Hi all,

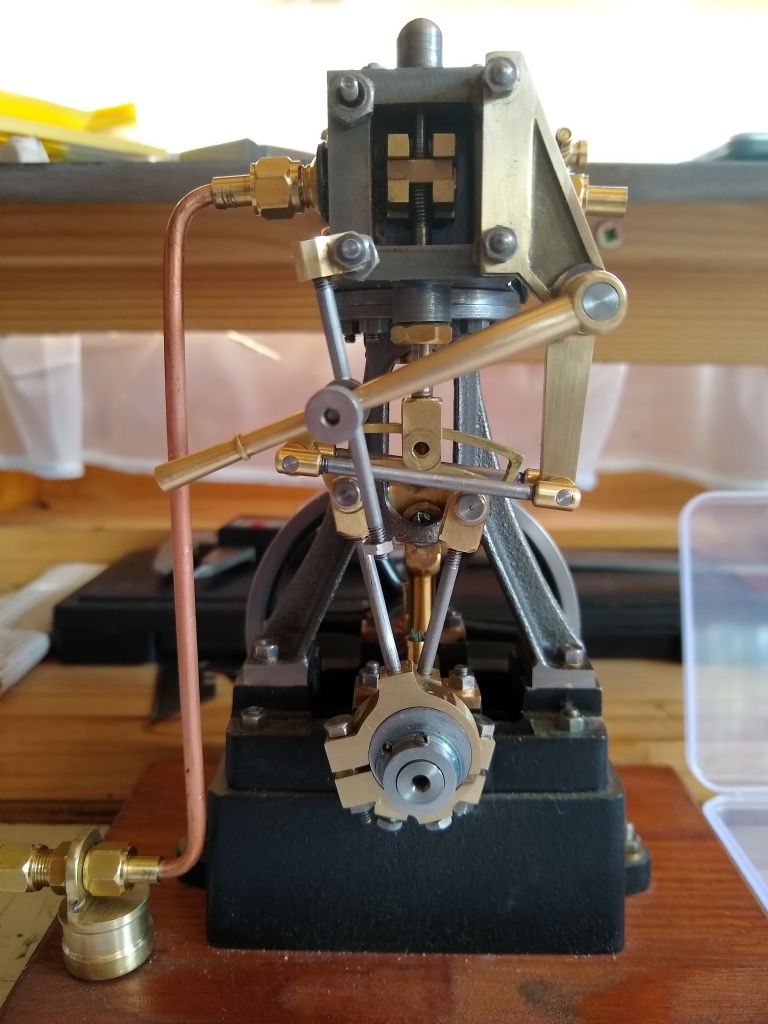

I'm adding the Reversing Gear to my Stuart 10V.

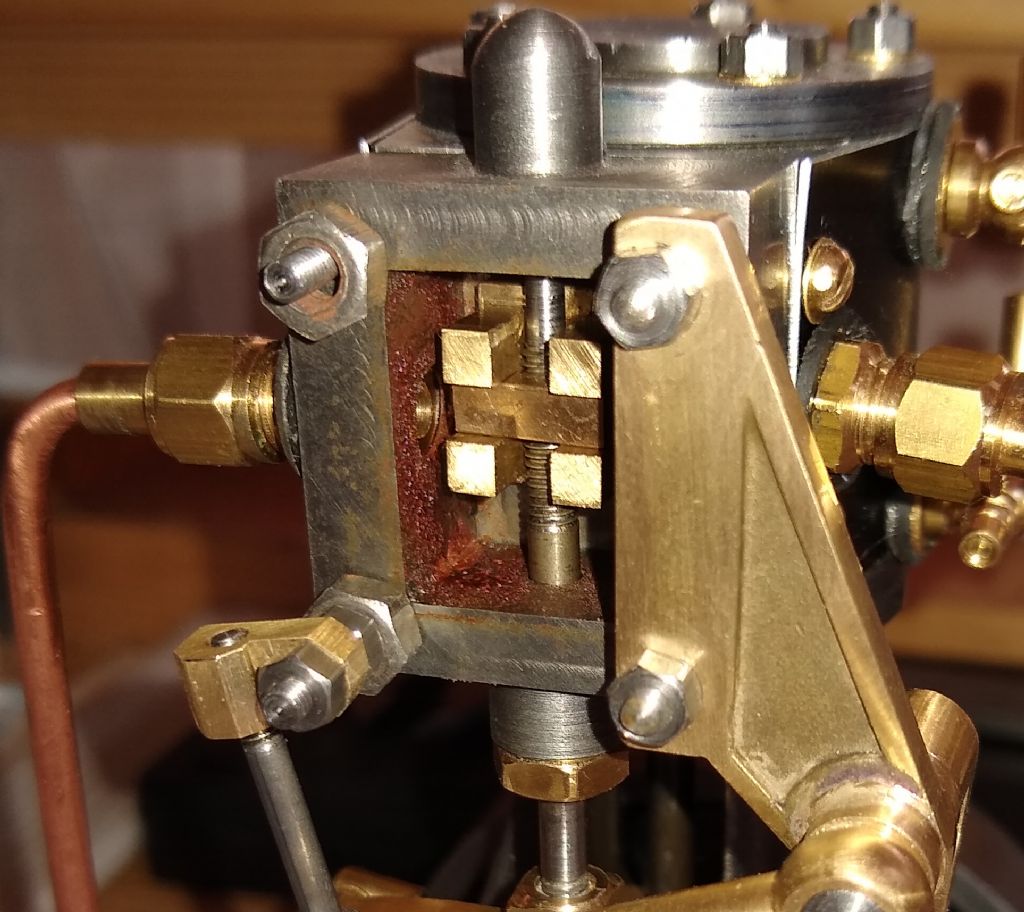

Upon removing the valve chest cover I noticed there is rust towards the Inlet side of the chest.

I have been adding light oil to all moving surfaces, so was surprised to find the rust. The 10V has spent most of its life indoors with perhaps 10% of it's life in the garden shed. It is powered by a Hyundai air compressor.

I has now dawned on me that I should have occasionally been unscrewing the Inlet connection and adding oil into the valve chest.

I imagine the moisture is arriving via the compressed air and condenses on the cold mild steel valve chest.

I can remove the rust, but wonder if there is better way of adding oil, than unscrewing the Inlet? eg a little brass fitting that screws in to the top of the valve chest and dispenses a tiny drop of oil every few minutes (when the 10V is functioning). It would somehow have to keep the pressure seal intact.

I have had a quick Google and search of the Forum but nothing pops up.

Any advice regarding a possible oil gladly welcomed.

Regards,

Ches

Addendum: I've just spotted some 10Vs on Google images with a small, upright cylinder fitted upstream of the Inlet …hmm…and Stuart models sell such a thing ( https://www.stuartmodels.com/product/displacement-lubricators/ – Displacement Lubricator, which I now remember reading about months ago). But it's £50 (less VAT) which is about half the cost of the 10V casting kit…double hmm.

Any thoughts/advice still welcome

Ches Green UK.