Hi There

Welcome to the build thread for a Stuart 10H and 10V. This thread is all about how to build the two engines using a small home workshop.

I have a Warco WM180 lathe and a Warco WM14 milling machine. Also available are a Warco bandsaw, a Clarke variable speed pillar drill, a bench grinder, a Clarke vertical linisher/ disc sander, a power scroll saw, an engraving machine and an Oldak production tapper.

The engines will be made using the Warco lathe and mill and the vertical drilling machine. Photos of the machines will be added as we go through the series.

You may comment as you wish, I have a thick skin having been editor of both ME and MEW for many years.

You are welome to copy the posts and photos for personal use only.

The 10V casting set is on the left and the 10H set is on the right.

First I have to clean off any flash and remove the casting feeds on both engine bases and bedplates.

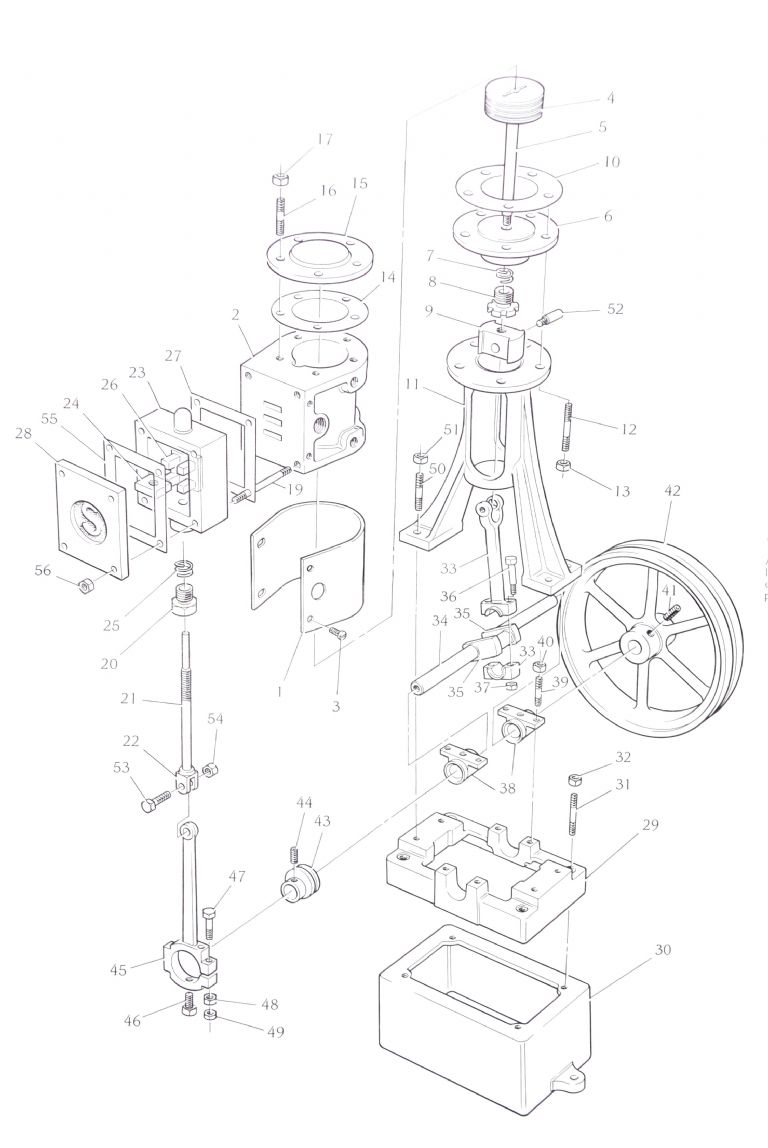

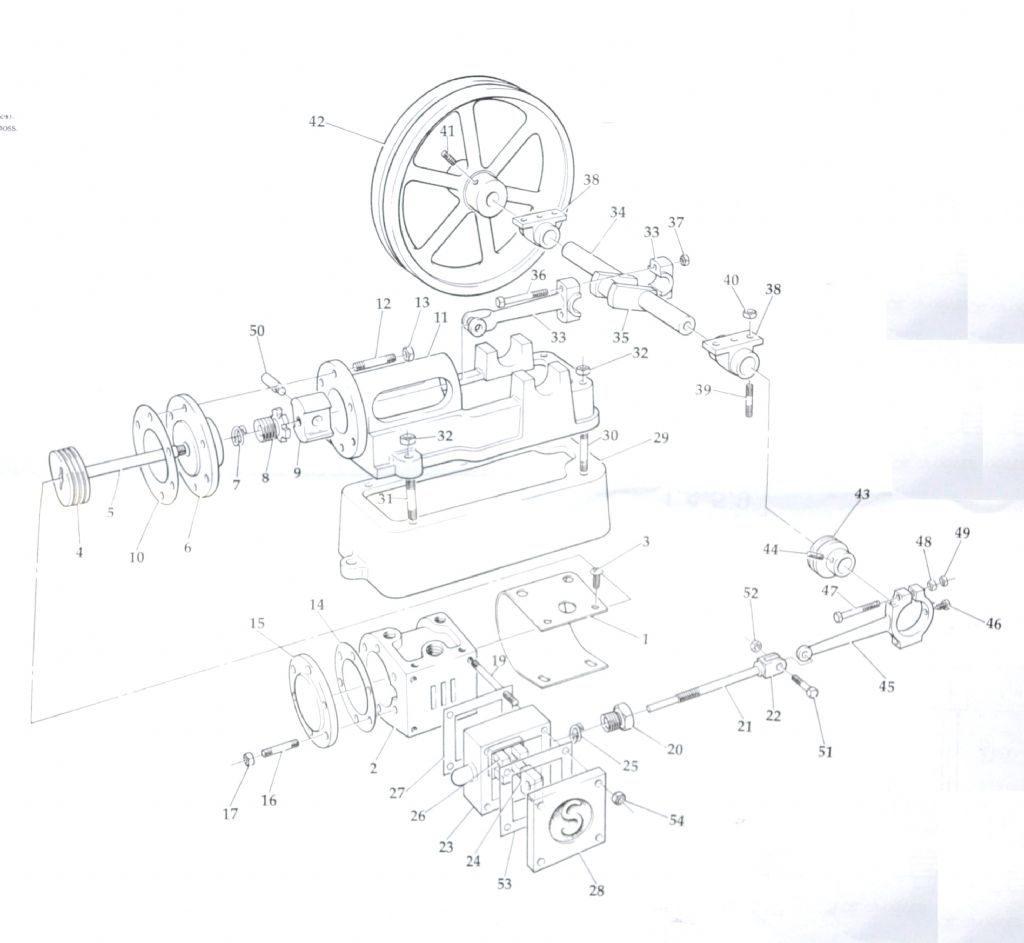

Andy at Stuart Models has kindly given me permission to include copies of the 3D exploded diagrams of both the 10V and 10H engines.

I have no connection with Stuart Models other than being a satisfied user.

STUART MODELS

Grove Works

West Road

Bridport

Dorset

DT6 5JT

Tel: 01308 456 859

Fax: 01308 458 295

Email sales (at) stuartmodels.co.uk

Exploded 3D view of 10V vertical engine above.

Exploded 3D view of 10H horizontal engine above.

If you click on the drawings they should enlarge to enable easy reading.

I will use Stuart's part numbers if I need to refer to parts..

Edited By JasonB on 17/11/2015 19:24:46

Nicholas Farr.

Nicholas Farr.