I have been working at night and sleeping all day so my apologies for the delay in replying.

I did successfully cut this thread using the lathe : the tailstock was used to keep it straight. This is my preferred method of cutting threads. But I was not happy with the shoulder so I attempted to clean it up a bit by putting the work piece in the vice and recuttting it ; this is when it broke. I should have left it alone. I did try to cut the thread in the vice from the start but I could not get it to start.

I have removed the broken piece using a hacksaw blade. Unfortunately the die has been damaged. You can see that two of the thread cutting pieces are broken off so I will have to buy another one. I think the damage occurred when I tried to drill it out. My drill press is rubbish ; I should not have even tried to use it for this.

NOTE : the die could not be opened up enough using the centre screw…not even close.

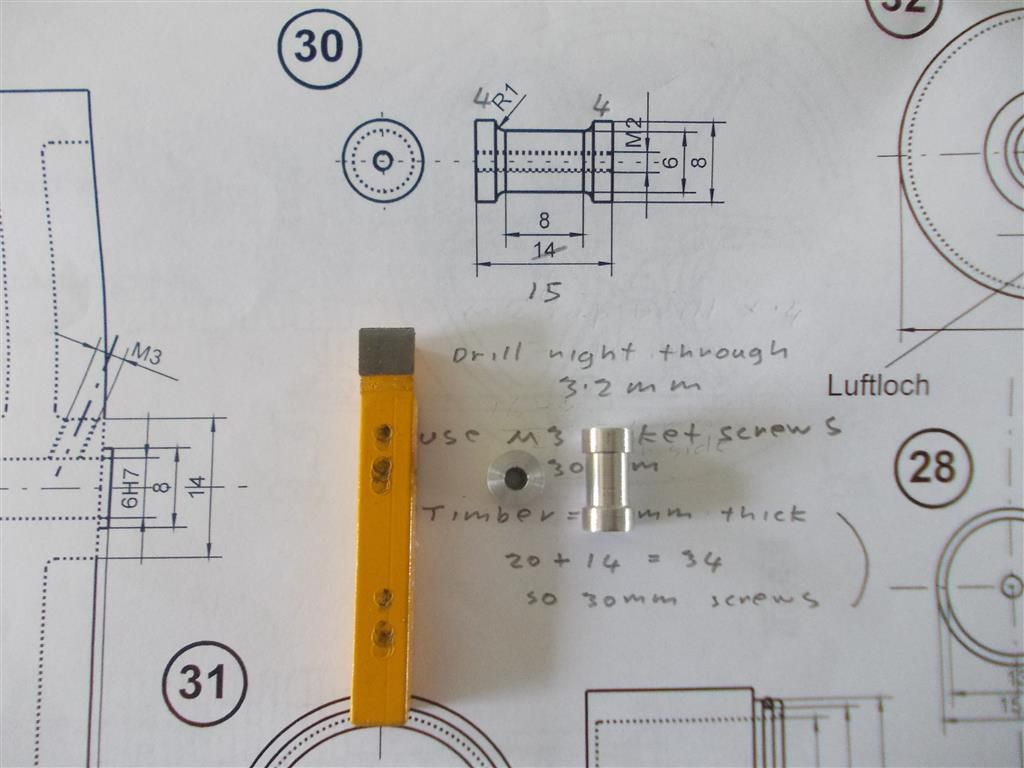

I did reduce the piece down to 1.9mm before cutting. I did put it in the lathe to keep it square. I initially had the dremel tool set too high and as you can see it burned the metal a bit ; I have now lowered the speed. Today I cut another three of each of parts 10 and 11 ready for the 2mm dies when it arrives from the UK. I also cut some pieces in stainless steel rather than silver steel. I will see how that goes when the die gets here.

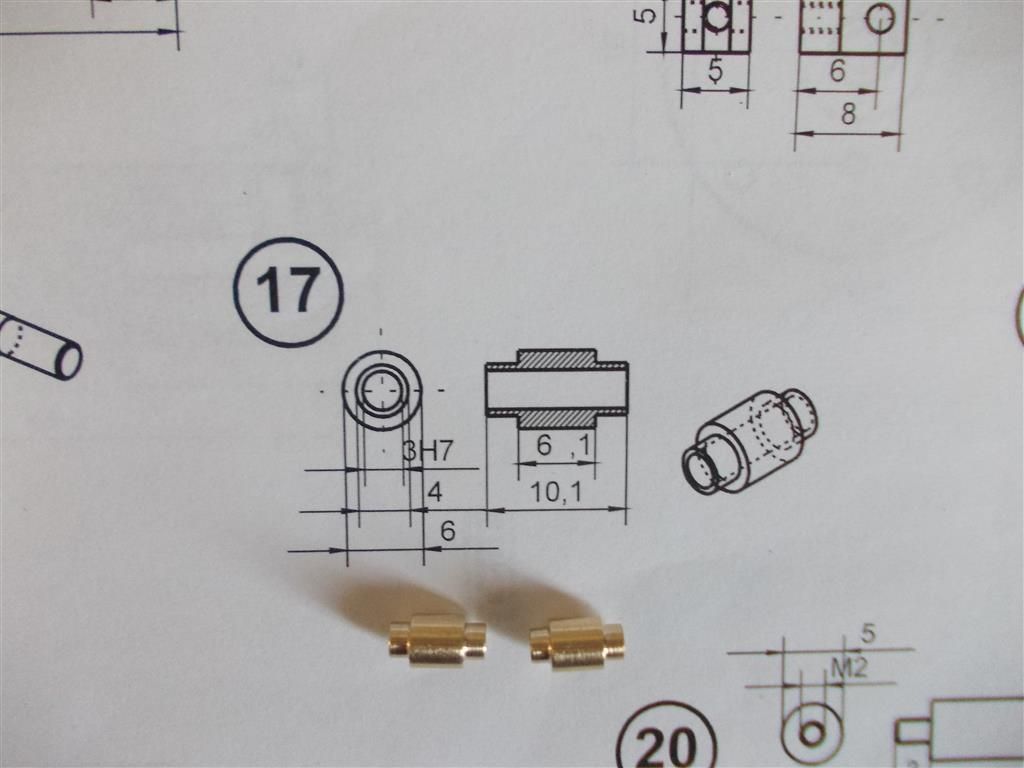

Making these smaller pieces is turning out to be more difficult than the larger pieces. My camera is terrible at close ups.

Edited By Brian John on 27/11/2015 06:13:56

Edited By Brian John on 27/11/2015 06:15:26

Edited By Brian John on 27/11/2015 06:18:58

Gordon Tarling.

Must admit 1D gives me the wobbles so always go for a bit more and also often can't be bothered to shorten screws and bolts. On the other hand 10BA only needs fully tapping to a depth of an 1/8" tops really and that is very likely to save breaking taps.

Must admit 1D gives me the wobbles so always go for a bit more and also often can't be bothered to shorten screws and bolts. On the other hand 10BA only needs fully tapping to a depth of an 1/8" tops really and that is very likely to save breaking taps.