Hi All,

I am including today a photograph of the standard and the cylinder to highlight the issues I have to deal with in these two parts.

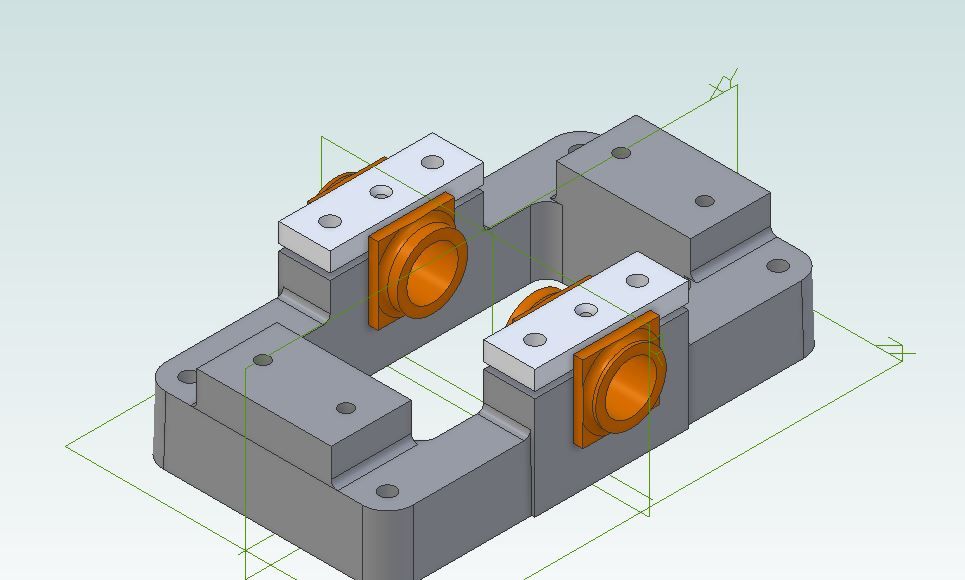

The Standard

1 The bore of the standard should be 16mm or 5/8" it also should have 4 holes on a PCD of 28mm 1-1/8" I have 5 slots to deal with on this standard.

The height of the standard is 70mm 2.763" so I have some metal I can remove as the drawing standard height I understand is 68mm 2-11/16"

For the bore I am not sure what approach I should take as there is not a lot of wall thickness to enlarge the bore, I could true it up on the lathe and just ensure it is round and clean it up a little, not the ideal solution.

For the flange, I will either have to plug up the slots or I am thinking to machine remove the flange and turning a spigot with a shoulder to receive a new flange, the new flange could be silver soldered to the standard and then machined to the final size.

