So on to the cylinders – I needed to clean them up to get an idea of the diameter to machine into the modified feet blocks.

I actually have three – one was damaged when I got it; looked like whatever was used to separate it from its runner might have cut into the valve face:

There isn’t much machining allowance on there, so I sent a photo to Stuart Models who immediately sent another (excellent service). The intention is to use the damaged one for a machining test run, so I bodged some JB Weld into the cuts:

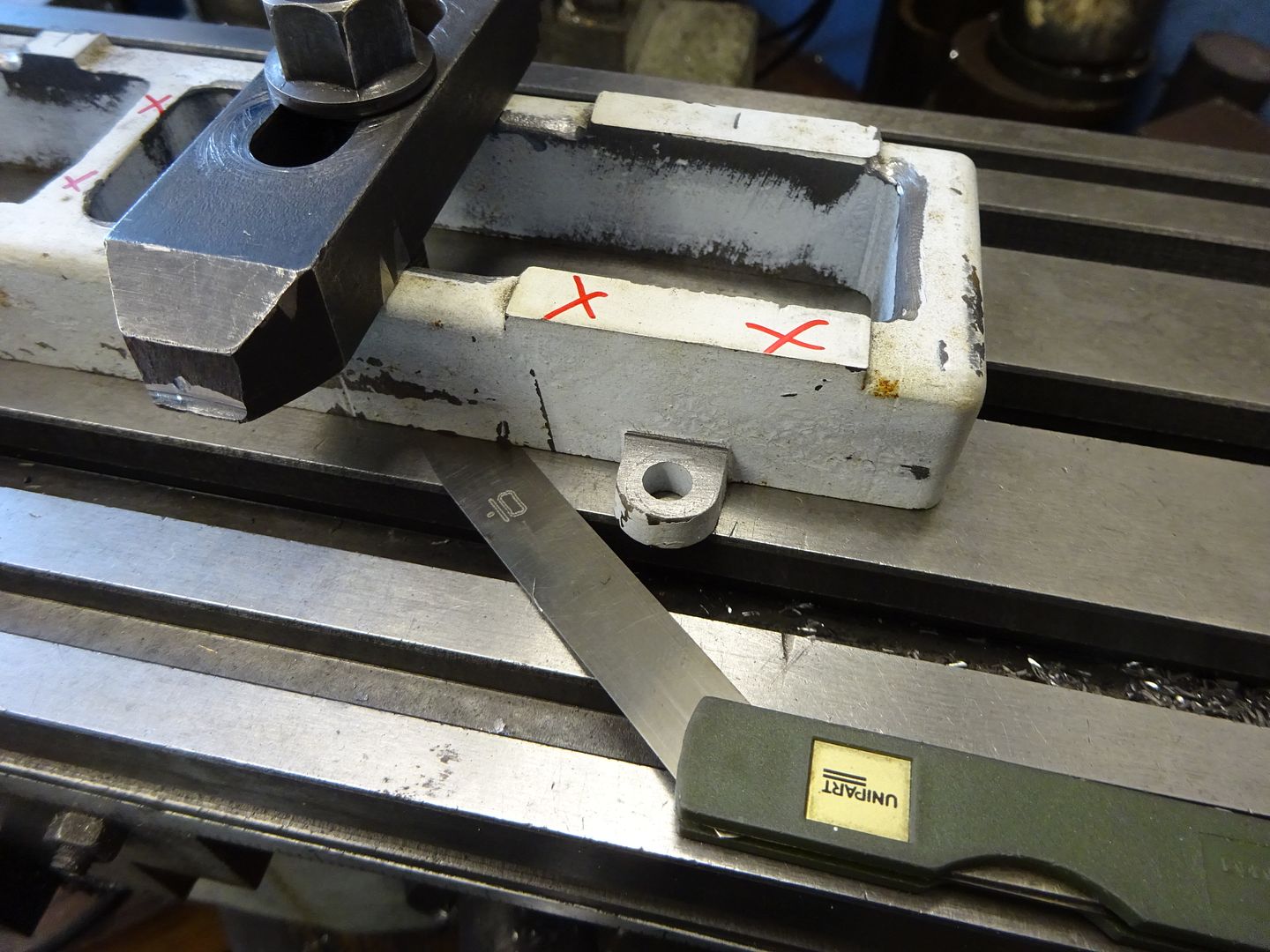

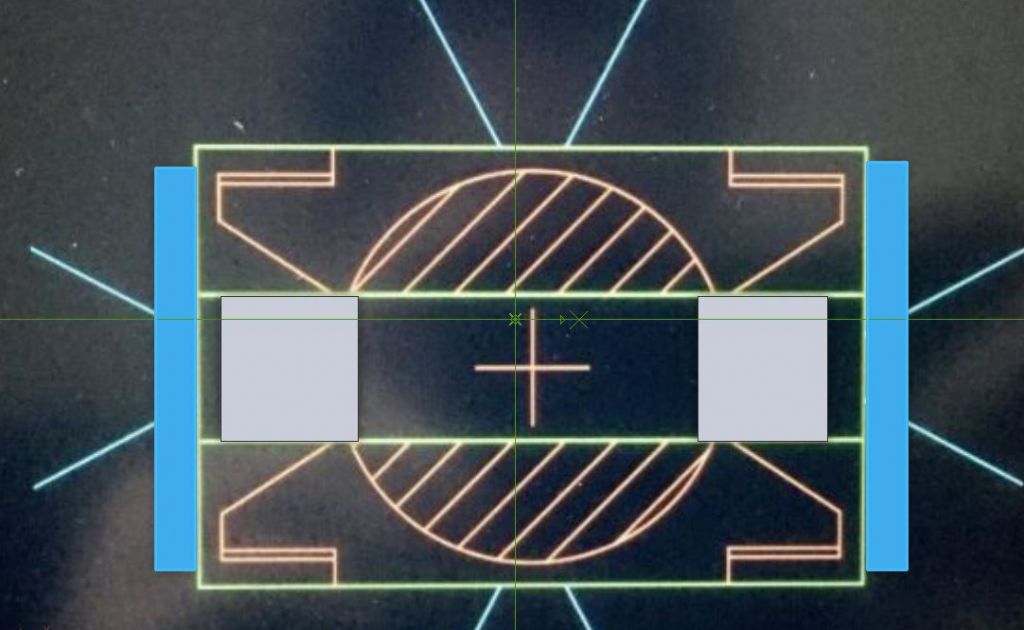

I cleaned the other two up, initially with a wire brush:

