Hello All EW owners

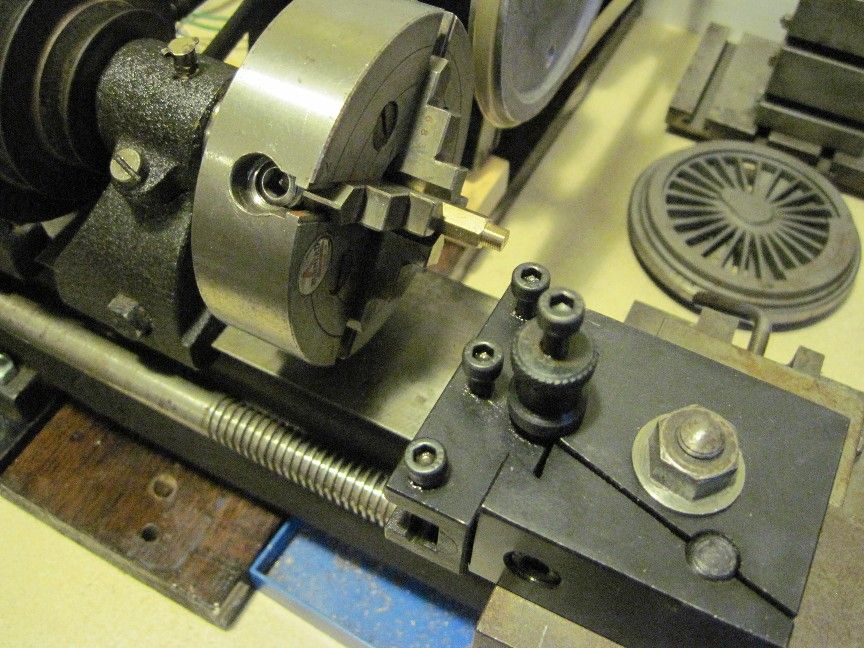

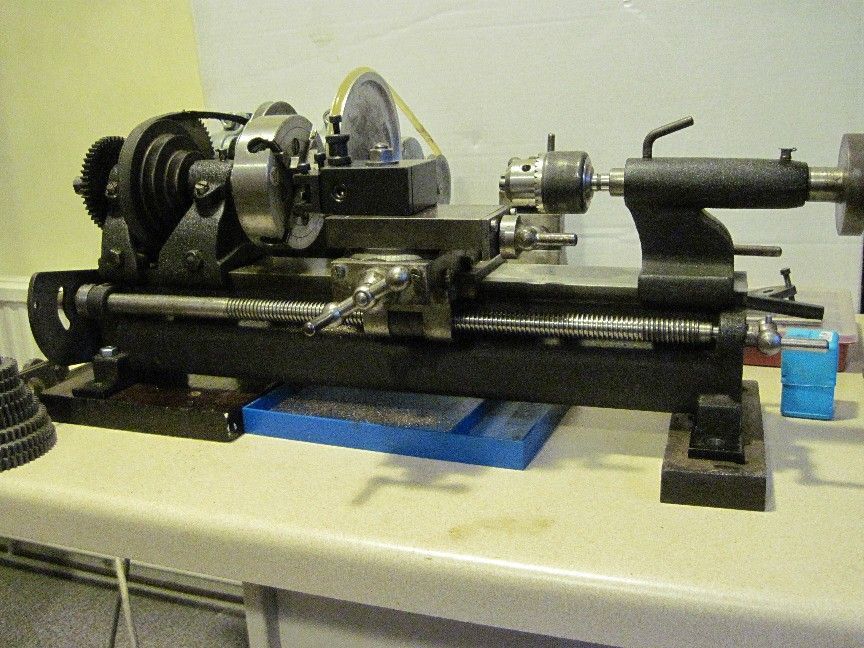

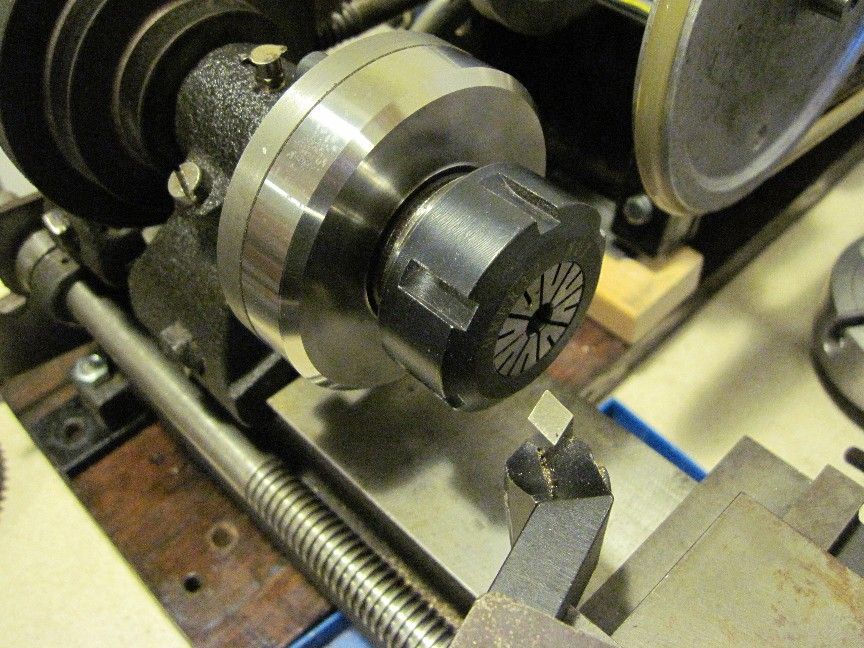

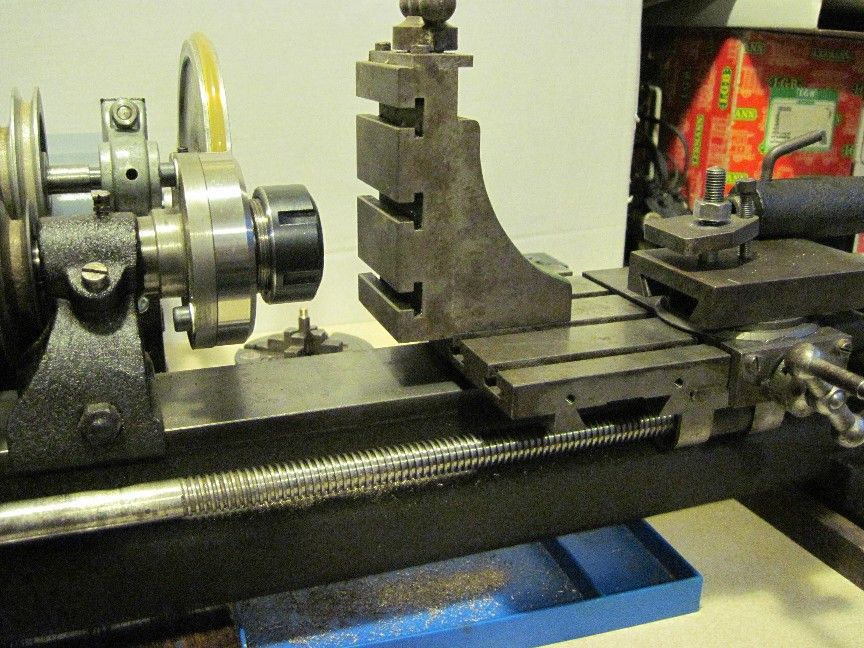

I’ve recently acquired an EW lathe – or at least part of one – bed, cross and top slides, headstock, spindle and lead screw, and subsequently manged to source a tail-stock of the correct pattern for the age of the bed. My original reason for getting the lathe bed, was to incorporate it into a tool grinder, but when I collected it and saw the tail-stock on offer separately, it became a restoration project! It even looks as though an old chuck and backplate picked up on the off chance about 12 months ago will fit as well!

The bed on my lathe is the pattern with the extension to the tail-stock end and it has a gap, so from lathes.co.uk it looks like a fairly late version.

However I could do with a bit of information about these lathes however before I go much further.

