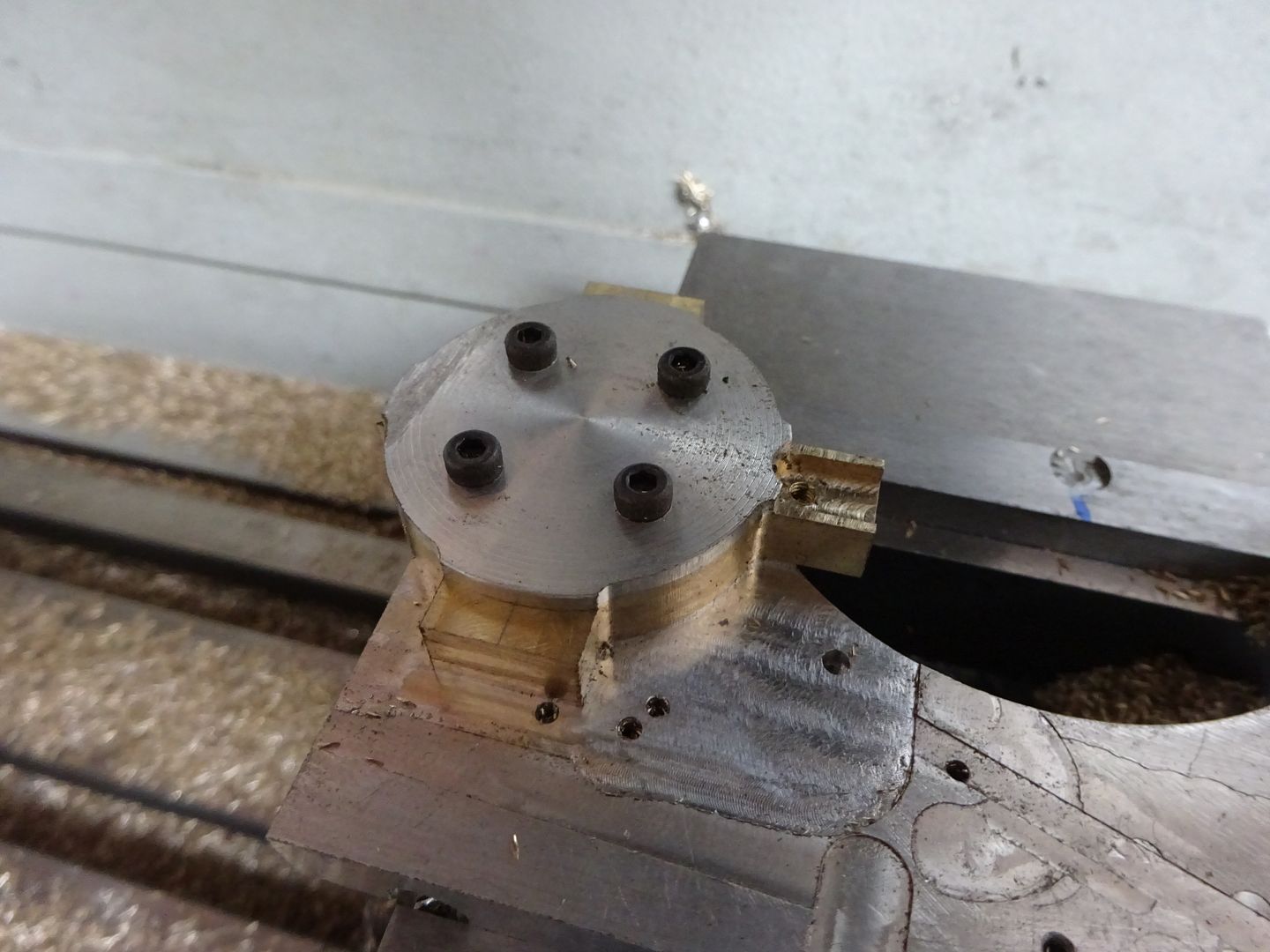

I'll try the eccentrics next. I've got the castings, and I think the bar is what I got for the sheaves:

I'd appreciate some help, becasue I find the description of how to machine the sheaves confusing to say the least.

