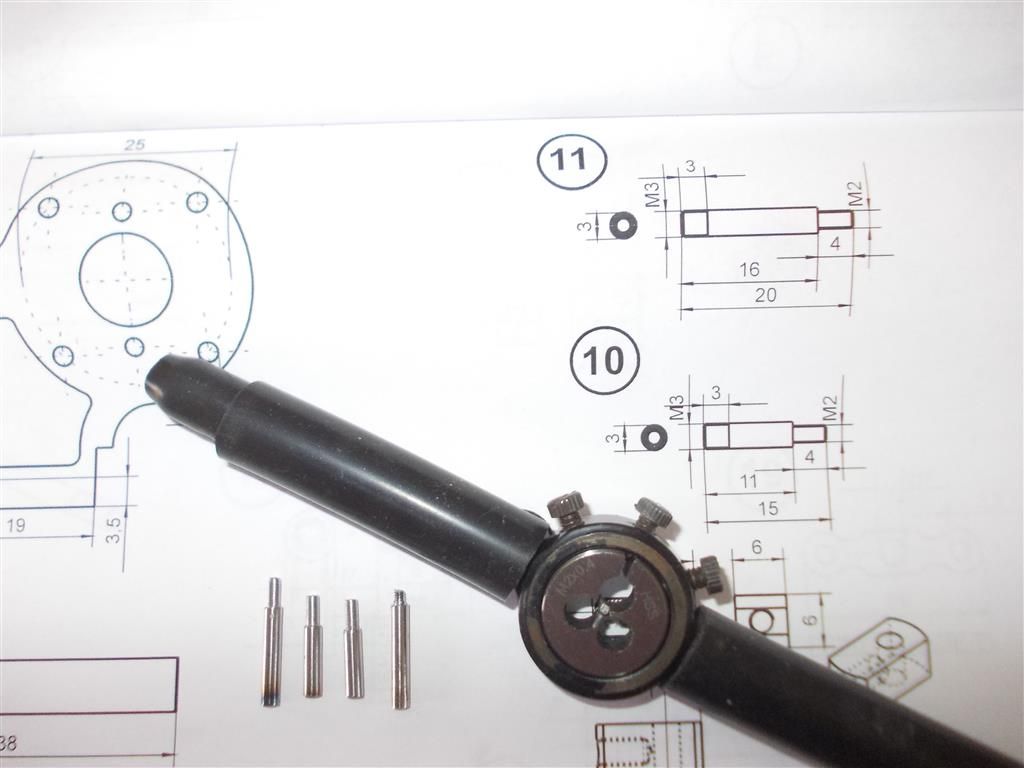

A couple of things to make using a die easier:

Turn the diameter of the bar down to 3 or 5 hundredths of a mm smaller than the nominal 2mm.

Turn a good chamfer on the end of the bar to help the die get centred and get started.

Make sure you use the end of the die that has the gently tapered teeth as the leading end so the first teeth cut only a shallow thread, the next teeth a bit more, and so on.

Turn the die about half a turn forward then about quarter of a turn backwards. You will feel the chips break off and the die move more freely. This helps break up the swarf and lets it drop out instead of jamming up the die.

Use some kind of lube, tapping fluid, oil, WD40 etc.

Keep checking the side view to make sure you keep the die and die stock level in all directions as you progress. Or hold the job in the lathe and use the tailstock to hold the diestock square. But still use the half a turn forward, quarter of a turn back routine.

Gordon Tarling.

I've resisted building any sort of engine for a long time but of late am weakening.

I've resisted building any sort of engine for a long time but of late am weakening.