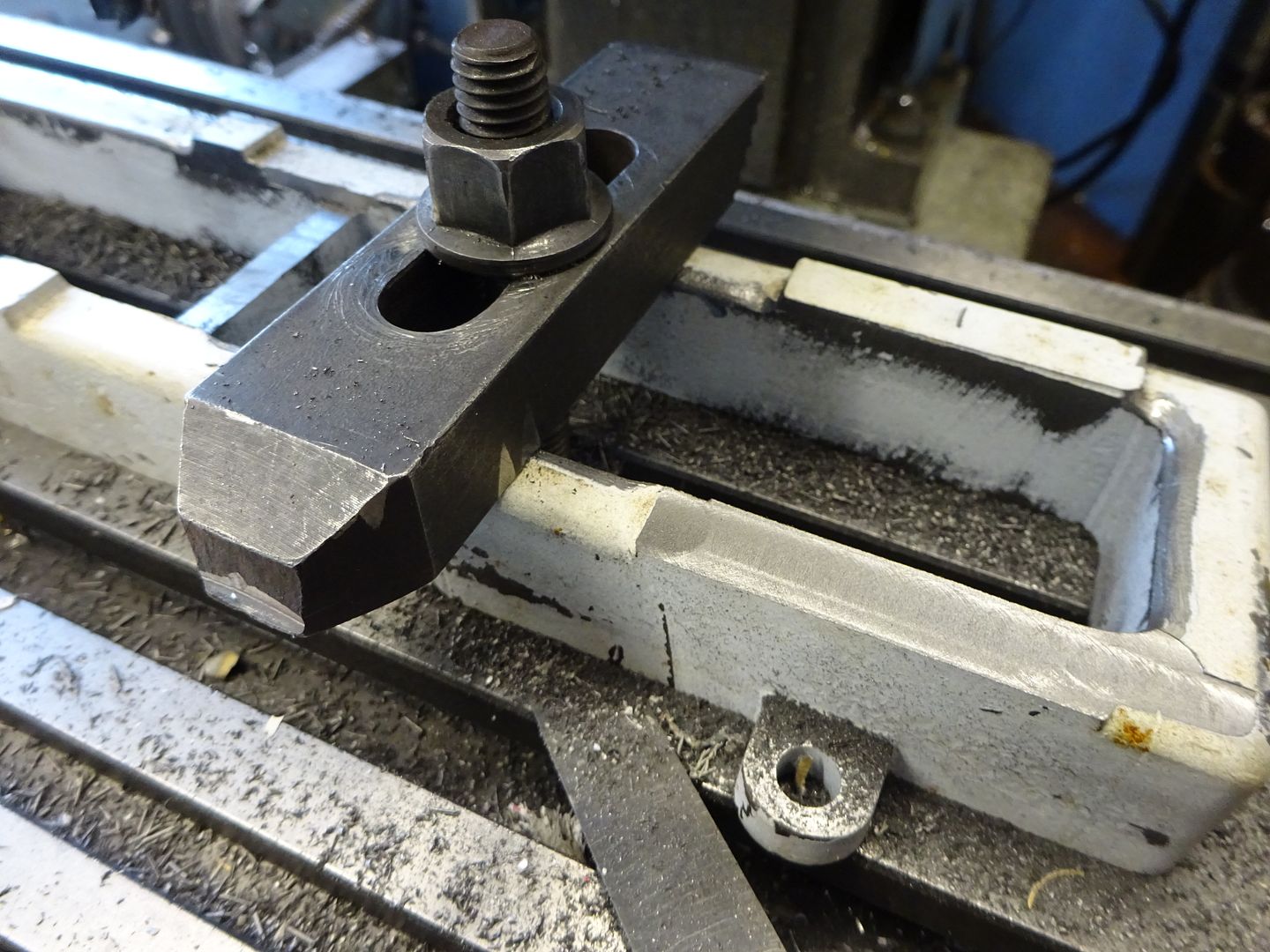

and removed the drain cock pads with a file, in preparation for fitting the feet:

But then I noticed quite a bit of scaling on the surface, which wouldn’t come off:

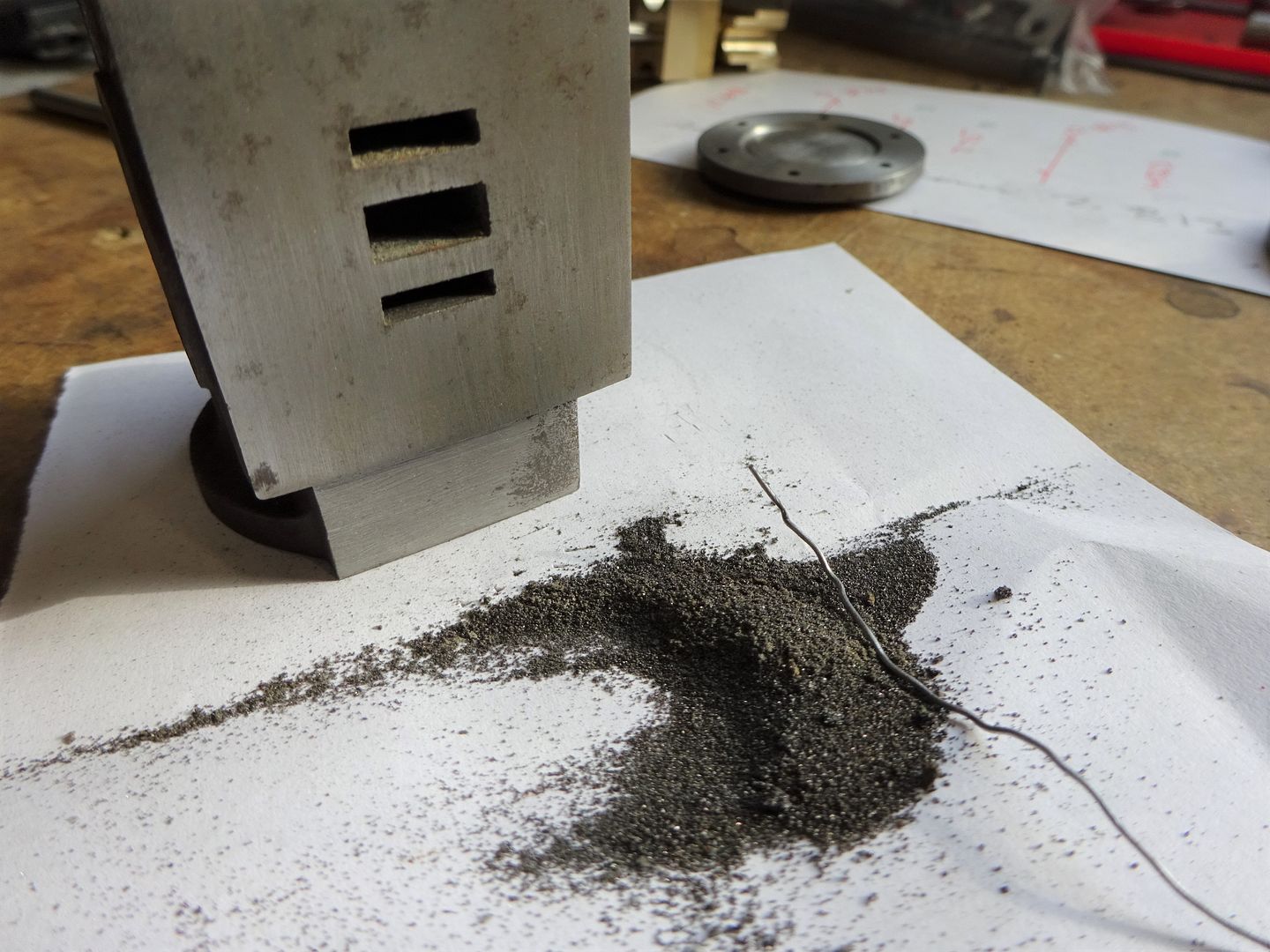

The file just skated off it, so I resorted to a grinding bit in the Dremel:

Which seemed to do the trick, but there’s still a lot to remove. It’s worse on one casting than the other two. I wonder if putting them in the fire made it worse. I’m thinking of trying to remove it from the cylinder bore as well, before machining. I now understand What all the fuss is about regarding casting skins, and them ruining tools. There was none on the 10V.