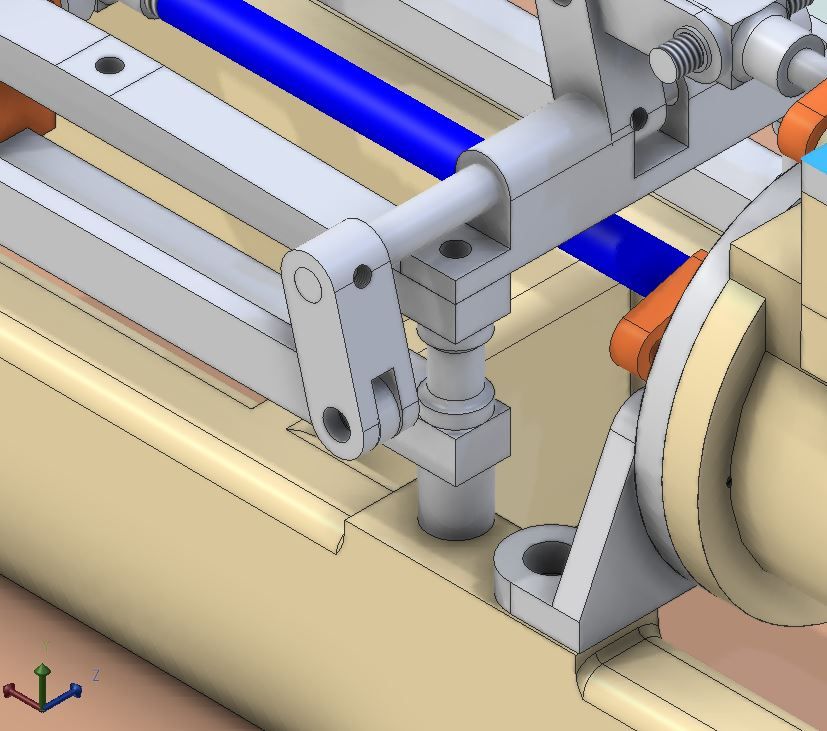

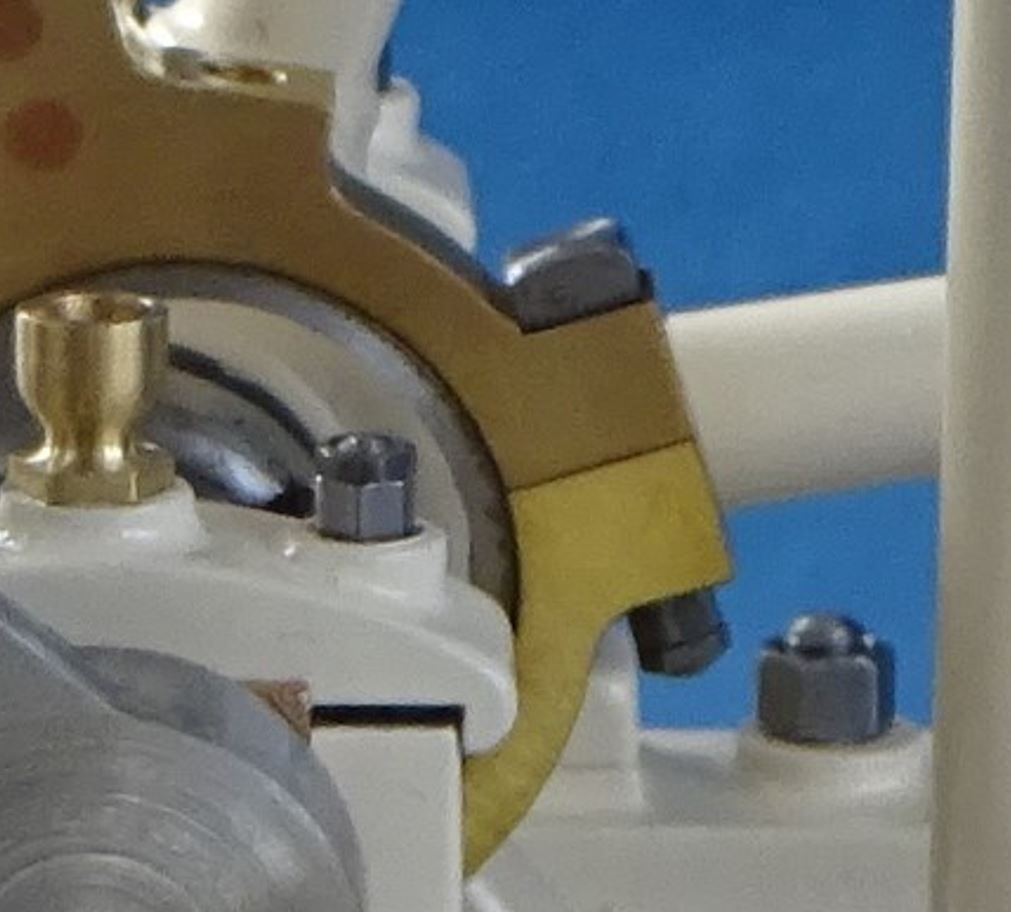

For the straps (which Id like to fully machine), I was going to do it like this:

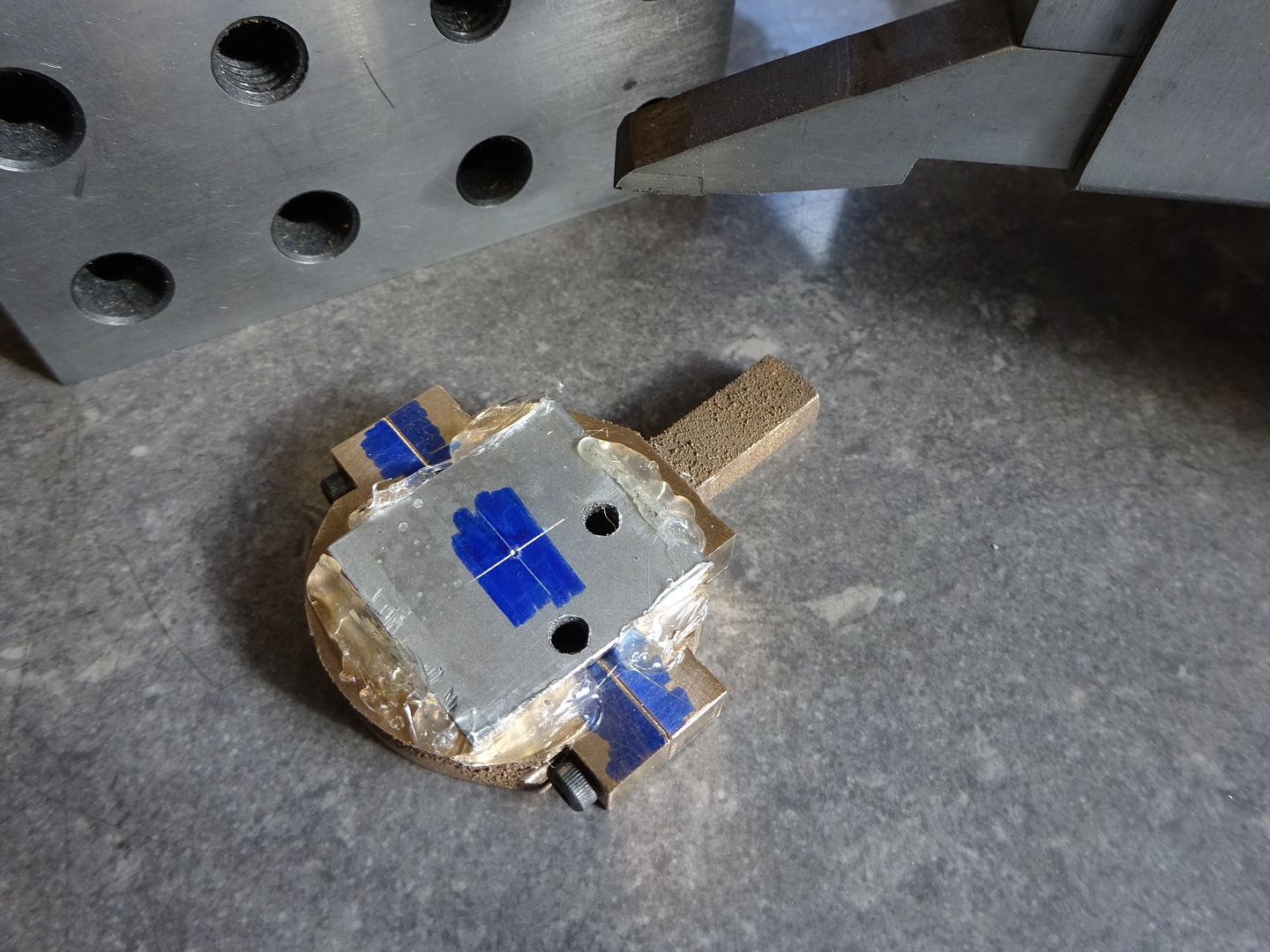

1) Clean up the castings with files.

