Moved on to the standard – I’ll do all the base drilling at the same time.

First job- clean up the castings with files:

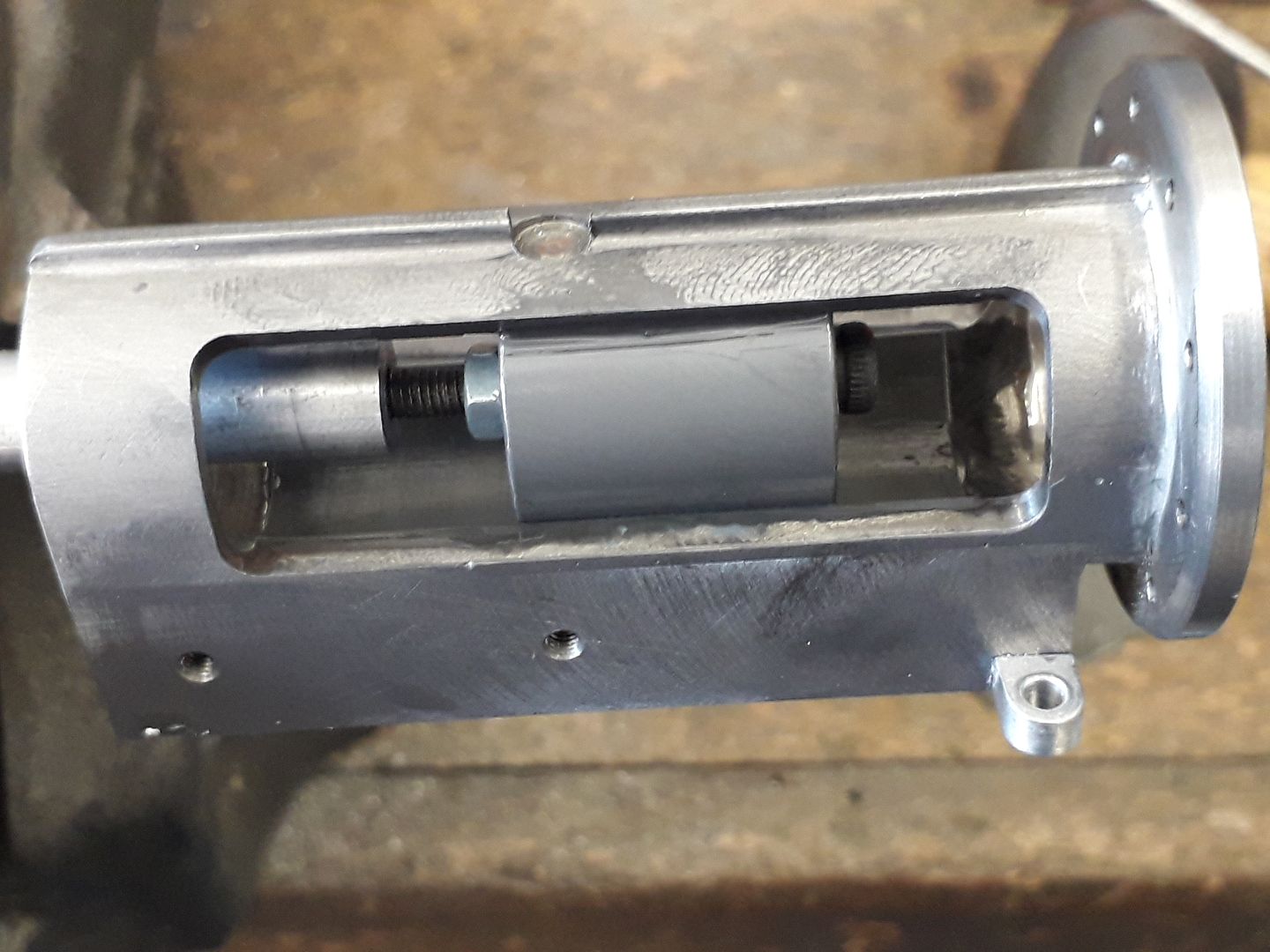

I made a mandrel from a cut down bolt, cross-drilled for a drive screw:

I wrapped some shim steel just to take up the bit of play, and copper washers to protect the collet and casting:

I should have let the bolt protrude more so I had room for a tail support, but in practice it machined easily:

I might have to machine some more off the feet, because when I marked the specified height with a scriber, it seemed too far down the upper flange. If I machine down to that, getting the thickness right won’t be possible:

Then again by the time I’m done cleaning the top face up, getting the specified thickness will be very close I think. I’m wondering whether to just leave the feet, clean up the underside of the flange and see where I am. Maybe live with the overall height being a millimetre or so too much. Not sure – seems like a bit of a bodge.

Question about the machined bore for the slider – and for the main cylinder for that matter: I'm thinking to machine them to a 'close enough' dimension to the drawing, concentrating on surface finish rather than absolute accuracy, and then make the piston/slider to suit whatever bore diameter I end up with. I could machine small amounts off the piston/slider until I get a good fit – checking by repeatedly machining and test fitting in the bored parts. Is this OK or totally bad practice? I doubt I could machine the parts in isolation to a dimension and get them to fit, so I don't think I've got much choice. There are no tolerances on the drawings anyway, and even it there were, I doubt I could hit them!

Thanks.

Dr_GMJN.