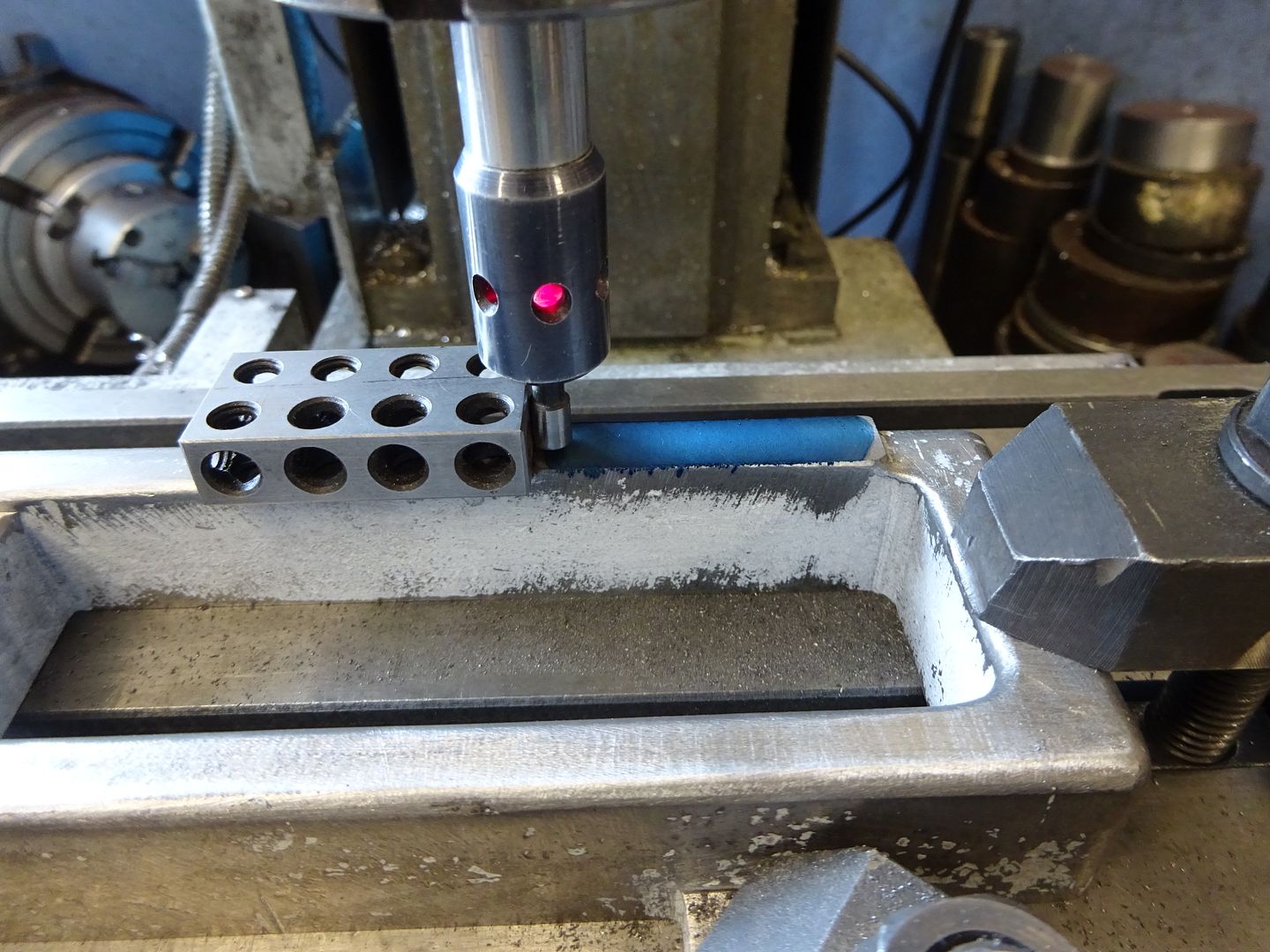

Also began poking the steam ports with wire to remove any residual mould sand – again, one was much worse than the other:

So current status is two are about 50% fettled, still waiting for the JB weld to set on the other:

BTW the nominal diameter seems to be about 33.5mm, so I’ll machine the feet to 34 and hope for the best; the JB Weld should make up the rest.

This all took longer than I thought, so the feet will have to wait for a few more days…

JasonB.

JasonB.