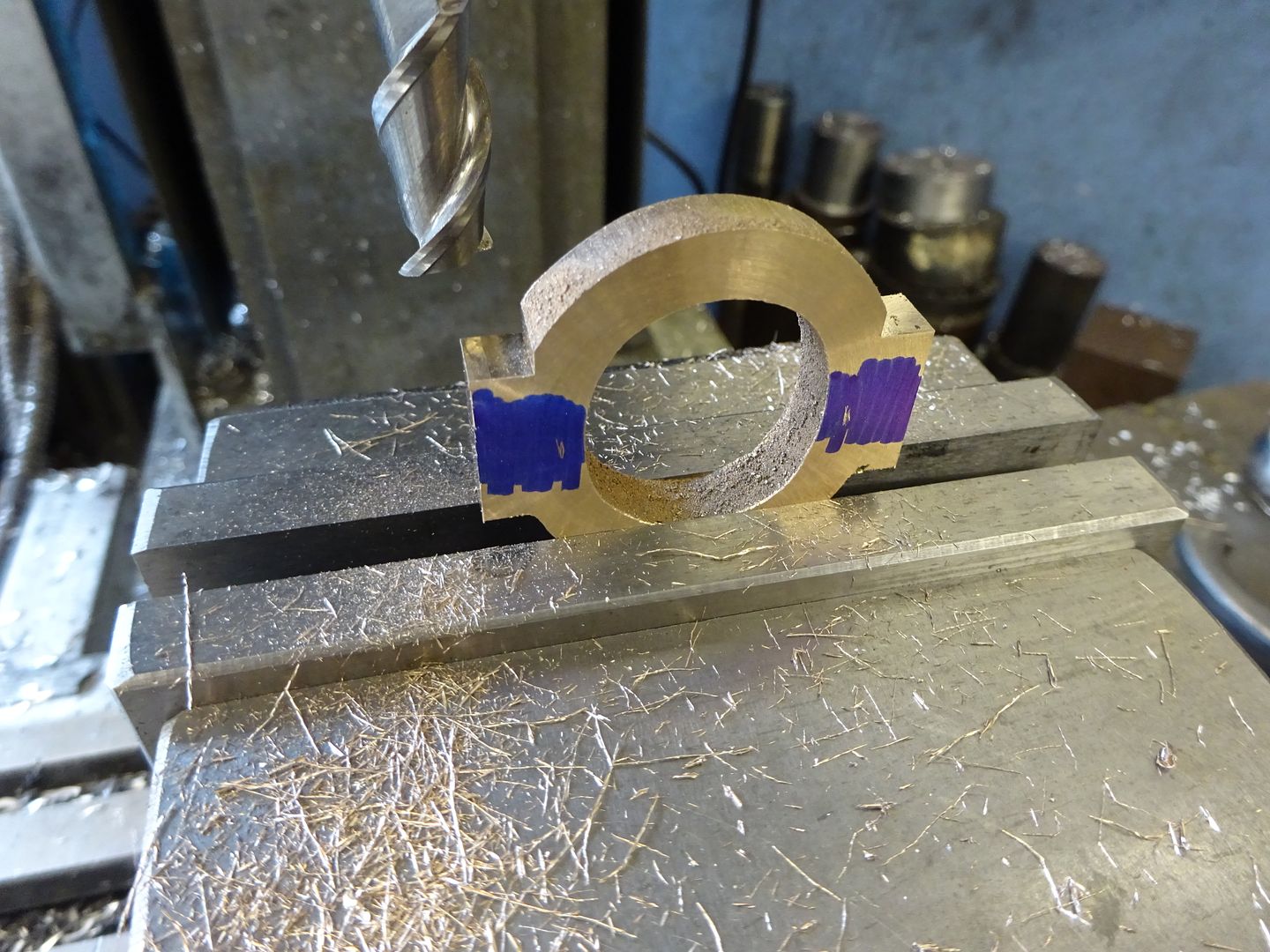

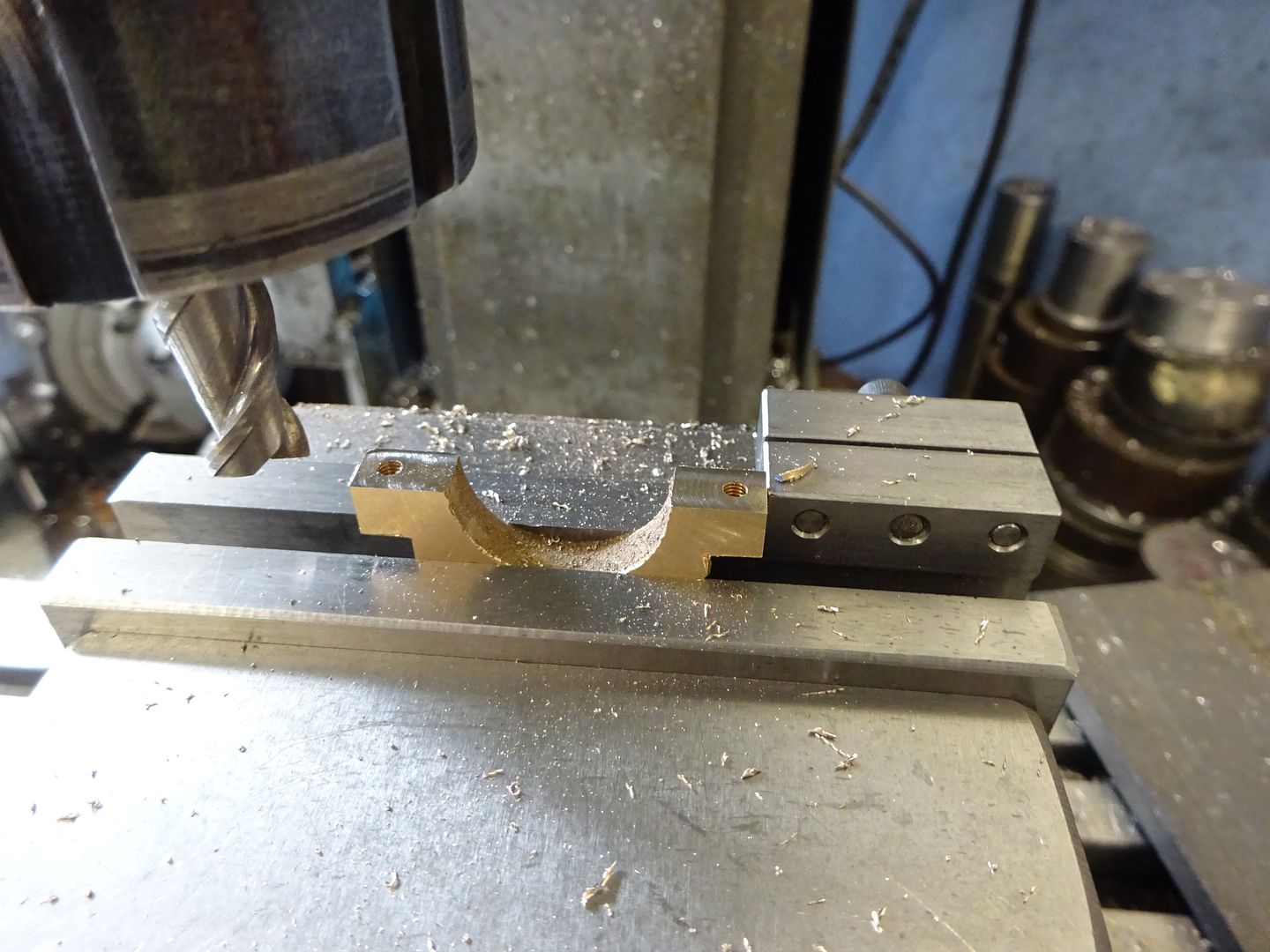

2) Set in milling vice with the clamp hole faces vertical & drill the holes.

