Hi EW Grafters,

I`ve been looking at the photos of EW lathes posted and would ask all EW owners that have not posted to add photos of their lathe so that we can see any variations that exist.

I have been looking into the slow feed design and have made preliminary sketches, overcoming the design challenges, but the sketches are not in a state to publish yet.

I remember the frustrations of owning the EW lathe back in 1953. my main gripes were that the lathe is too small to do any really useful work. I have to say here that I`m not a modeller and prefer to work on full size projects such as vintage cars. so here are my other criticisms:

1/ There is no slow feed for the saddle.

2/ There is no calibrated collar at the leadscrew handle.

3/ The calibrated collars on the cross and top slide are not adjustable.

I did modify the cross and top slide calibrated collars so that they could be easily rotated and am designing a calibrated collar for the leadscrew that will not impede the removal of the tailstock and as you know the design for the slow feed is in the pipeline.

My philosophy in the modification of historic items is that any modification made should be reversible which rules out any extra holes or modifications to original castings.

I`ve been looking into Martin`s designs and am amazed how prolific he was, basically he just scaled down the designs that he made for his Myford and added them to the EW.

I`m not knocking Martin, he was a clever engineer and a leading light of his time, I think that we should look into the social climate of the fifties and sixties to get an insight into the mind set of the male population, I know, I was there.

Generally in the fifties people did not benefit from the huge range of activities that exist nowadays the range of activities was limited for example to watching football on Saturdays at the ground not on TV where the programmes were very unsophisticated ranging from "Muffin the mule" to "Henry Halls Guest Night". There was the Pub of course where one could drink lashings of watery beer and stagger home. The other way to spend the excess time on their hands and keep clear of "her indoors" was to beaver away in little sheds producing all sorts of things that modellers do.

Nowadays our male population spend most of their spare time watching TV football and have no time to spend on modelling projects. If they need a piece of machinery they just go out and buy it and probably have more than one machine, it`s not a big deal as it was then, where small cheap machines were upgraded to be all dancing and singing such as the EW, which apart from a drilling machine, would probably be the only piece of machinery in the workshop and so had to do everything.

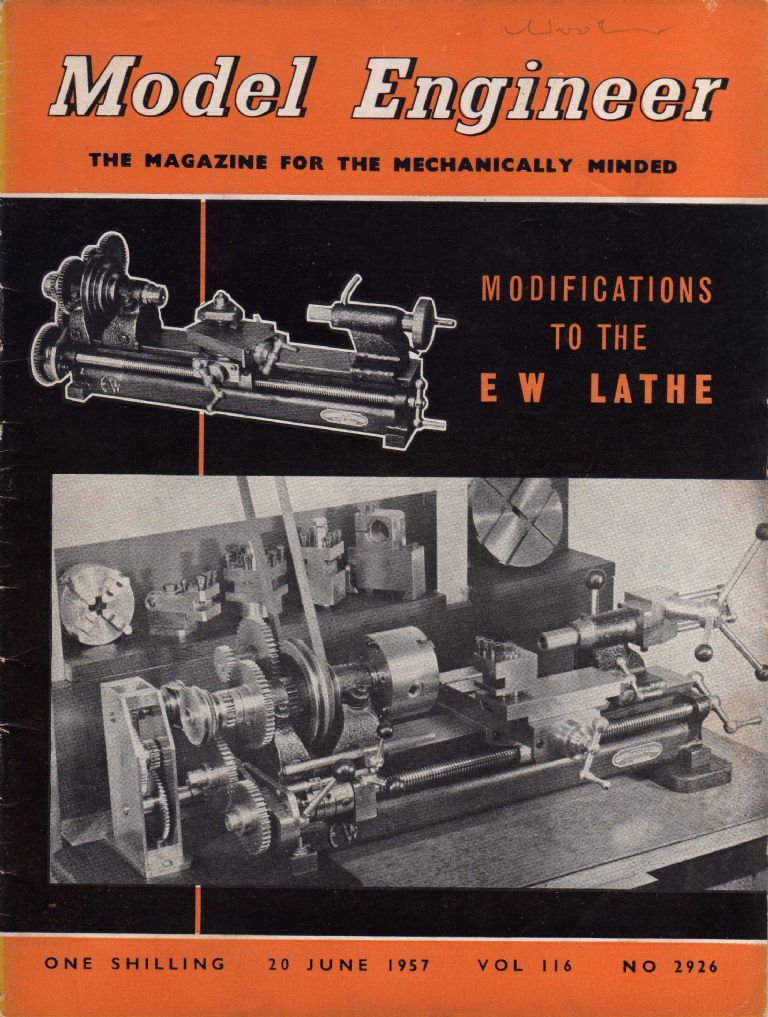

When I looked at the front cover of ME 2926 which depicts the modified EW lathe my impression was that it looked like an overdressed Christmas Tree. I will continue on this theme shortly and review Martins modifications to the EW in the light of the needs of the 21st Century modeller.

More anon,

Alan

Edited By alan smith 6 on 19/08/2012 16:23:32

Nigel Graham 2.

,

,