Thanks Jason. Unfortunately (and somewhat inevitably) this is where it all goes wrong…

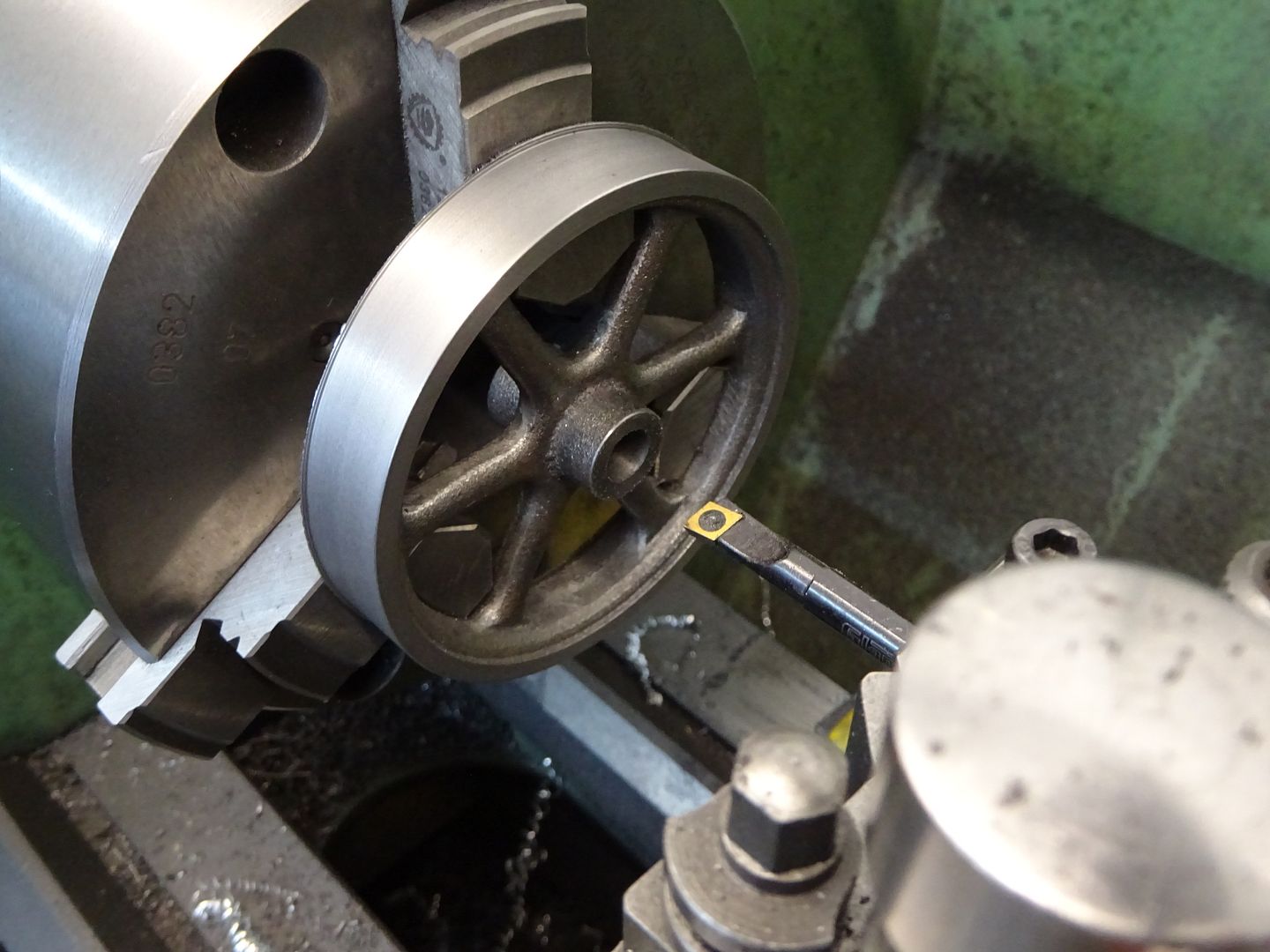

The valve rod is stepped, and threaded. First of all I made a split bush to fit the 3-jaw chuck (4-jaw won’t close enough). I got it to within 0.0015” of true, centre drilled and turned the end to be a good fit in the valve chest top as per the image:

Not sure if this was the best method, but I didn’t get a particularly good finish on the end. Still, it fitted smoothly enough.

