Ah – I’d already forgotten about holding the square stick!

This evening I got the straps set up in the mill and decked the bolt faces, milled the sides to clean-up and to size, and drilled/tapped the holes. Then split and milled the cut faces.

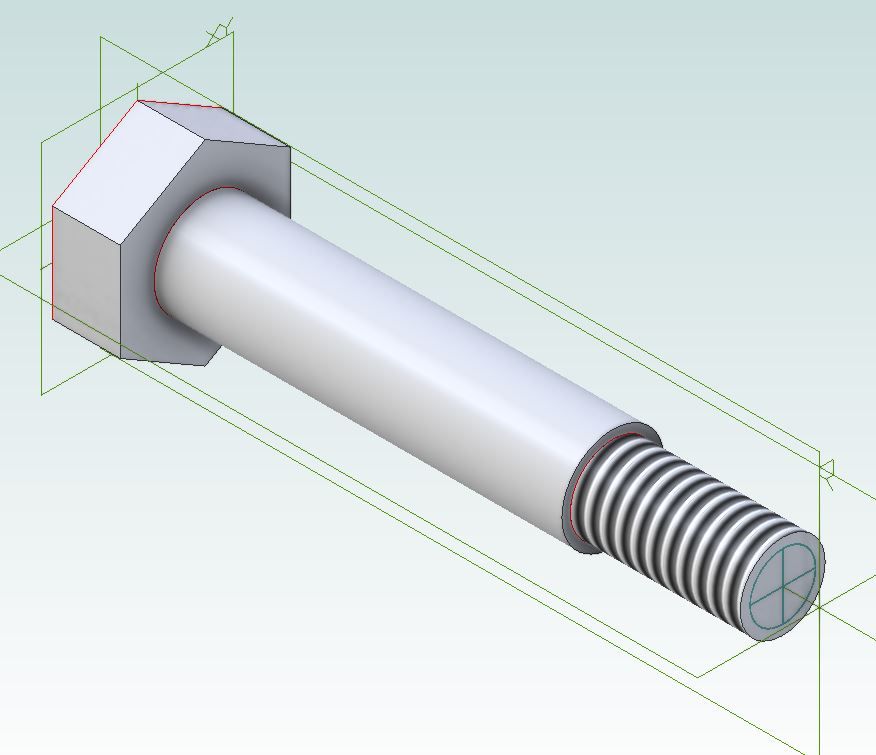

I drew it so that a flat of the 7BA bolt head would be against a milled flat, and the nuts would turn without hitting a milled edge, nor overhang the side.

Not much problem until I tried the bolts. To cut a long story short, the centre spacing is fine, but the centres are both offset to one side. No idea why, since everything was offset from the same zero datum in the middle of the two outer faces. The bolt/nut flats were also milled from the same datum, and their sides are all spot-on according to my depth gauge.

The bolts and nuts look like if there were correctly centred, my dimensions would have been spot-on for retaining the bolts and turning the nuts…of course everything needs further machining to get to size, but it was a good trial of how things would fit

So I need to either:

1) Use a mill to make them oversized, but the correct centres

2) Fill the holes somehow and re-drill

3) Get a new casting and start again.

Slight worry is that they will turn out the same again – I have no idea why they’re offset to one side. They were centred on a freshly milled pad, and there appeared to be no issues during drilling.

There is excess material everywhere, apart from the overall width (the castings were very tight on the excess there for some reason) so plenty of room for adjustment…apart from where I now need it. Seems like overhanging fasteners are a recurring issue for me!

JasonB.

JasonB.