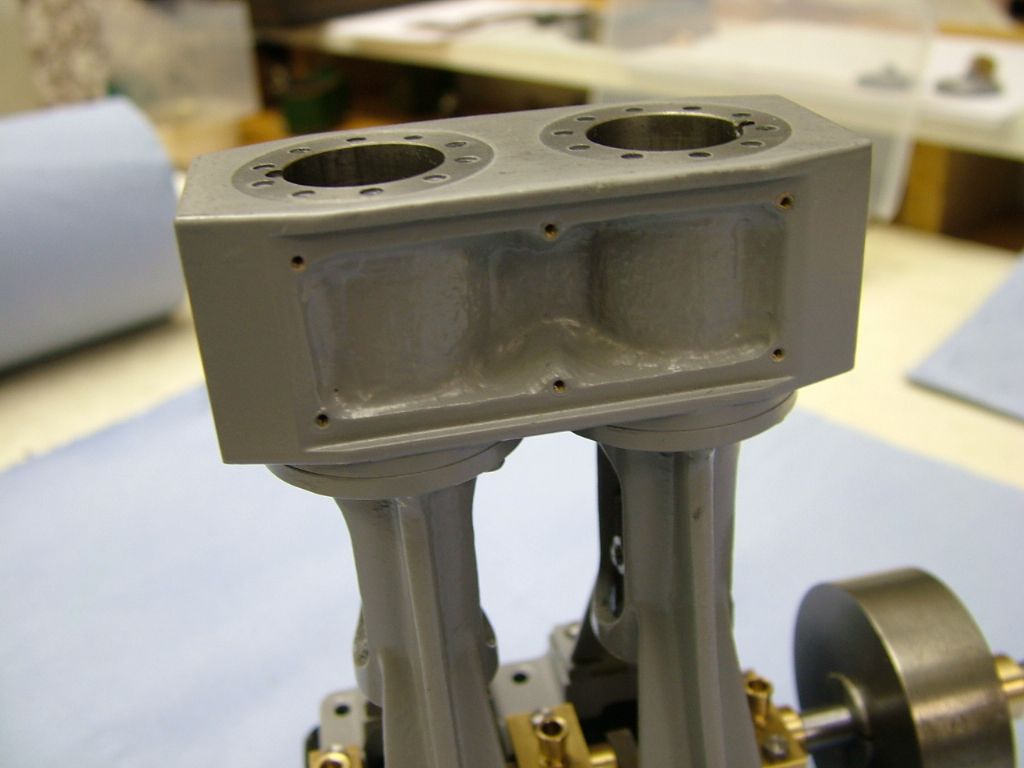

I certainly wouldn't recommend using a size for size fit and expanding the outer. If that cools before seating all the way home it will be well and truly stuck. I know a lot of wheels had tires fitted by expansion but these were craftsmen doing it day in and day out in controlled circumstances

The issue of a large diameter relevant to it's length is one of wringing – if it gets out of line it can very easily jam – sometimes solidly! Much better to do as Jason suggested and have a good loose fit – maybe 5-6 thou clearance and apply the wheel with JBWeld to give you lots of time and movement to get it right – the JBW can be used as a fillet too should you want.

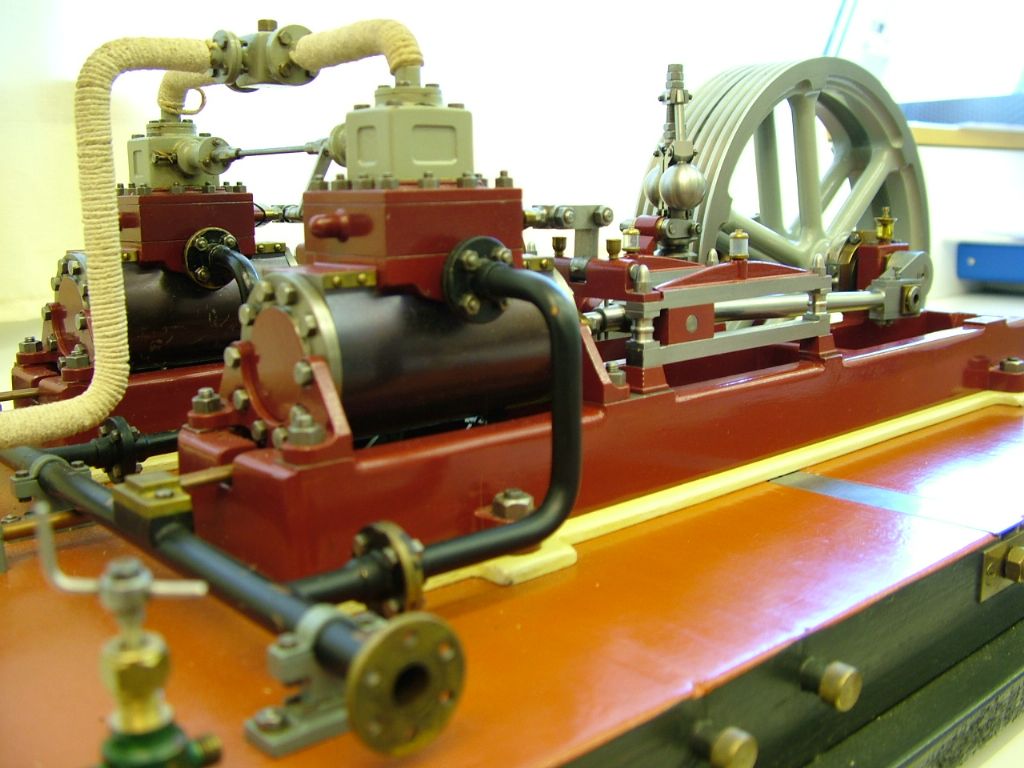

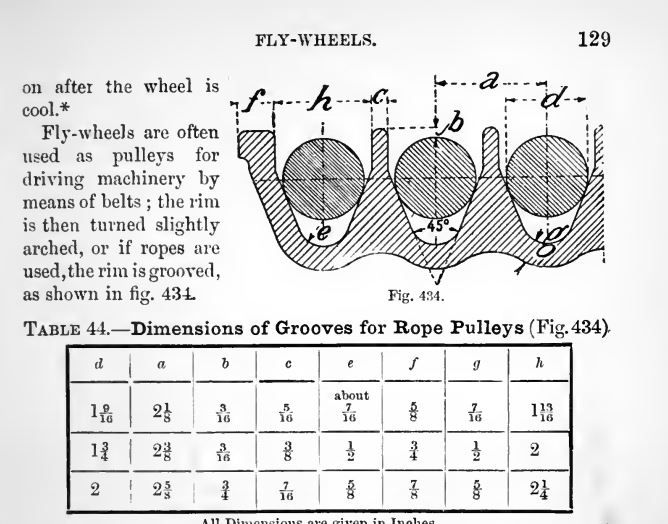

I know I mentioned it before but it's worth repeating – the only thing wrong with the flywheel as drawn is that the grooves and spacing are over scale for the type of engine you are building. It is a specific profile in real life I think it's narrower than 60 degree and has straight sides at its outer edges.

Jason, Much as I enjoy simulating metallic surfaces on plastic models I don't think I would want to use the technique on a model engineering project – some of the latest finishes are good, extremely good infact but I don't think you'd fool a model engineer with them – that is on a 'model engineering' project

JasonB.

JasonB.