Then, the 5BA thread. The die wouldn’t go on the turned-down end. This is where my heart sank as I realised what I’d done. The hole in the top of the valve chest should be 3/32” (2.38mm), but for some reason I’d ended up with 2.75mm.

The root diameter of the 5BA tap is 2.49mm. so obviously it won’t go on.

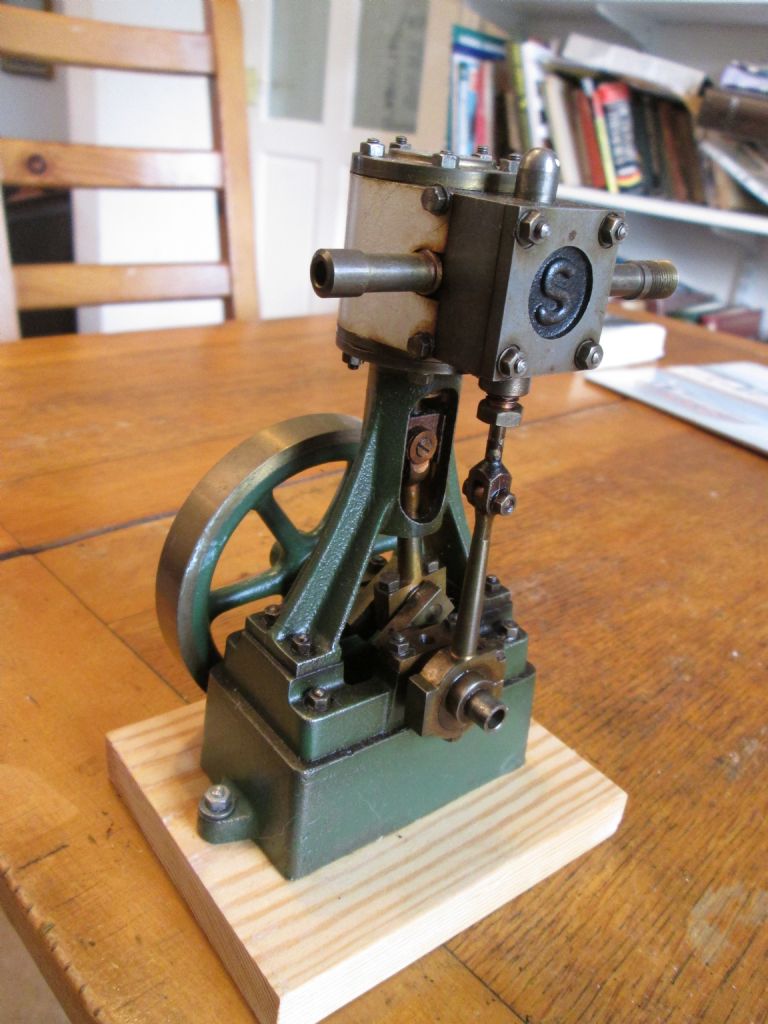

M3 has a root diameter of 2.46mm (too small) and a slightly finer pitch Than 5BA. I had an old M3 die which did, for whatever reason, fit over the spigot, but the thread was all over the place. A new M3 die wouldn’t fit at all. The rod also got slightly bent during all this. It does fit, and it does slide in the chest, but it’s not right at all – too sloppy, and the end got damaged by the die:

So…I don’t want to re-make another valve chest because it fits everything else perfectly. The only option I can see is to drill the top chest hole out to 1/8” (same as the reamed gland hole at the bottom), Loctite a brass plug into it and re-drill to 3/32”. That would effectively leave me with a 0.4mm wall thickness sleeve in the top end.

And of course I'd re-make the rod from scratch.

I could do with some advice on turning small diameter rods in silver steel/stainless. I've never been able to do it properly. In this case, I had to leave enough protruding from the chuck so I could remove the tail centre and keep test fitting it in the valve block, which is relatively deep. I'll need to nail a technicque for doing them for other critical parts that are on the horizon.

If I do have to buy another valve chest casting and start again, I will do, but I'd really, really prefer not to.

Thanks!

Dr_GMJN.