Hallo Isaac,

No one seems to have ventured to give you an answer, so I thought I would try to help a little (although this is a very subjective area in my view).

First, I think you should differentiate between what we might call the "precision" surfaces (e.g. the lathe bed) and other (less) "precise" surfaces – such as handles and chuck bodies. Let's deal with the latter first.

Old machinery that has 'bare' surfaces often suffers to a greater or lesser extent to rusting if neglected (and sometimes even when cared for). This can range from severe rust & pitting to light surface rust. There are two approaches to removal – either chemical or mechanical – and I guess there are combinations of the two where some abrasives are involved. For light 'tarnishing' careful rubbing with fine wire wool (not the kitchen type) or other fine abrading materials will often bring up the surfaces very well. Remember to lightly oil the cleaned surface immediately afterwards.

For heavily rusted areas, then some form of chemical (or possibly electro-chemical) process can be used – my favourite is immersion in citric acid (eBay Indian cooking suppliers) – however although this will remove the rust – it cannot repair any underlying damage or pitting. There is not too much that you can do about bad pitting without re-machining the surface or perhaps just filling and panting over it. On some surfaces (handles for instance) you might be able to 'buff' up the surface (with a suitable buffing set-up) and simply accept that you are buffing up a pitted surface. I've done this in the past on some small handles that I didn't want to paint and although the surface was still badly marked – it was at least now a 'shiny' handle and looked better and nicer to use (in my view) than just leaving the way it was. (Purists will probably be having fits by now).

