My bearings turning into a bit of a saga I think. Hope not everyone has given up on me yet though and some still finding it as interesting as I do…

This morning I made a start on the bore for the second bearing, intending to go to 10mm (not 8mm as previously said) ready to go on the lathe… After putting a 10mm Slot mill through the 'bad' bearing to sort out the wonky hole they should then be pretty close for further work..

The first slot mill about to be put through – 8mm

All going well with the slot mill, nice and smooth, no 'grabbing' of the work then progress stopped. I couldn't understand it for a while – then I realised that the Slot Mill had a 'shoulder' on it and I had reached it's maximum depth. None of my other Slot Mills have a shoulder – just this one! Unlucky again or just stupid for not noticing – don't answer that! Anyway my next Slot Mill size is 10mm (no shoulder) so off I go with that one, and again all going well until i come to the bottom of the hole and about to break through. As I hadn't reached the bottom with the last Mill it was now asking too much of the Mill and it stopped dead – and would not restart. I was glad I had used all the clamps and 'cradle' or I'm sure I would be redoing the bearing at this point otherwise… In all the work I have done with the mill to date I have never even seen it slow down let alone stop dead. I feel justified and glad of being so wary of the Gunmetal now and in taking all the precautions. Its tricky stuff if not used to it I think – drilling steel is a doddle by comparison!

Photo of the 8mm Slot Mill with the shoulder – and another, as per all my others, with no shoulder. I'll be checking for this sort of thing in future!

Luckily its just a blown fuse. The one blown is 6A, the Mill came with two spare fuses both 10A. Fitted one of those, best get another 6A to go back in I think. The Mill was fine again then.

The end results though are not too bad. This is one side of the 'second' bearing at 10mm bore. Needs cleaning up lots more, but has yet to be de-soldered again of course so I haven't been too fussy yet…

The end results though are not too bad. This is one side of the 'second' bearing at 10mm bore. Needs cleaning up lots more, but has yet to be de-soldered again of course so I haven't been too fussy yet…

This side 2 of the 'second' bearing. Not quite aligned. Will definitely be trying Loctite next time for this kind of thing which should be much cleaner and hopefully much easier to align properly…

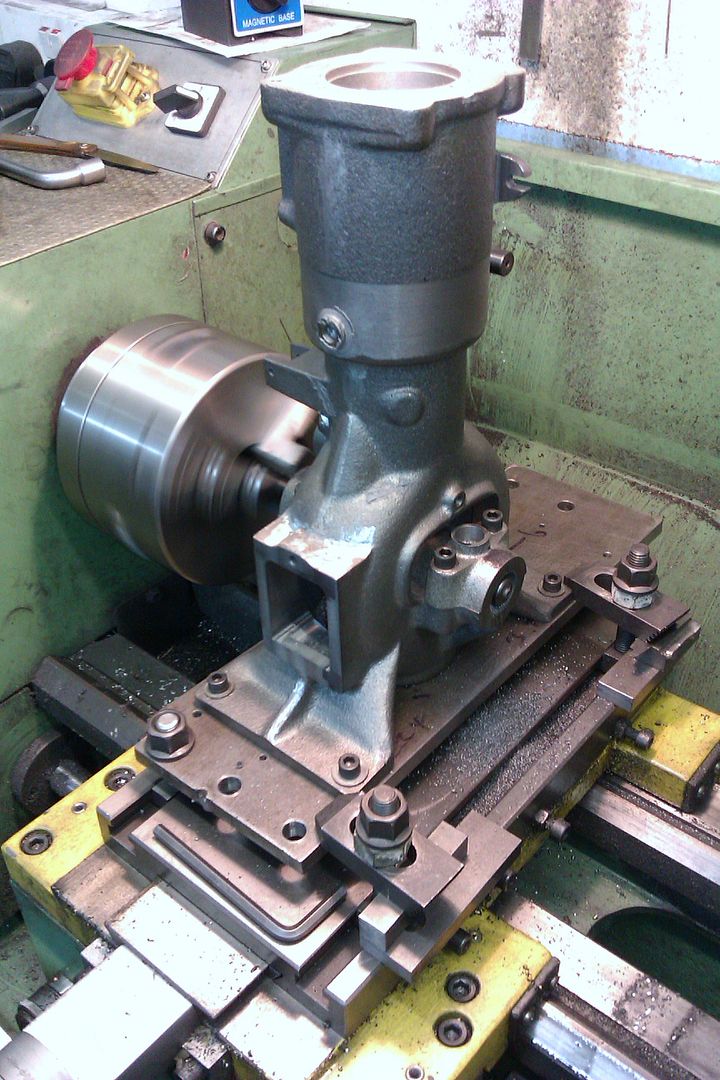

Test fitting the 'second' bearing in its housing. The alignment not too bad.

Next to drill and tap the stud holes for fixing and then onto the Lathe…

Regards

Allan.

Neil Wyatt.

Neil Wyatt.