Some more progress today – straightening the bore in the 'bad' bearing, desoldering and cleaning up both bearings and testing the boring bar size through both bearings in situ..

Straightening the hole in the 'bad' bearing – this went well using a 10mm slot mill, lots of cutting fluid and no problems this time.. The hole's still not quite right, very close now – but the boring bar should hopefully sort that out…

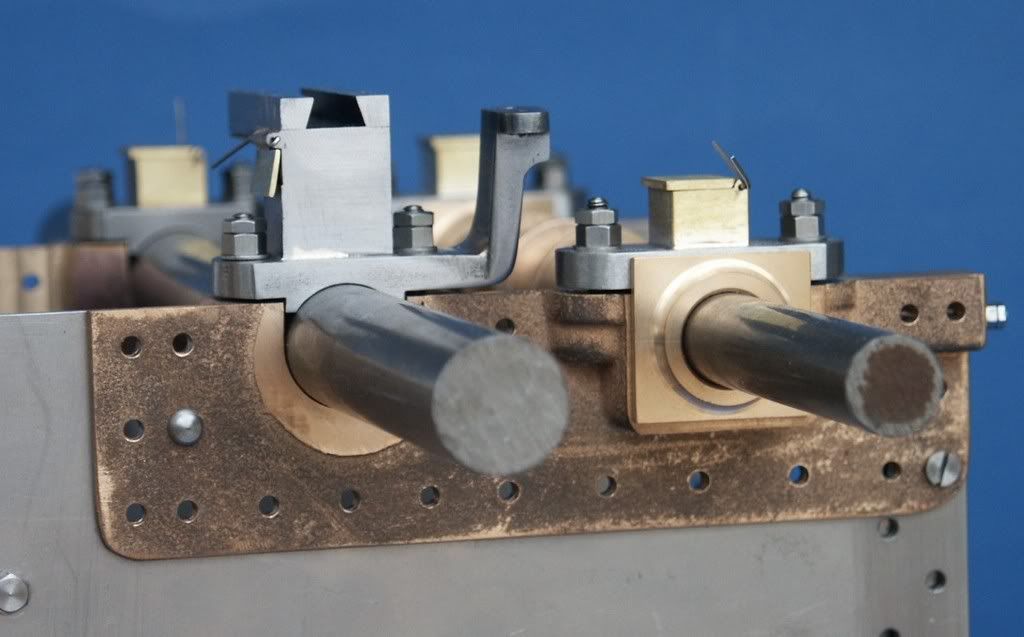

Testing the boring bar size through both bearings in situ 1.

Testing the boring bar size through both bearings in situ 2.

Ready to go onto the Lathe now.

Thinking about boring on the Lathe next and I'm afraid that I now realise that I'm unsure of the idea behind the split bearing. On Victoria the bearings were one piece and it was 'simply' a matter of boring the bearing to fit the crankshaft, or at least that's what I did. I'm assuming the idea of the split bearing is to allow the bearing to be 'adjusted / tightened down' for wear. Someone on here (this thread), sorry I must look back to see who it was, was recently explaining I think that the top bearing half is meant to tighten down on the bottom bearing half not on the bearing housing – which mine do so that's ok I hope. So I think I'm just unsure of – do I aim to make the crankshaft diameter slightly oversize to allow for such an adjustment and not slightly undersize as per the one piece bearing or should the bearing bore be exactly the same size as the crankshaft – I guess once the crankshaft goes undersize there can be no adjusting / tightening up, but that somehow does't sound quite right maybe? Hope that explains my lack of understanding..

I think I can remember someone saying when I was doing Victoria's 'one piece' bearings that they should be split afterwards – I can see that this would allow adjustment for undersize / wear adjustment as the metal removed when splitting would change the diameter allowing thus to do – hope someone can see why I'm unsure of what to aim at….

If anyone can explain I would be grateful.. At the end of the day I may not be able to work to the tolerances needed anyway but nevertheless it would be good to understand the concept, and especially for when using better equipment in the future…

Regards

Allan.

Neil Wyatt.

Neil Wyatt.