I moved the on off switches to the front of the bench the mill sits on, rather than reaching up the right side of the mill to the rotary switch there, I keep(occasionally) thinking it would be an idea to put a long flap along the bench so the off switch can be activated with a bump of the hip, or knee.

For the last hour or so I'v been looking for the correct grade of carbon for making pistons. The web site for a supplier in Australia that I had seems to have disappeared. The place to find it (used lumps) is a foundry, or some where that does spark erosion/ die sinker. Or a place that supplies goods to those sort of places.

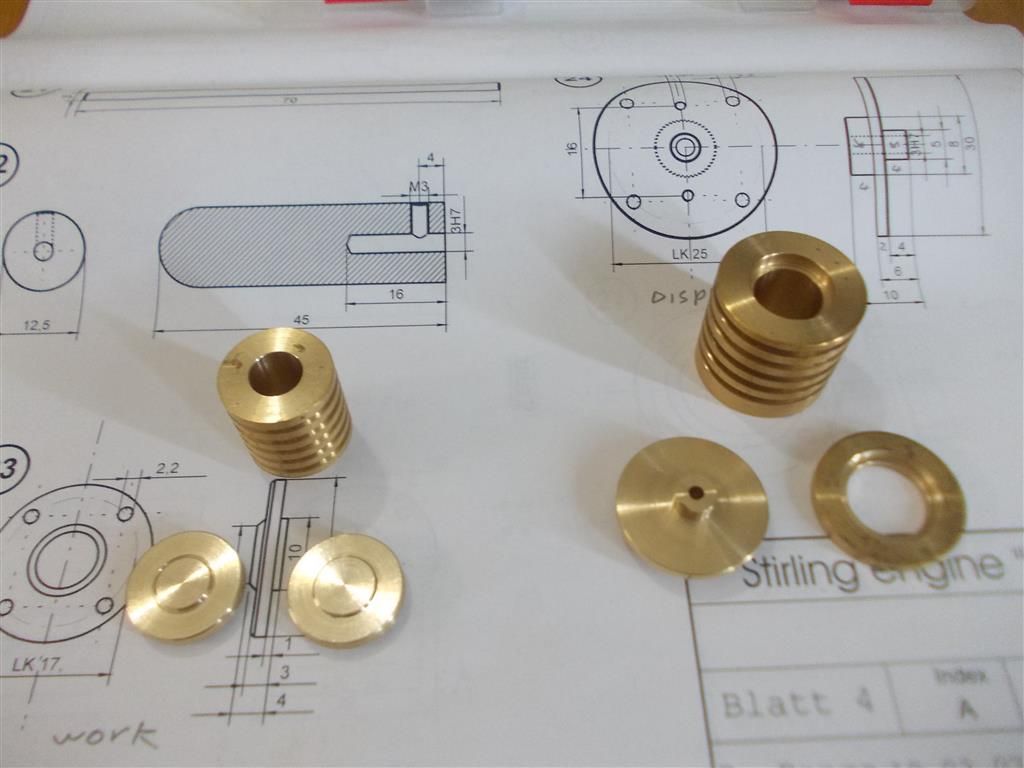

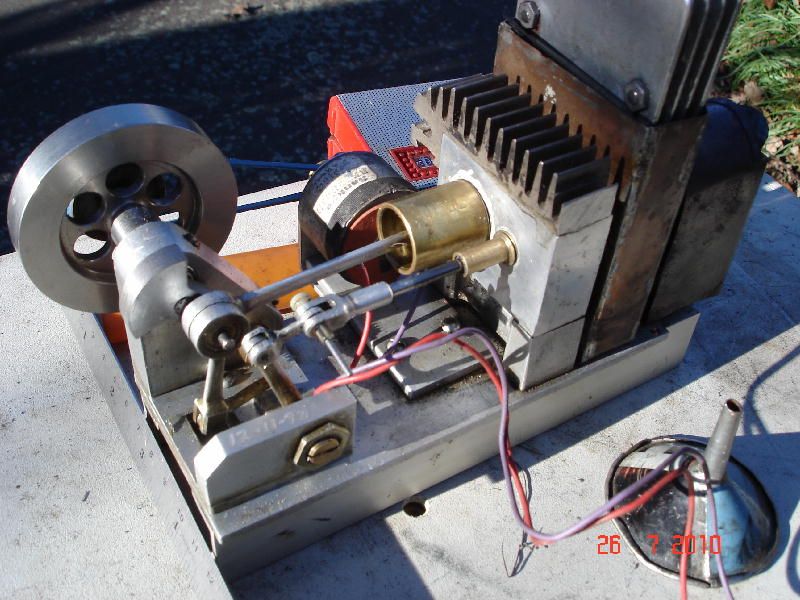

