Despite it being pretty cold in the garage, I’m getting itchy fingers again to progress with this one. Too much plastic modelling recently, and it’s bad to get demoralised by daft setbacks like this was.

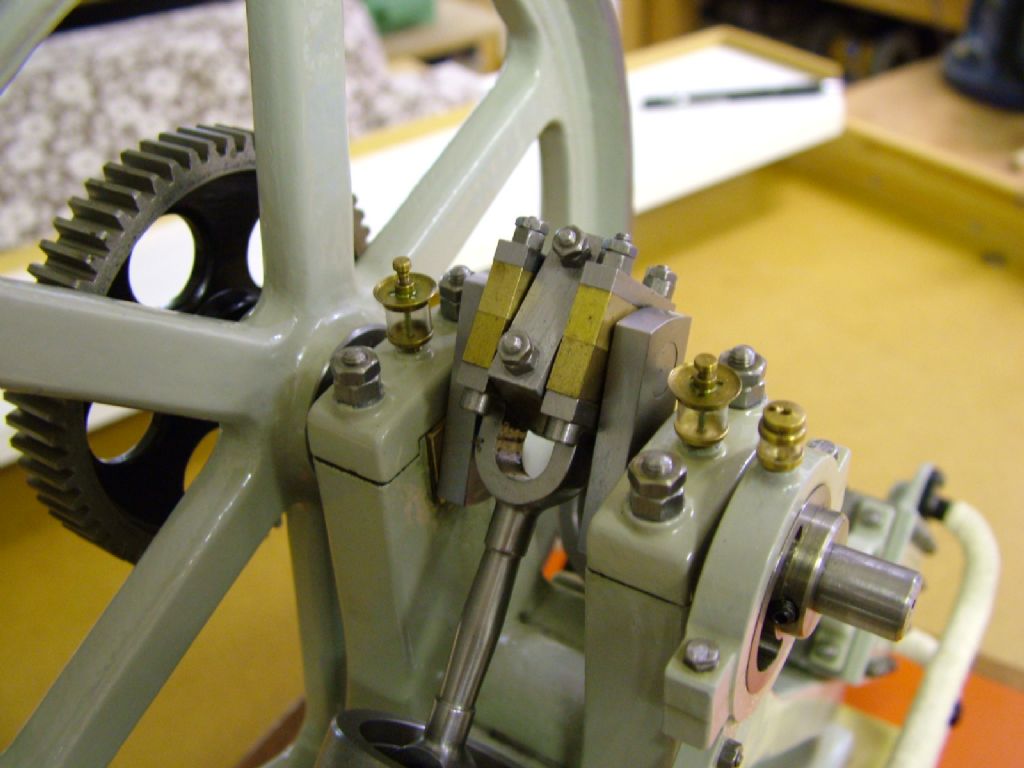

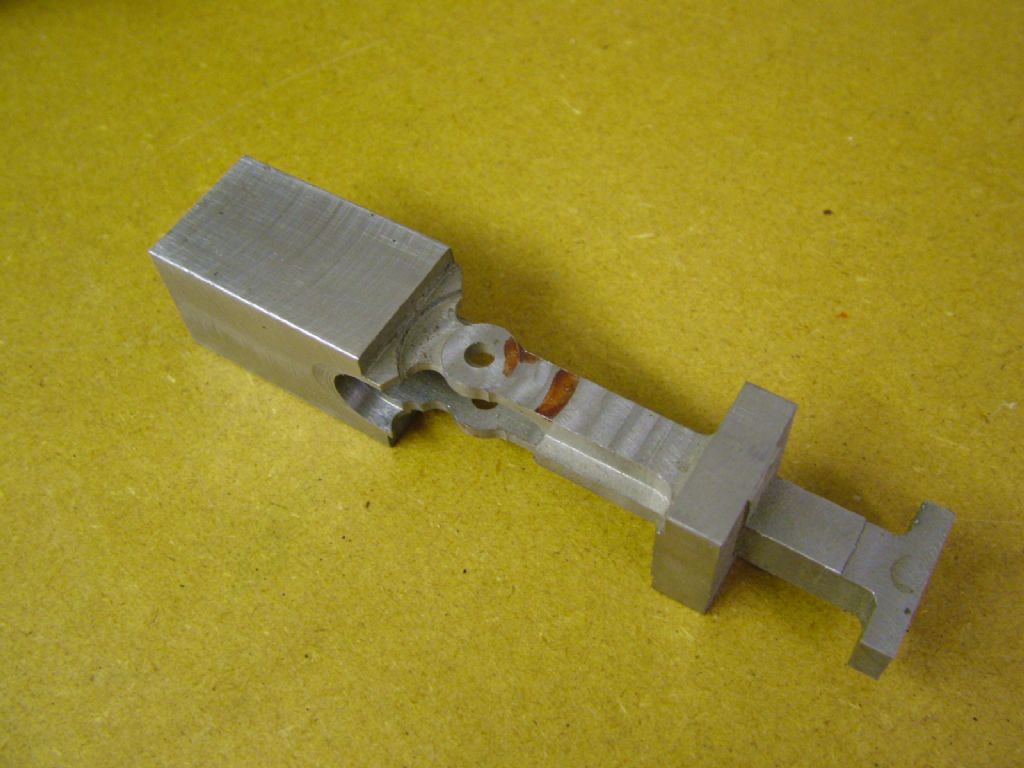

Briefly, I’d previously slightly modified the spacing between the crosshead slides, but forgot to widen the forks to suit. Result is a gap between the brasssliders and the forks, approx 1 mm per side:

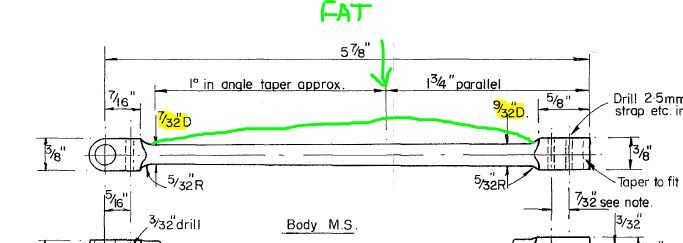

Further to Ramon’s suggestion of rescuing the too narrow forked ends with top-hat bushes, I drew up this today.

The idea is to make 4 bushes. The stub diameter is 6.5mm since I have a 6.5mm slot drill.

I would set up each fork on an expanding mandrel/bolt in a collet so that one side of the fork is held concentric, then use a slot drill in the tailstock to bore a locating hole in the outer fork. I’d eventually repeat this on all four prongs – obviously I’d need two diameters of mandrel.

I’d then make 4 top-hat bushes, with their flanges oversized. I’d make these a tight press-fit into the forks, and solder them in place.

Then I’d use a lathe tool with a 0.3mm tip radius to machine the flanges to match the adjoining brass slider boss diameters.

I’d re-ream them to 5mm sequentially, so that once one fork prong was bushed, the opposite existing, unmodified, 5mm hole would guide the reamer into the opposite repair bush which had been drilled to pre-ream size. Then repeat when the opposite bush was fitted.

Then I’d face the new bushes to the correct width.

Hopefully the joint would not be too visible.

Any thoughts? Should I just start again, re-make the forks and be done with it? Re-make the brass sliders with extended bosses? I’m not fussed either way at this stage, so long as it’s right in the end.

JasonB.

JasonB.