Been out this morning Doc so only just caught up.

Theres nothing wrong in using a bridge clamp per se but in your set up it is the only means of holding. As you say it's on top of a make up of parallels and shims all of which provide a potential for movement. As each bolt is tensioned the forces obviously do transmit downwards through that packing but for maximum effect each would need to be equal relevant to the top surface condition. It will not take much force to bend that plate however slightly and move the pressure point to the edges. A single clamp will press through a single area to ensure a similar clamping force and an even spread of pressure to the four feet

Secondary clamping will ensure the component does not move under cutting forces unless the component is restrained by a solid surface – which yours isn't.

There may be times when a bridge clamp can be used successfully but usually on a face plate/angle plate set up where the faceplate acts as that restaining surface.

As always you pays yer money, The one thing I had instilled in my early machining career is that 'there are no shortcuts'

I can well empathise with the desire to get on with the task in hand – let's face it, that's the object of the matter but in my book your set up has a potential for disaster – is it worth that risk – not something at your stage that some extra thinking and a bit more work isn't worth doing.

I have nothing more than 6mm bolts and tee nuts and small clamps. They have done me well over many years without the need for the much larger readilly available commercial types which are far too large for small set ups.

Might it be worth making a few small clamps before moving on – you certainly have the space between the existing four bolts to add another bolt between with a single clamp and some packing on each side.

Like I said, spilt milk, once out of the bottle, isn't going to make a decent cup of tea Much better to take a step back and move forwards than have to take a step back in order to move forwards.

Much better to take a step back and move forwards than have to take a step back in order to move forwards.

All in your best interests I assure you

Regards – Ramon

JasonB.

JasonB.

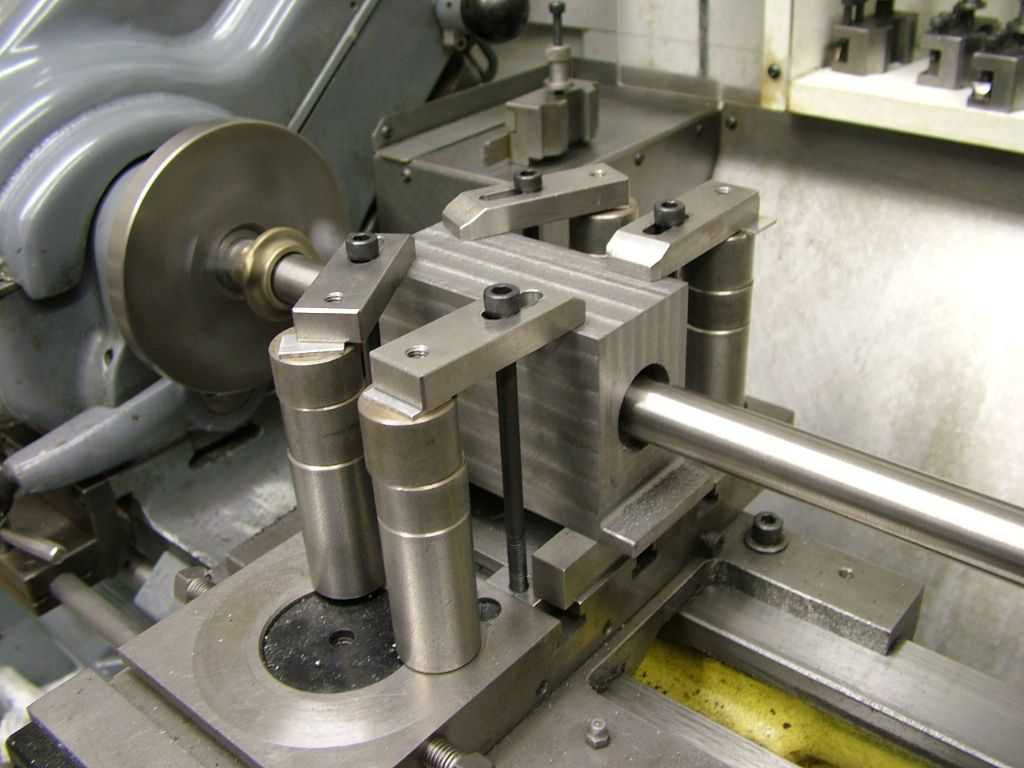

![20210727_102515[1].jpg 20210727_102515[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/897093.jpg)

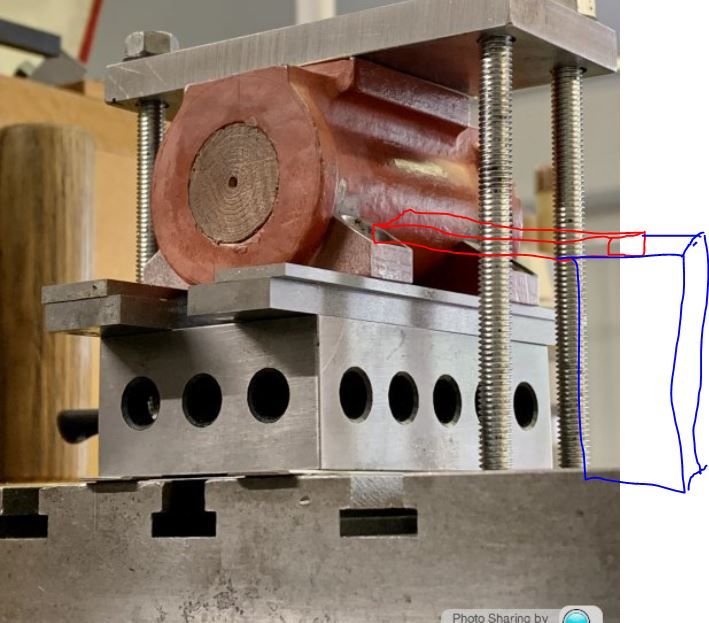

![20210727_132542[1].jpg 20210727_132542[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/897103.jpg)

![20210727_132600[1].jpg 20210727_132600[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/897104.jpg)