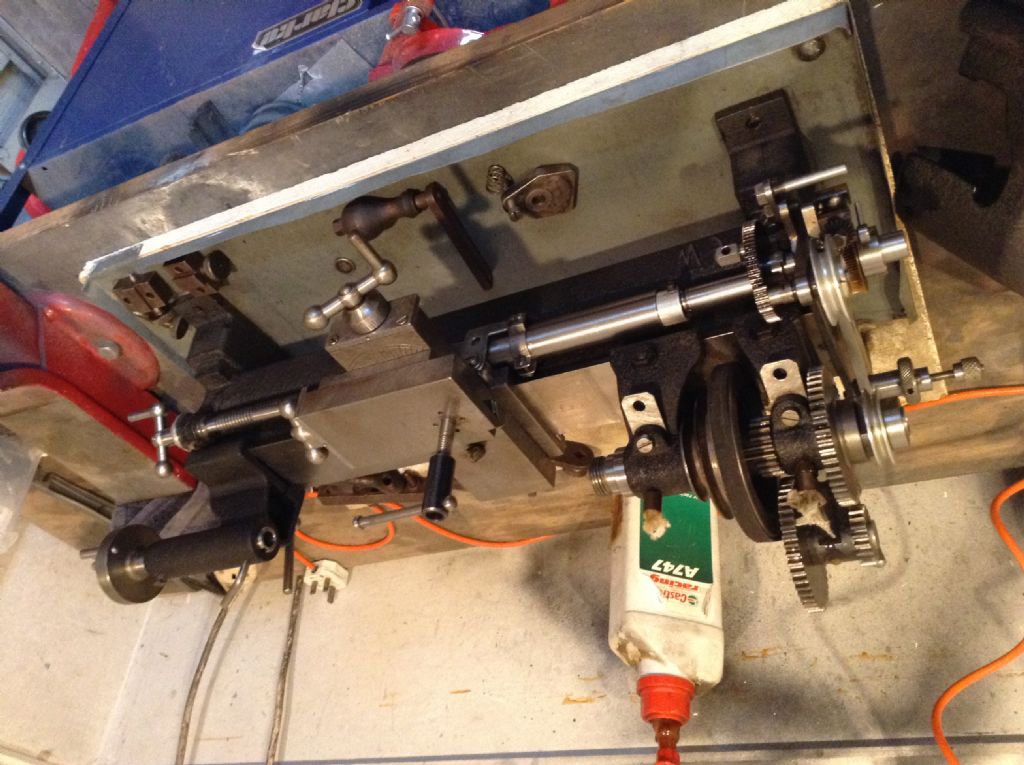

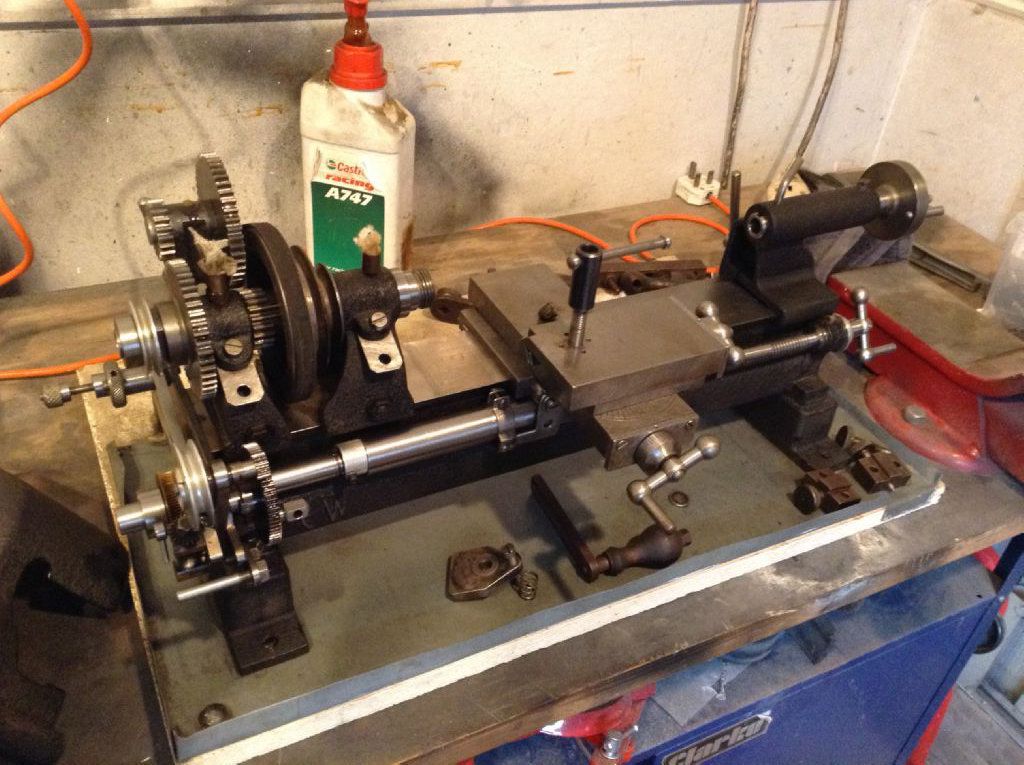

The best advice I think is to be patient and not rush into anything by being too aggressive (or using too aggressive or coarse polishing agents). I'm also assuming that you have also had the patience to carefully dis-assemble and clean everything before deciding the best 'restoring' approach for each individual item. So (for instance) take that chuck completely apart before you try to improve/restore the finish of the body – and after you've worked on the body – wash it again in white spirits to get any cleaning agent/debris off before you re-oil and assemble it.

As with many things on the forum – it would be much easier to demonstrate these methods to you than describe them but that (very quickly) is how I personally approach "non-precise" surfaces…

As for "precise" surfaces – my advice is to clean and lubricate them and then carefully re-assemble and adjust them – BUT (other than that) leave them well alone.

If they are so badly damaged that this is not sufficient – then the machine probably wasn't the right one for you to start with. It may well be possible to restore these surfaces but it's generally not a job for a beginner. I might add that the top surface of my EW lathe bed is badly 'stained' (something has been spilt on it) but that as far as I can tell – this has not effected the lathes accuracy in any way. It's annoying but seemingly just cosmetic, so I've left it well alone.

Machine restoration is a large subject (books have been written about it) but take your time and perhaps work on (and test) a small area before getting really stuck in and I'm sure you will be pleasantly surprised at how nicely old machinery surfaces can come up. Perhaps not as new (unless you really spend a lot of time on them) but more than good enough to look workman-like.

Hope this helps you get started – even if just a little.

Enjoy your EW Isaac, they are good little machines and well worth caring for.

Regards,

IanT

Nigel Graham 2.