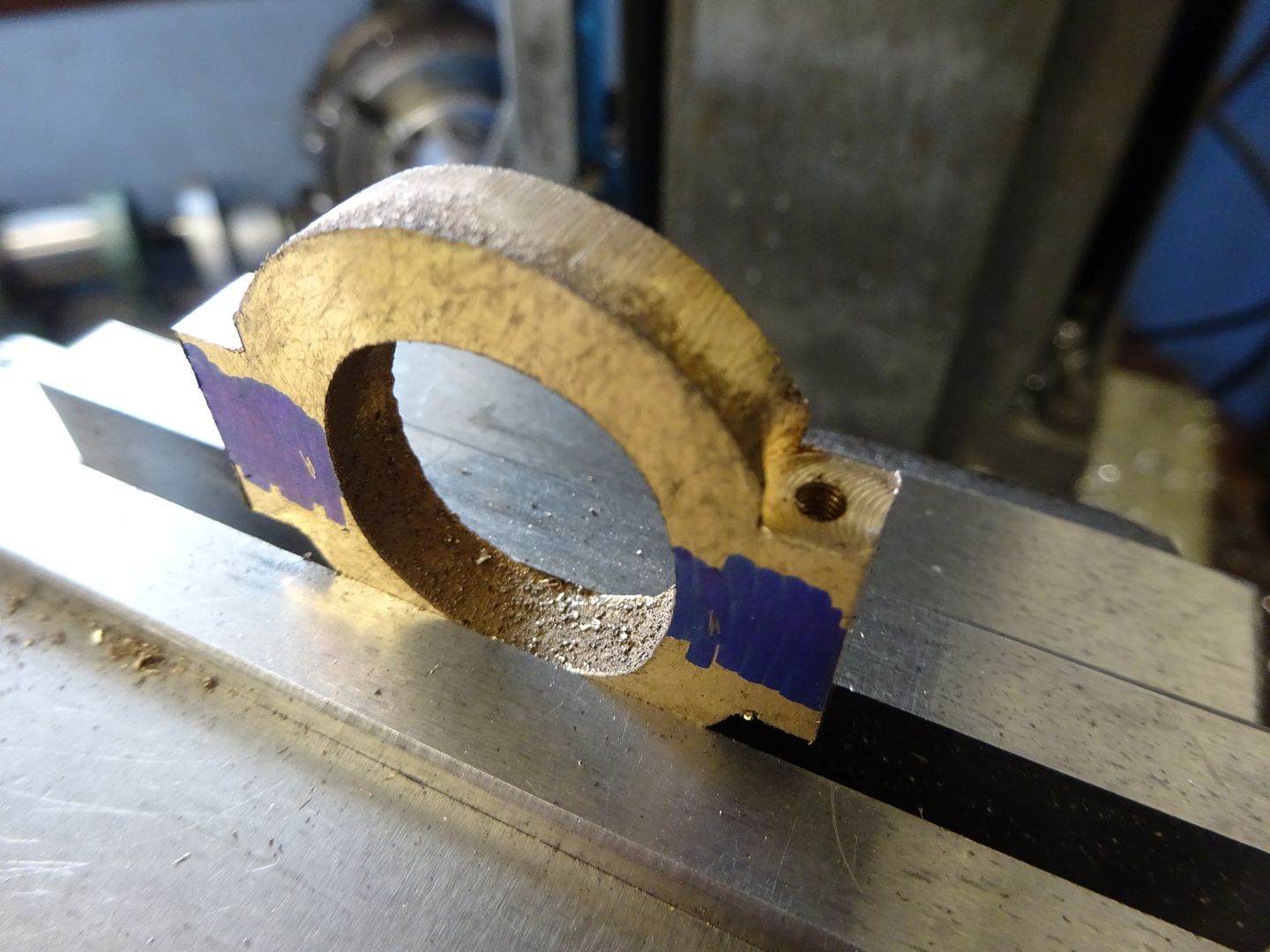

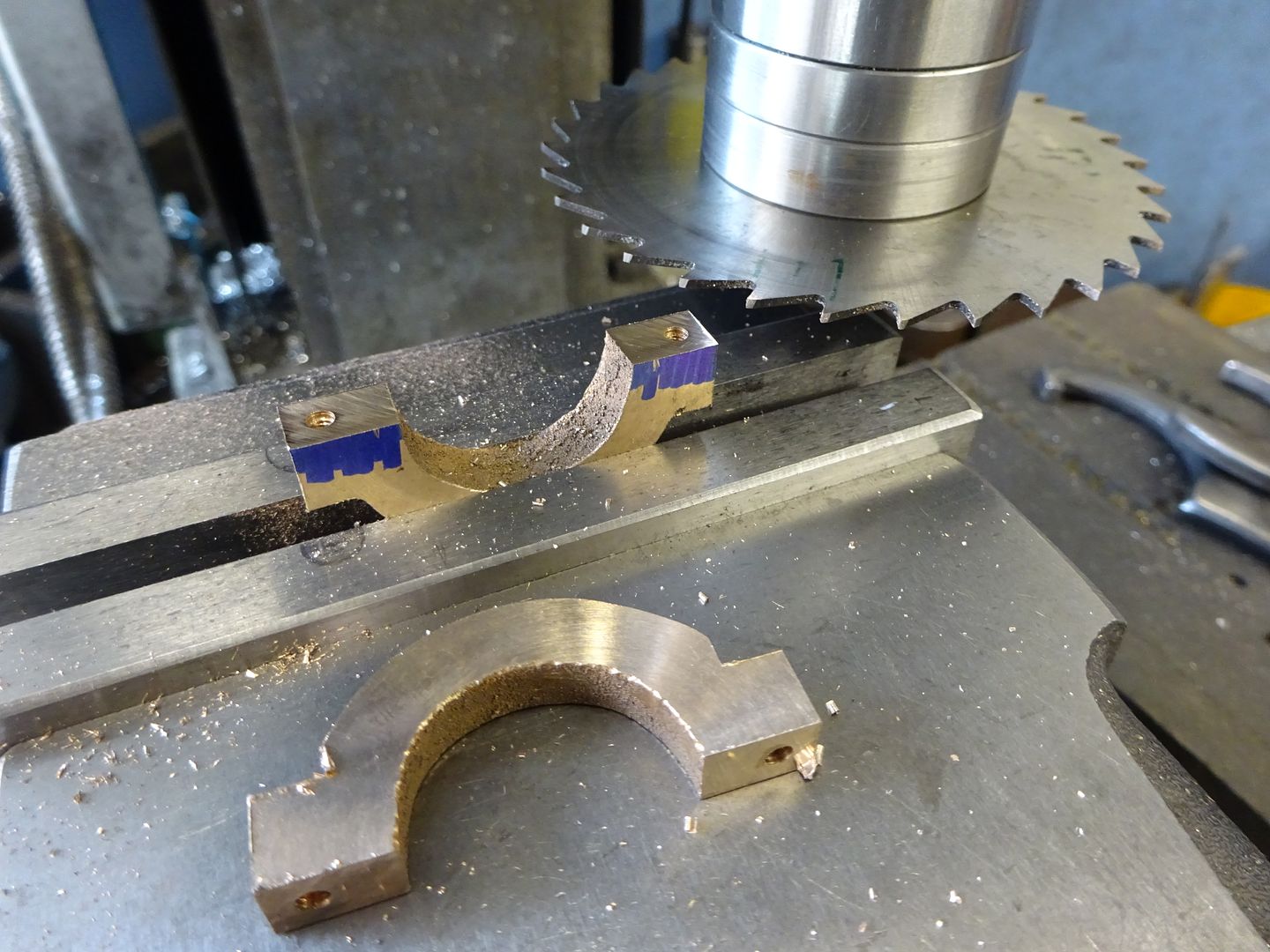

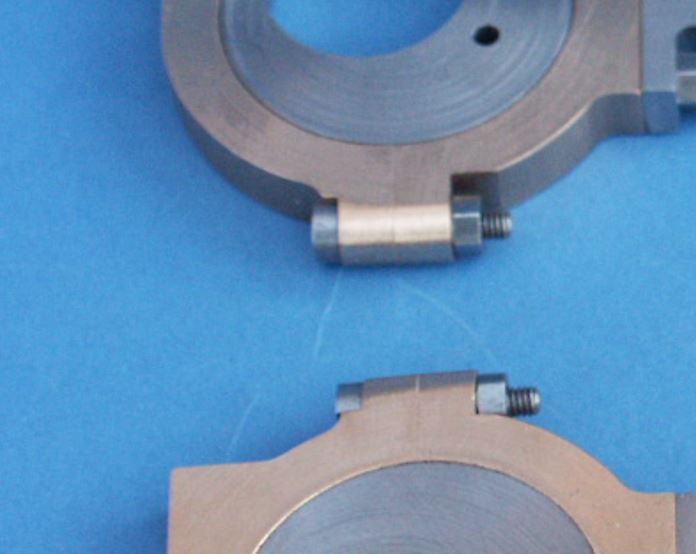

3) In the same setup, cut the straps in half with the slitting saw

4) Solder & bolt the strap halves together.

