that might have been rather than something that actually was built. I’m not knocking them for this, I have built several and really like them. (10 V, 2 Number 1’s, a double 10 and a Stuart lathe.)

ETW was of course right, a true scale replica is quite hard, since all the tiny bits on the real thing get really tiny in a model. The bigger the engine, the harder it tends to get, since there tend to be some small parts somewhere in there that get really difficult to make, governors for instance. Of course part of the art is knowing what it is reasonable to omit, and some bits like governors don’t necessarily need to work fully.

regards

John

Sub Mandrel.