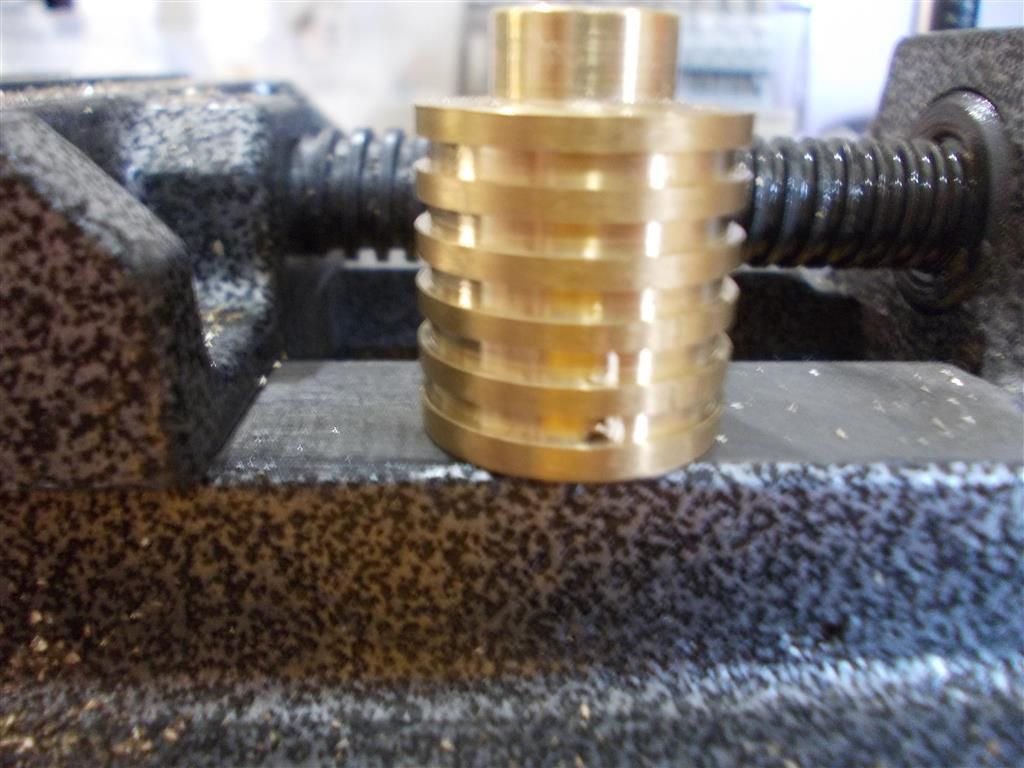

Gordon, The piston in that motor is 5/8" diameter, and the sleeve was made by boring out a bit of carbon impregnated Teflon bar. To make your piston, I'd make it with good amount of clearance, and use two,(one at each end)Teflon rings, these being made by getting a bit of Teflon sheet, 1 mm – 1.5 mm, or what you can get, and cut it to about 1/4" wide x the circumference, the joint is best formed as a step on each end, or it can be a diagonal cut. With the two rings the aluminium wil be clear of the bore. Make the piston hollow. In the photo you can see one of my cast iron pistons, this one is 30 mm dia, the engine is a stove top fan.

Ian S C

Gordon Tarling.