Hi folks,

I am looking for informed opinion on the strength of cast iron when subjected to an extracting force of about 16kg via either a M6 or a M8 bolt.

In MEW 251, Phil Dawes describes how he modified his SX2P milling machine by replacing the spring loaded side lifting arm by a counterweight system. As I have a Warco MiniMill (X2 clone) using the same system, I thought that it should be possible for me to do the same.

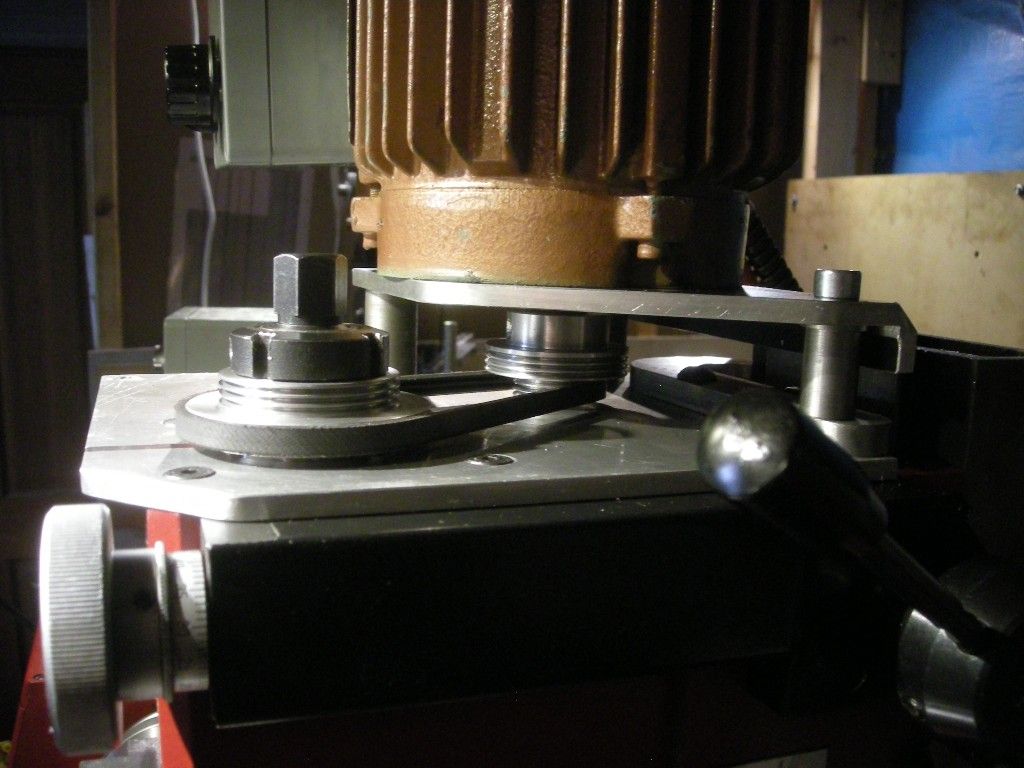

Phil says that he was able to attach the lifting chain to the milling head by means of the two rear bolts holding the motor to the head. As the photo below shows, I do not have those screws, and the two nearest screws do not have sufficient room to have a suitable bracket attached.