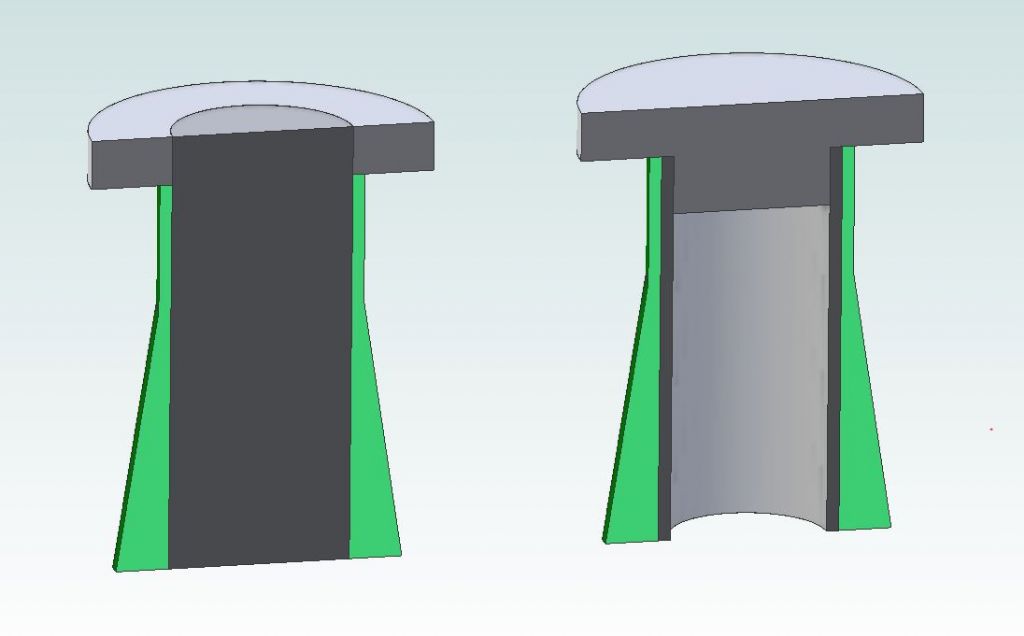

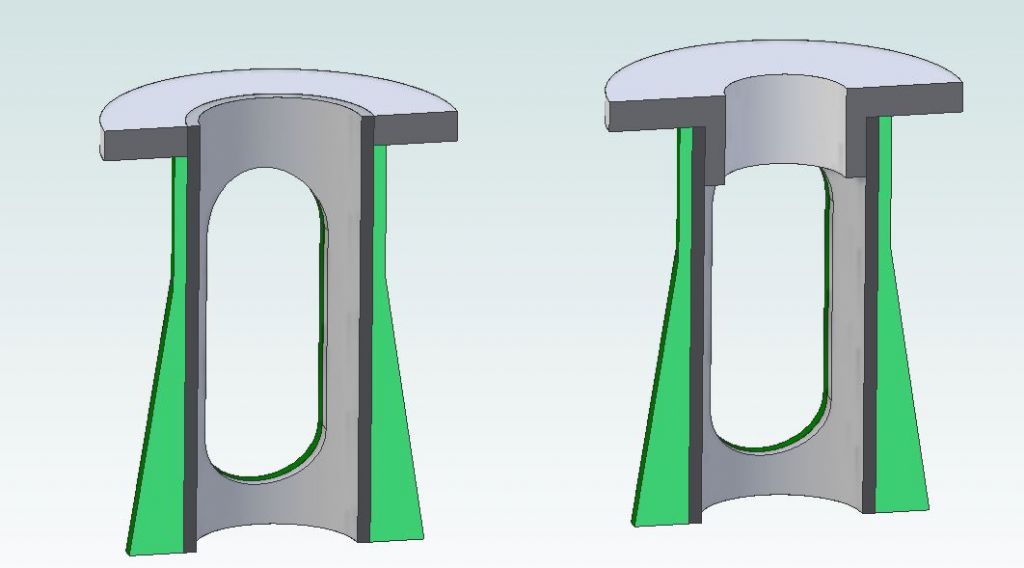

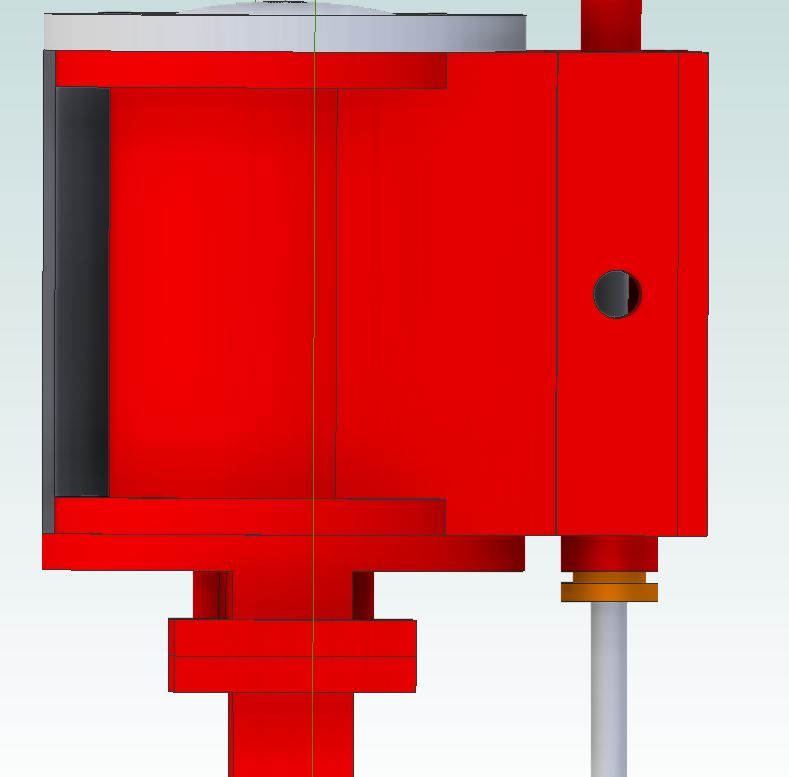

The Cylinder

As you can see the cylinder needs some love and care to restore it to what it should be.

The bore has a brass sleeve with a bore of 18.59mm .731" it must have been machined oversize when it was made looks like it could have been 21.35mm .840" before sleeving, wouldn't mind some suggestions on this one.

The length of the cylinder is 30.60mm 1.204" this should be 28.5mm 1/1/8" so I can remove metal from both faces to ensure that both faces are parallel and to the correct size.

For the holes in the cylinder, the best approach would be to mark them up and see if any of the holes are in the correct position the remainder is to be plugged using a threaded rod and the holes are redrilled in the correct positions.

For both these faces due to the current positioning of the holes, I do not see many where the holes will be converging with the newly positioned holes.

For the future i will improove the quality of the pictures.

Edited By Jim K on 13/10/2022 04:25:10

JasonB.

JasonB.

,I believe this should not make a difference as long as the measurements for the bearing holes are as per the drawing.

,I believe this should not make a difference as long as the measurements for the bearing holes are as per the drawing.