Posted by Michael Edwards 1 on 12/12/2019 14:03:24:

…

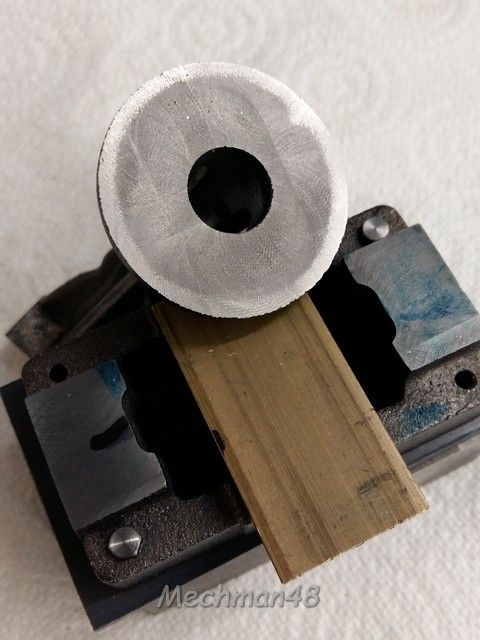

I tried not to go so cheap on these cutters but I think they were still cheap rubbish

First set were 12 different sizes for £70 (gold coloured end mills)

This new set of rippers £60 for seven (silver)

I tried a gold end mill from RDG first but that did start to rub so went straight for the ripper out of the box.

Just had an email from Stuart Models. They are sending another Steam Chest Cover out. FOC

First off, chilled cast-iron can be hard enough to give HSS a hard time. Cast-iron is on my list of difficult materials because it's anything between lovely to machine and awful. Usually the hardness is just a skin, but it can go several mm deep and a small casting might be hard throughout. As Carbide has no trouble with hard cast-iron, I always start with a carbide end-mill, only switching to HSS when through the skin.

Secondly,an important part of my learning curve was being told that tools last far longer when made to cut rather than allowed to rub. Rubbing is ruinous because it rapidly blunts the tool without removing metal. And once the edge is blunt, game over – carrying on with a blunt cutter results in poor finish, slow progress, ruined work and bad language. Rubbing is an easy trap to fall into when working with hard materials and a low powered machine. Blunt cutters due to rubbing may be the root cause behind this bad experience.

Ideally, the cutting edge should be forced deep into the material and then moved at a rate that slices steadily through the metal. Small milling machines may struggle and cause the operator to back off and blunt the tool when he should attack. After Andrew Johnson of this forum told me to stop pussy-footing, all my cutting tools suddenly stayed sharp for far longer. To avoid premature loss of edge it's also important to remove swarf and keep HSS cutters cool – flood cooling may be necessary.

Thirdly, £70 for a set of 12 end mills isn't either dirt cheap or very costly. You seem to be buying the same sort of mid-range end-mills as me, and – though I've ruined a few – mine generally give good service. I've not found it necessary to go up-market yet. Just as well, a single 20mm 4-flute end-mill from Cutwel is nearly £40 (not the dearest in the world) and expensive cutters can be blunted by rubbing too…

Glad to hear Stuart have sorted you out with a new casting. Well done them!

Dave

Lainchy.

I'm still working through mine, but getting closer to the end. I felt exactly the same though when doing the valve chest cover.

I'm still working through mine, but getting closer to the end. I felt exactly the same though when doing the valve chest cover.