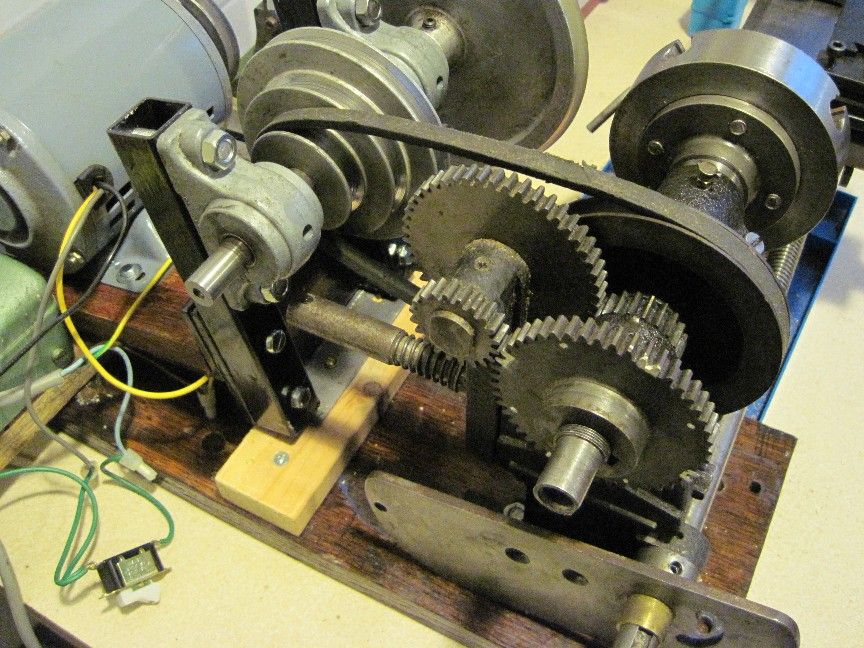

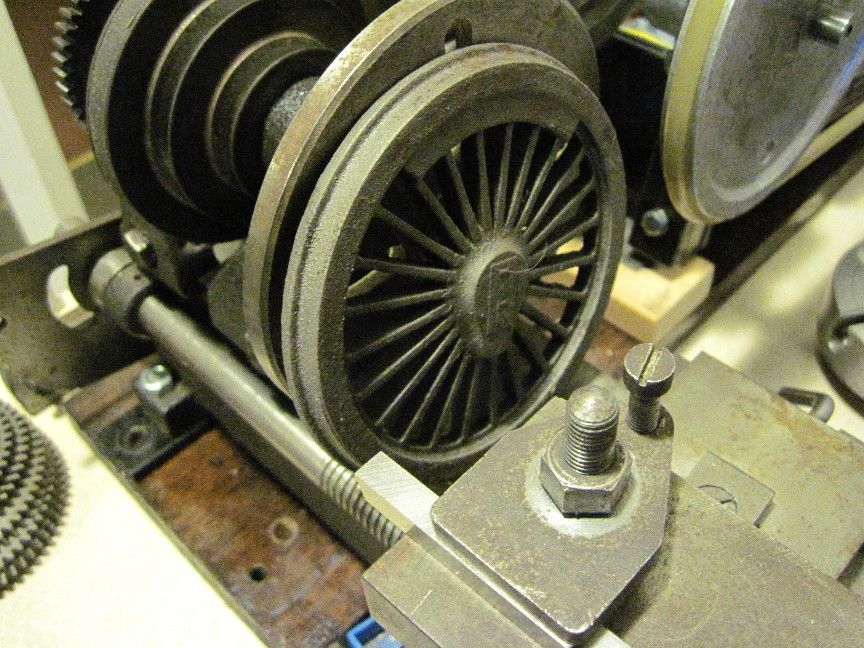

I’m missing the back gear bracket, shaft and gears, although I’ve got the necessary gears on the main spindle, so that looks like a manufacturing job. But looking at the pictures that you’ve posted and those on the lathes.co.uk website I can’t see any signs of a clutch any where in the lead-screw so it looks as though thread cutting under power could be “interesting” especially up to a shoulder. Do your machines have such a clutch and I’ve just not spotted, it or will this be an “owners modification” that I wish to carry out. At the moment I don’t have any change wheels for the EW but I do have loads for my Drummonds which at 14 dp rather than 16 dp are too big on the face of it but if I incorporate a clutch, then that has to go somewhere, and I think the easiest would be to move the change wheels further to the left of the headstock and make up a suitable banjo and mounting to suit with the clutch between the change wheel array and the end of the lead-screw. – I don’t want to modify any original parts if can avoid it.

Any advice or comments will be most welcome. This machine is too good to mess about, it deserves to be restored and set up as a lathe!

Keith

Nigel Graham 2.