A couple of points about setting teh tool.

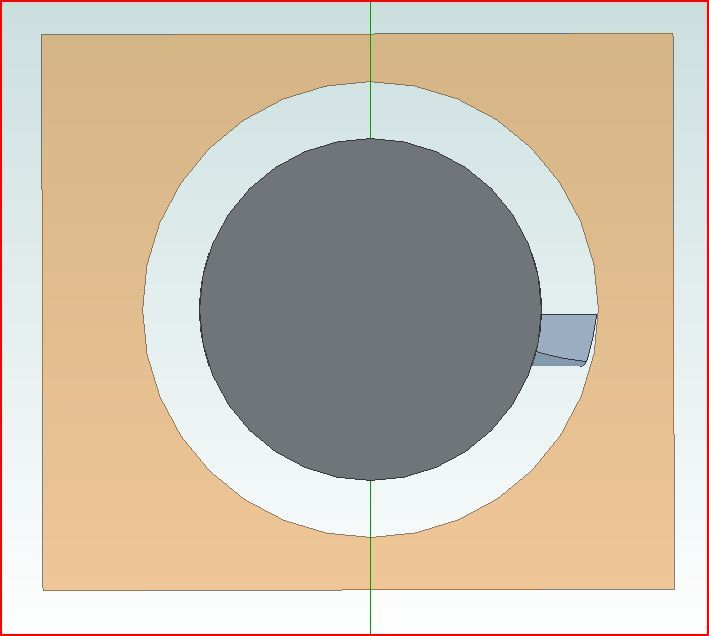

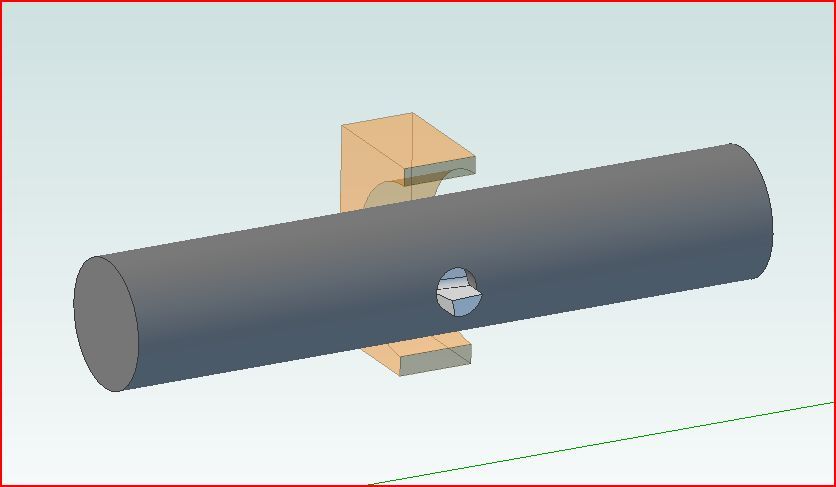

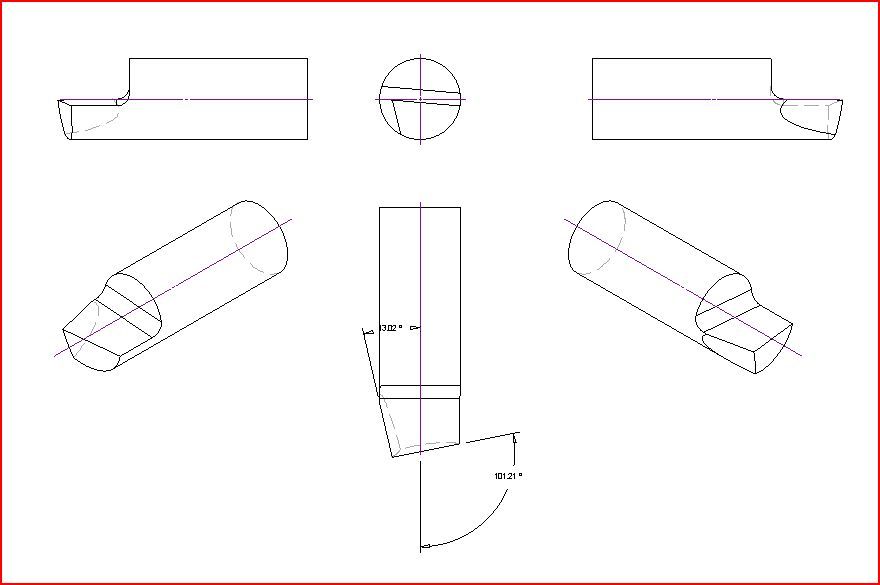

I theory with a 3/8" bar and the tool sticking out 1/16" it will measure 0.4375 on the mic and produce a 1/2" hole.

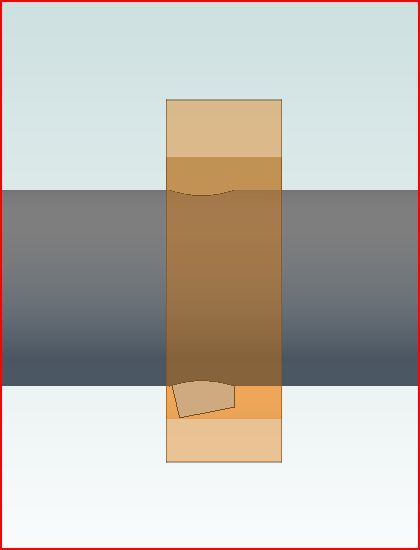

In practice the tip may not be exactly on the central axis, the bar may be running a fraction eccentric or have a slight bend/bow making it cut over or under the calculated size.

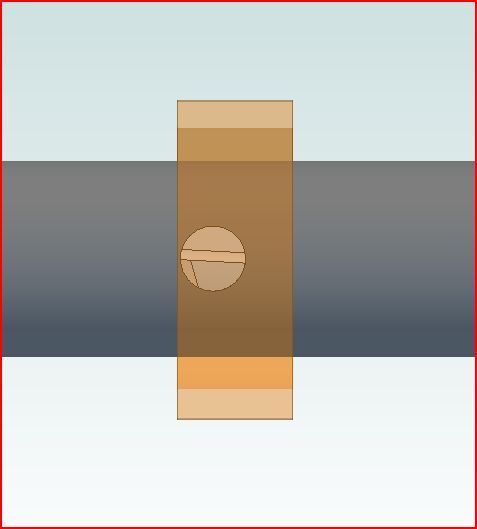

So take some measurements of the bore you are produceing and work out how much more the tool needs to be advanced to arrive at the desired size. Its not easy measuring a small bore so find something a bit smaller than 1/2" either the shank of a 12mm cutter or a 15/32" drill and use that as a bore gauge. A bit of maths will then tell you how much to advance the too to get to teh crankshaft size but when you get close do test fit rather than just measure.

On way to set the tool to a measurement is to have the grub screw just making the bit firm, push it out past where you want and then use the mic to gently squeeze it back into the bar, stopping when teh mic reads what you want the tool set at.

J

Neil Wyatt.

Neil Wyatt.