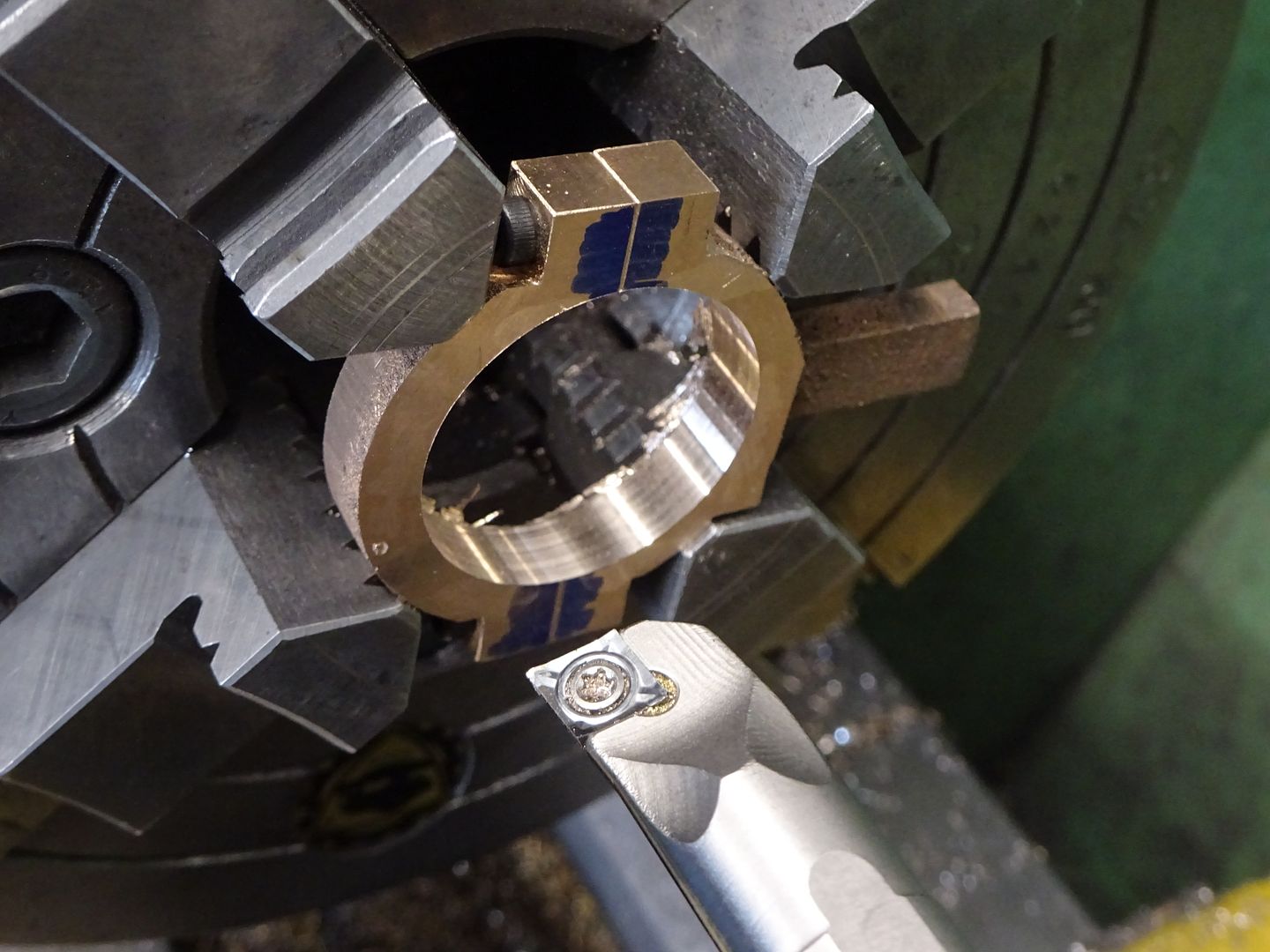

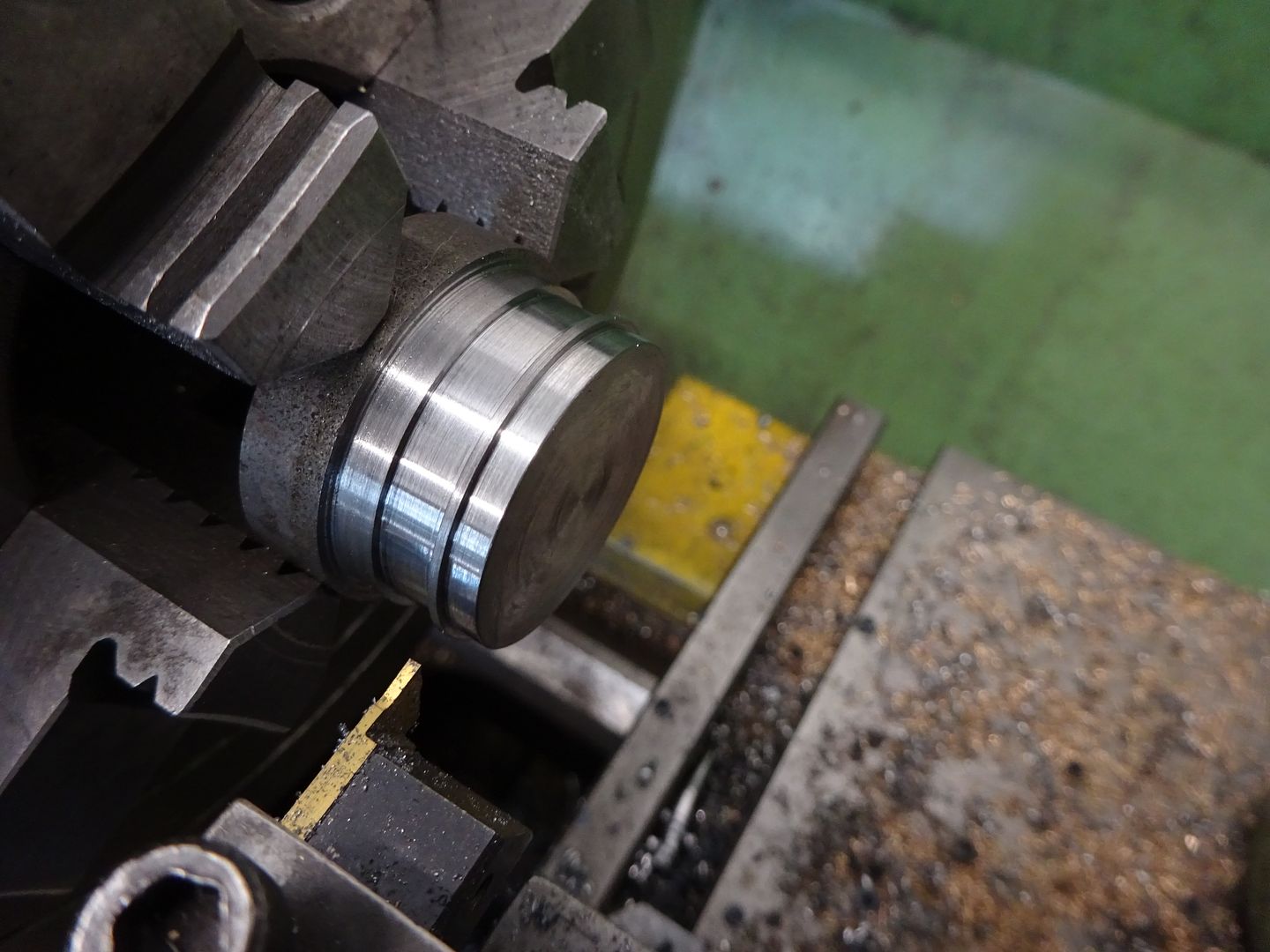

5) Make & fit a centred wooden plug, mount strap into the 4-jaw.

6) Remove plug and bore the hole.

8) Face the outside face.

