EWers and Bookmarkers,

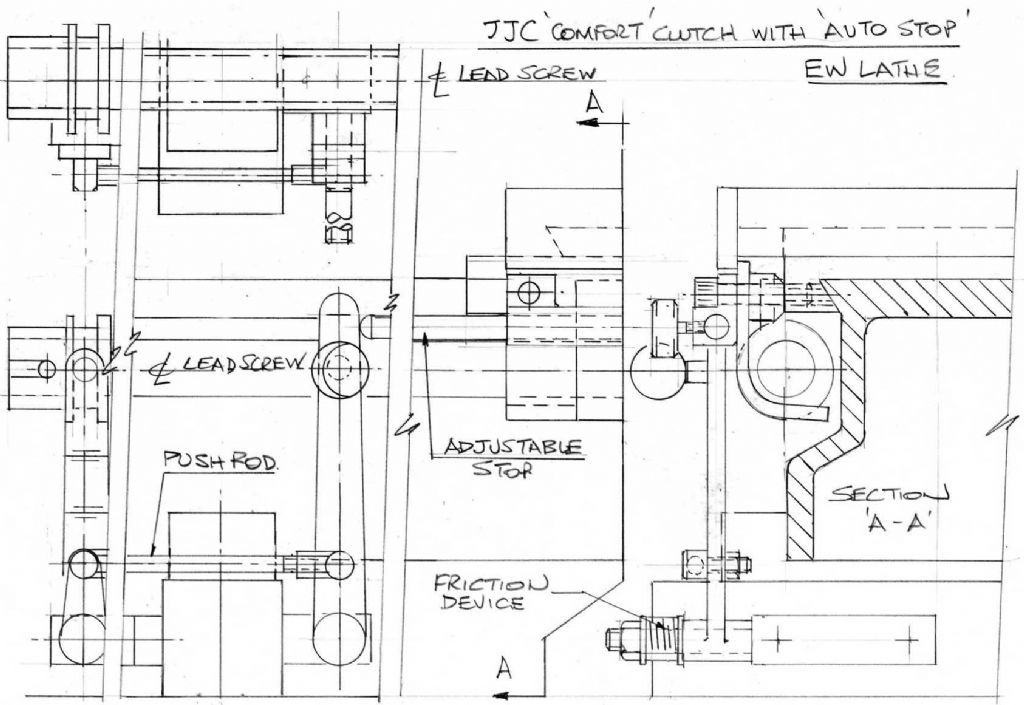

I enclose a scan of my latest idea for a dog clutch incorporating an adjustable stop for the slow feed.

I make no claims as to originality, what I have done is to throw all the ideas put forward, into the cerebral mixer and churn this out. Of course this idea can be adapted or improved by the reader as required.

What I have done is to leave the clutch lever in the original position as for the Martin Cleeve split leadscrew as shown in the first sketch. Extended the leadscrew at the headstock end by adding the extension piece as proposed in the leadscrew gearbox sketch and added the JJ constable "comfortable" clutch as in the JJC variations sketch.

So now we have a dog clutch that works without having to split the leadscrew, therefore eschewing a possible intermediate support for the split leadscrew.

The pushrod to actuate the clutch has to be placed low down in order to miss the slow feed gears. I recommend that the adjustable pushrod have ball joints at each end.

As for the adjustable stop, this is operated by a 1/4" dia rod adjustable axially, which pushes against the clutch operating lever therefore pushing the clutch out of engagement. This is mounted in a bracket that is fixed to the saddle by elongated leadscrew nut bracket screws. Remember to cut away the bracket so that there is access to the leadscrew nut adjusting screw.

The clutch operating lever requires a good base dia length to avoid deflection by the force of the clutch stop pushrod.

I should have done the sketch on two sheets and hope that those unused to engineering drawings will understand it. On the right hand side of the sketch is section AA, looking towards the headstock and to the left is a front view of the lathe in the area of the clutch lever. This view is shortened by splitting the view with the two vertical break lines. There is a small plan view in the top LHS of the sketch

The friction device is just a strong compression spring which will prevent the clutch lever from wandering out of the desired position.

This idea can be used either for the Martin cleeve variation or the JJC variation.

I will be investigating both situations by making prototypes when I have time.

Alan

Nigel Graham 2.