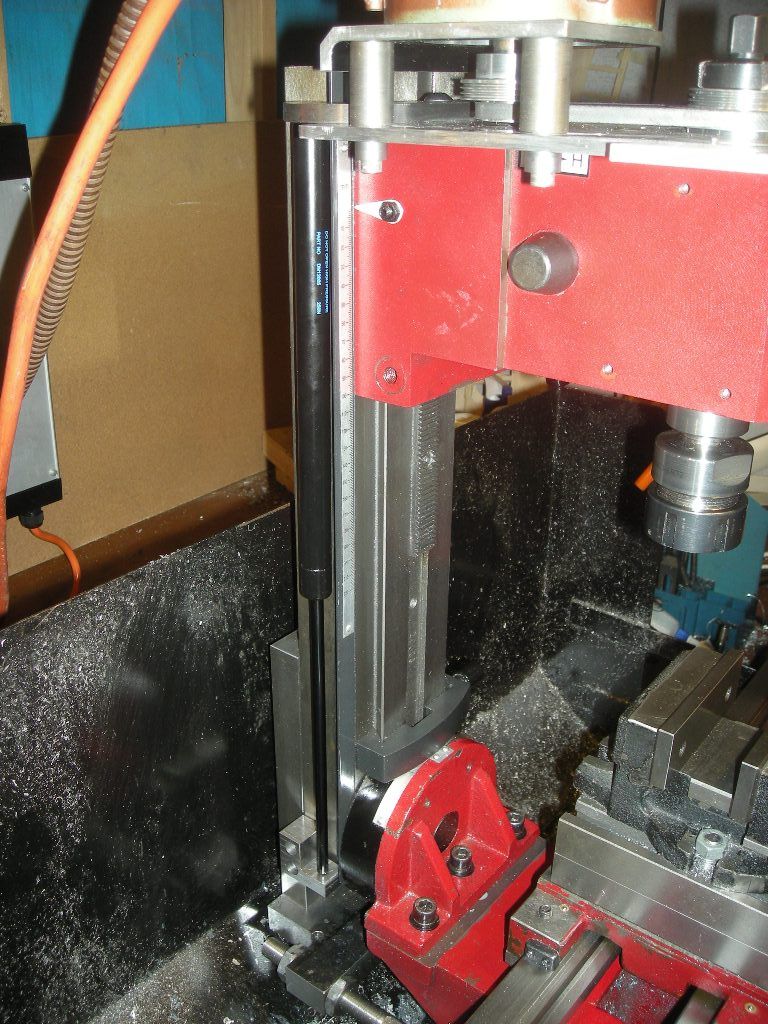

It seems to me that my alternatives are to either replace the cast aluminium spacer between the motor and the actual milling head with a longer spacer but this then poses problems with creating the spacer on the lathe, the lengthened spacer being 200mm long, or to fasten the lifting chain directly into the dovetail section of the milling head.

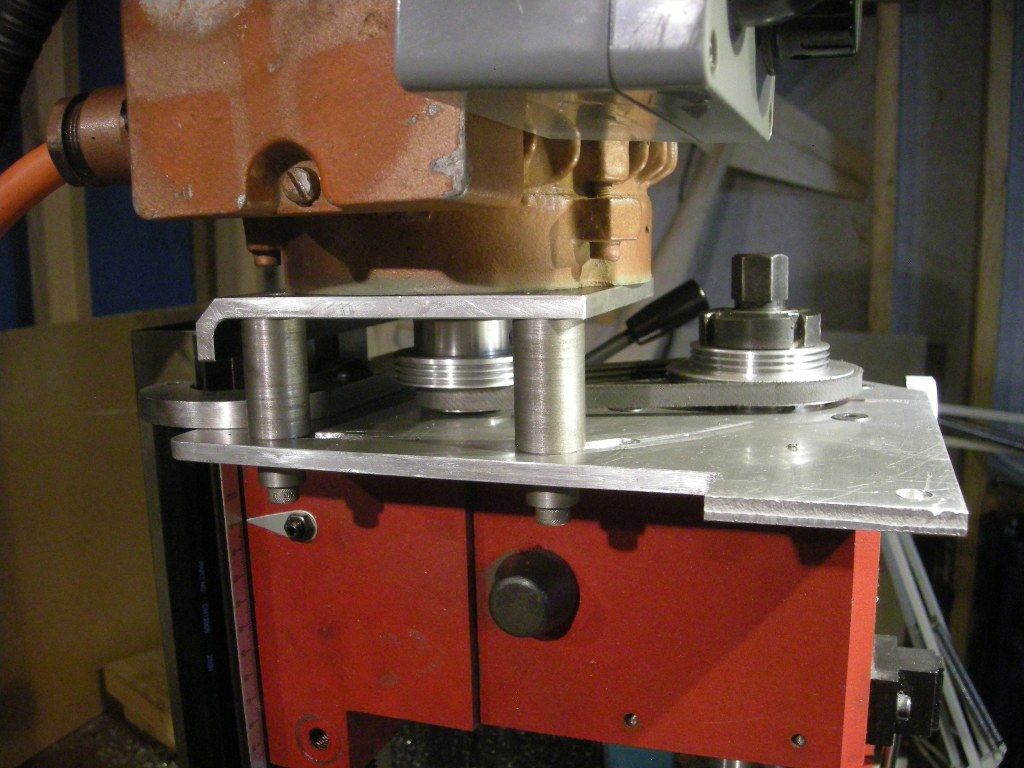

The flat surface of the dovetail is about 23mm wide where the rectangular cutout is whilst the vertical thickness is 11mm.

The second photo shows a close-up of the rear of the dovetail.

You will be able to see that there are caphead screws down the two holes, whilst in the middle of the cutout section can be seen a dowel which serves to ensure that the two halves of the head are correctly located.

As I see it, I can either use a single M6 thread or a single M8 thread into the top of the dovetail, hence the thread would be 11mm long. I suspect that M8 would be better as then the individual threads would be thicker, and therefore stronger. Alternatively, I could shape a piece of 6 to 8mm thick steel to fit inside the curved section with a clear hole through the cast iron. This would have the effect of compressing the cast iron and at the same time spreading the lifting load over a larger area.

Ideas & thoughts please. Incidently, I am proposing only using one screw through the cast iron. I feel that providing two screws, even if only M6 might weaken it too much.

MTIA

Peter G. Shaw

Ian P.

Ian P.