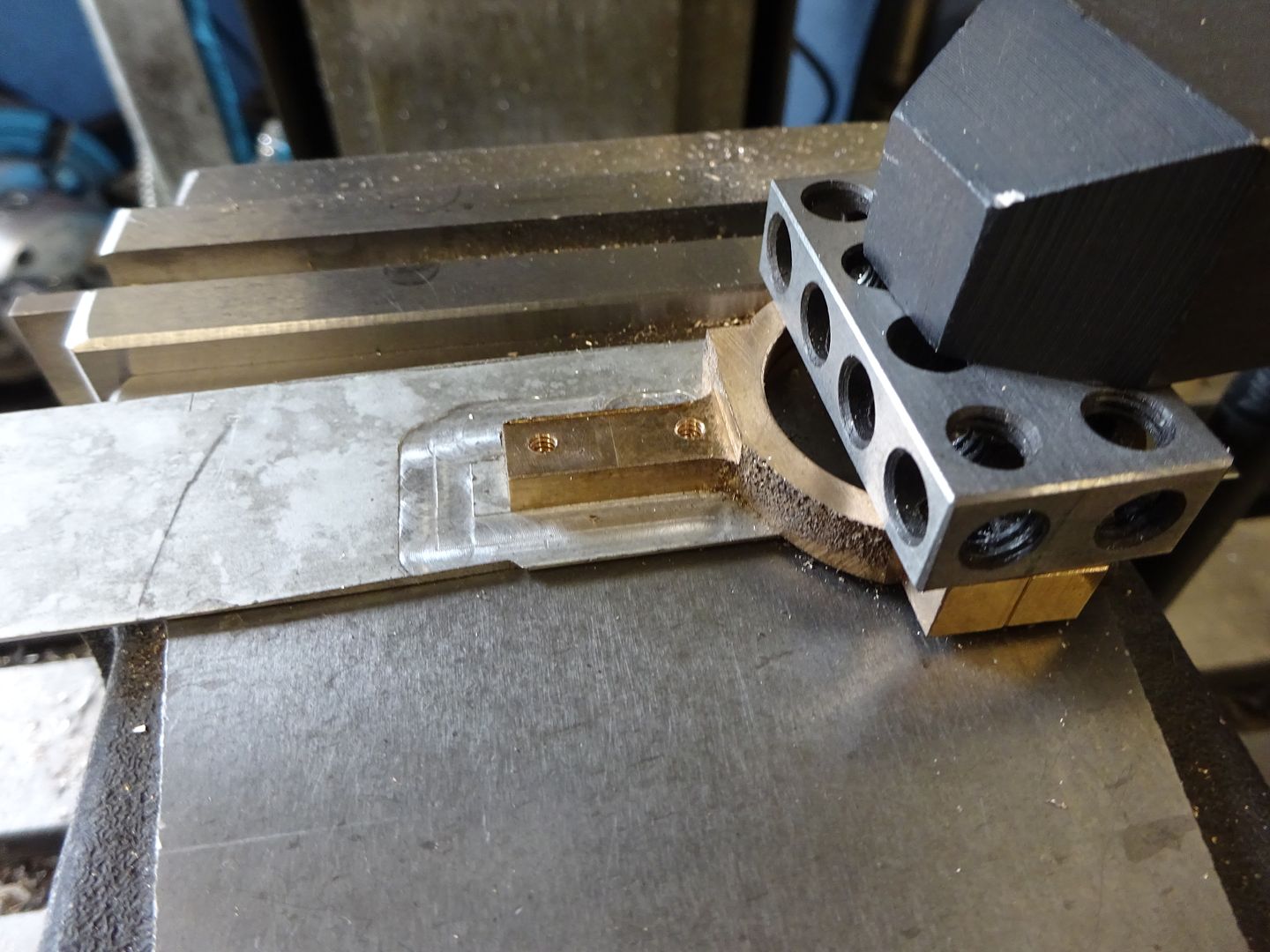

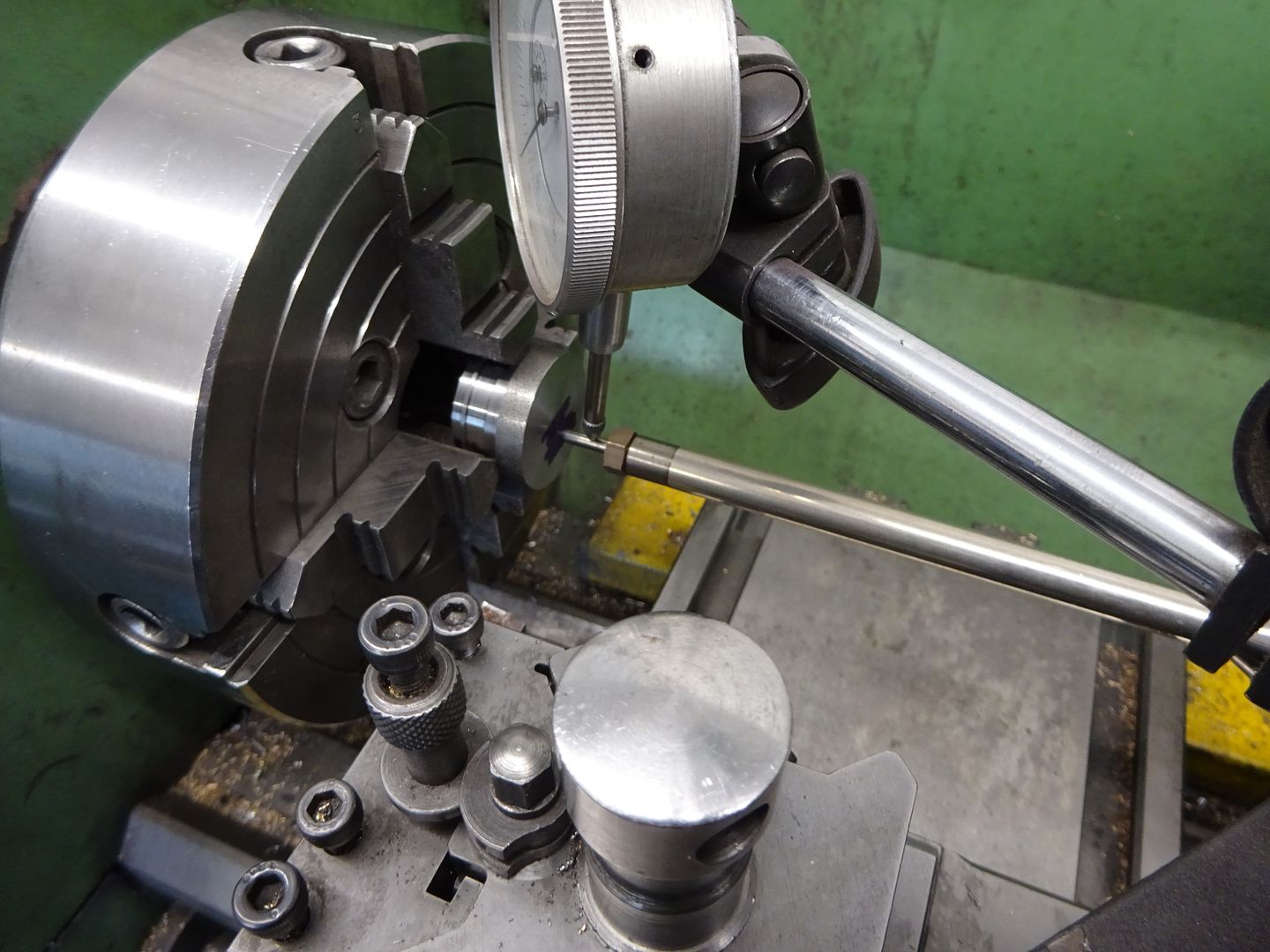

9) Make a mandrel, clamp strap around it, and face opposite side.

10) Mount in rotary table (on stub) and fully machine the outside and stub faces. Drill stub holes.

