EWers and bookmarkers,

One of the limitations that I found with the EW when I got my first one decades ago, was the difficulty in having a graduated ring at the leadscrew handle. The problem is that the leadscrew position is very close to the top of the bed. To be precise, a nominal dimension of one inch from the top of the bed to the centreline of the leadscrew. The dimension from the CL of the leadscrew to the top of the rear leadscrew trunnion is nominally 7/16" so that the graduated ring could only be a max of 15/16"dia. Quite useless! Any more and the tailstock would not be able to be removed

I scratched my head looking for a simple solution to this problem and looked at making a removable handle that could be much bigger but remembered that I quite often used to have the tailstock pushed back over the end of the bed whilst doing a bit of milling.

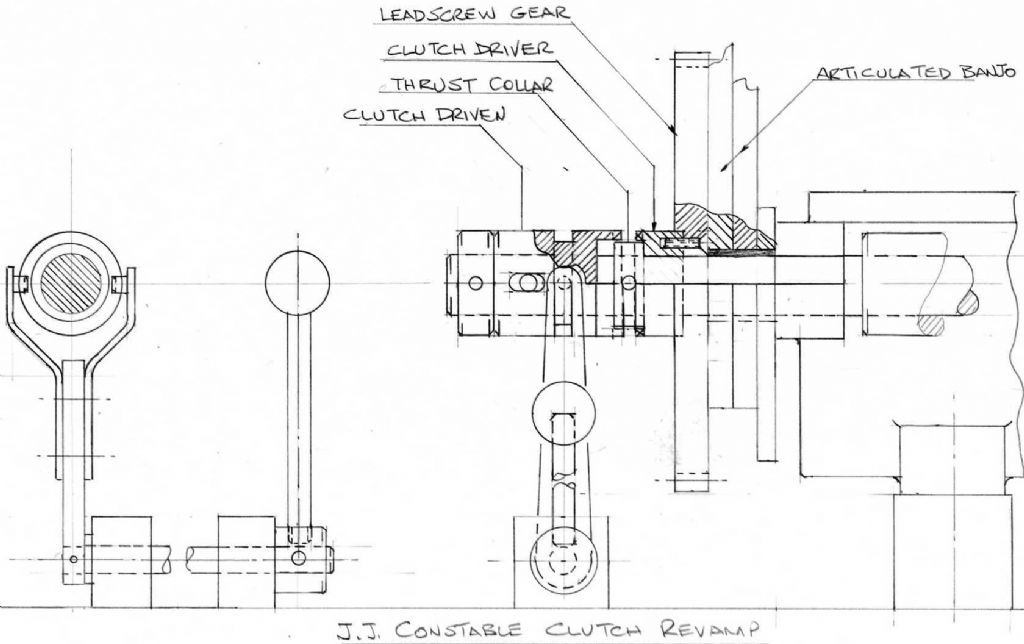

I then made the sketch that I include below, which is a small gearbox to enable the leadscrew handwheel to be positioned remotely from the leadscrew itself.

What has happened that the leadscrew has an extension which lengthens the leadscrew by 7/8", the downside is that the leadscrew handwheel shaft has to be shortened to 5/8".

By doing this, the length of leadscrew that protudes from the back of the lathe is now enough to enable the fitting of the "comfortable" variation of the JJ Constable clutch as shown in my last post.

I had to make a hard decision in that I will have to drill two 2BA tapped holes in the back of the lathe. There is also a clamp that is positioned on the forward face of the gearbox and clamps onto the forward face of the rear leadscrew trunnion.

I won`t make a complete description of the gearbox but will add some dimensions to the sketch should the gearbox be successful.

The next sketch that I will be creating is the clutch operating details and the automatic feed stop.

Please remember that this is an idea only!

Alan

Nigel Graham 2.