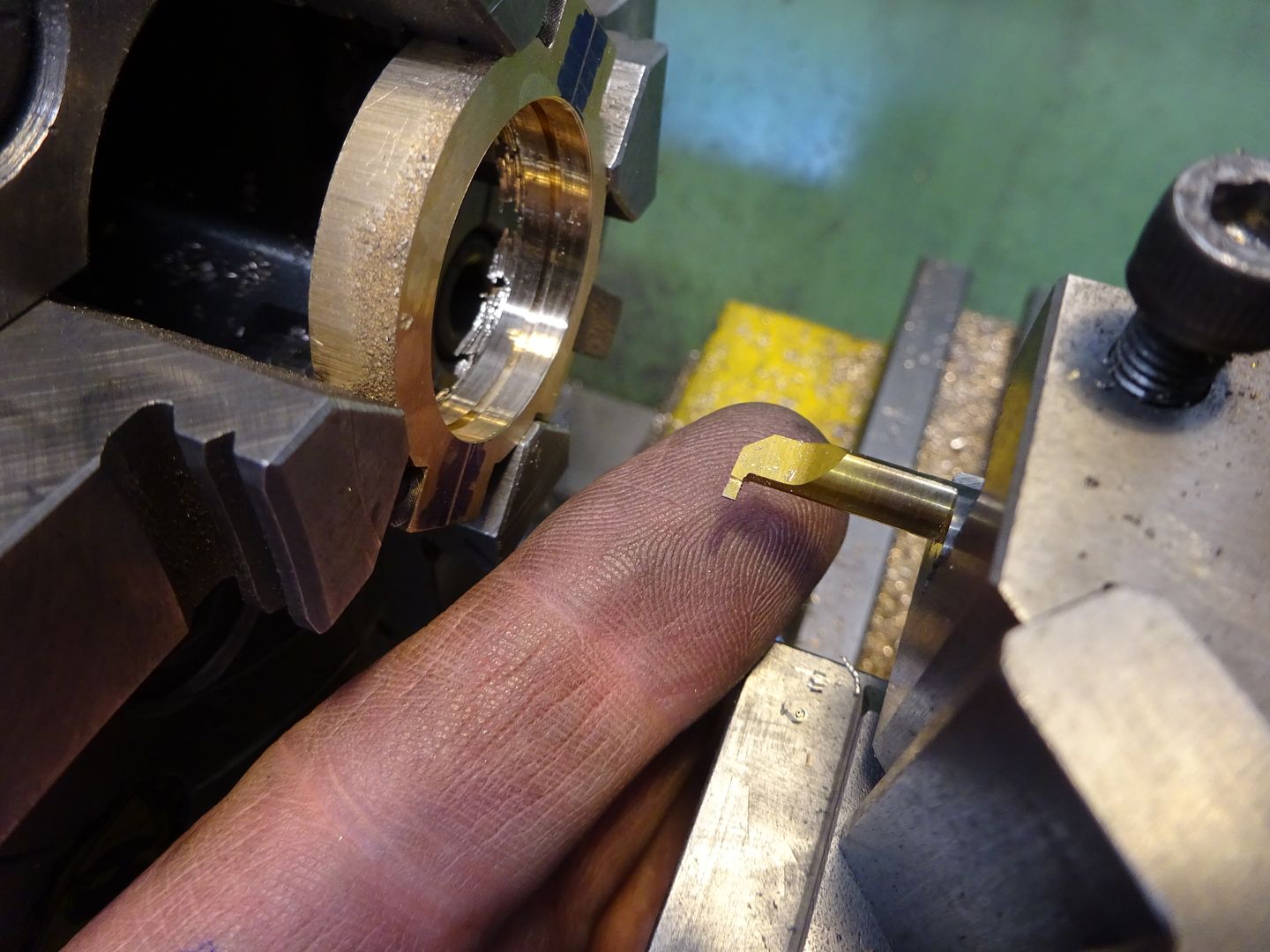

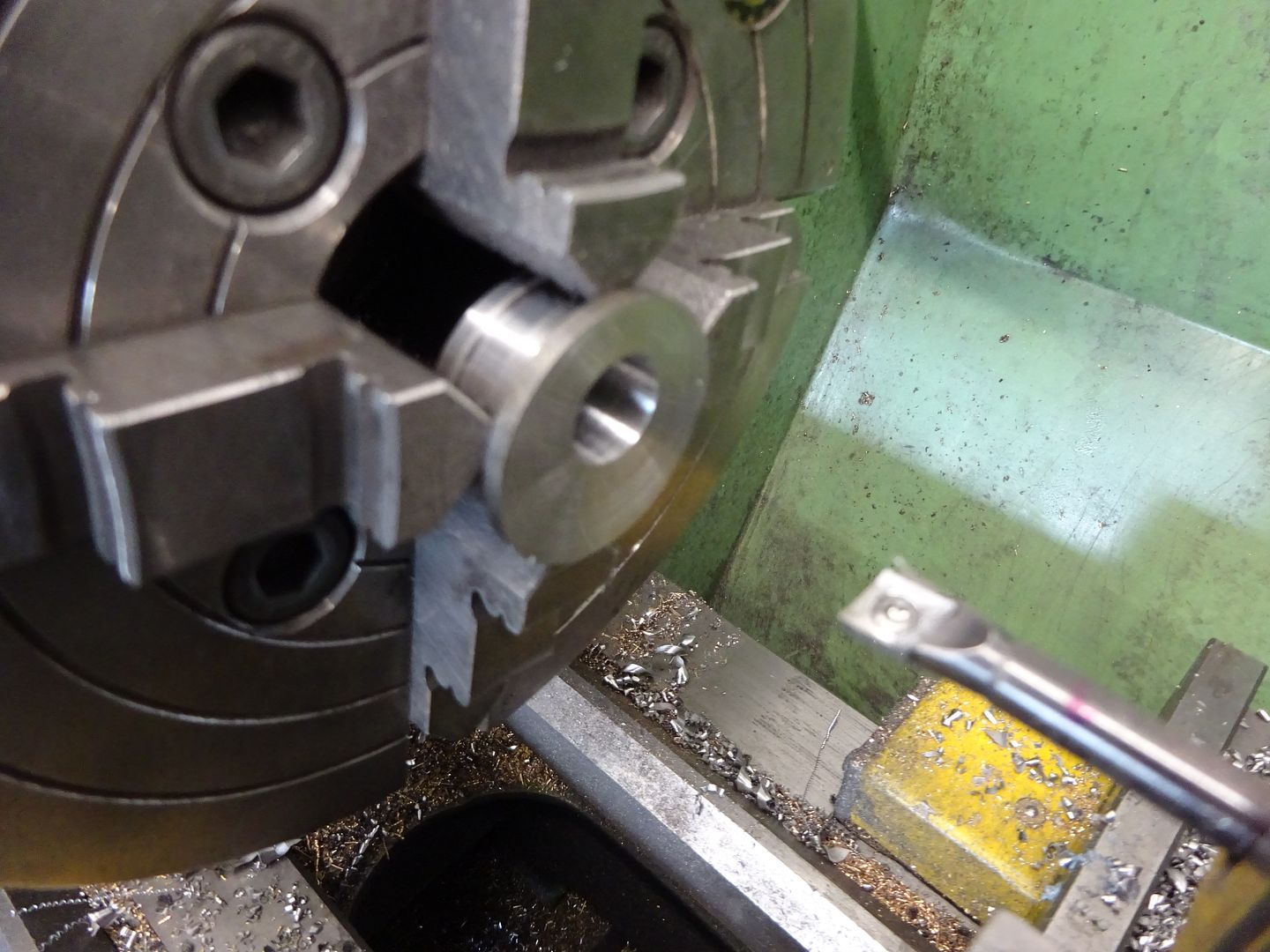

I'm unsure at what point to machine the internal groove (presumably using a modified boring bar which I know will be a challenge). I could do it after 8), but then I'm unsure how to get it perfectly central when the faces aren't to size yet.

Sheaves – No idea what the best way is, given I've got a mill, and the article description seems to be for a lathe and vertical slide – is there a better way given more equipment?

Thanks!

JasonB.

JasonB.