Hopper : yes, they all look to be the same. I guess I will have to live with it and work around it ie. stick to working at the top of the throw.

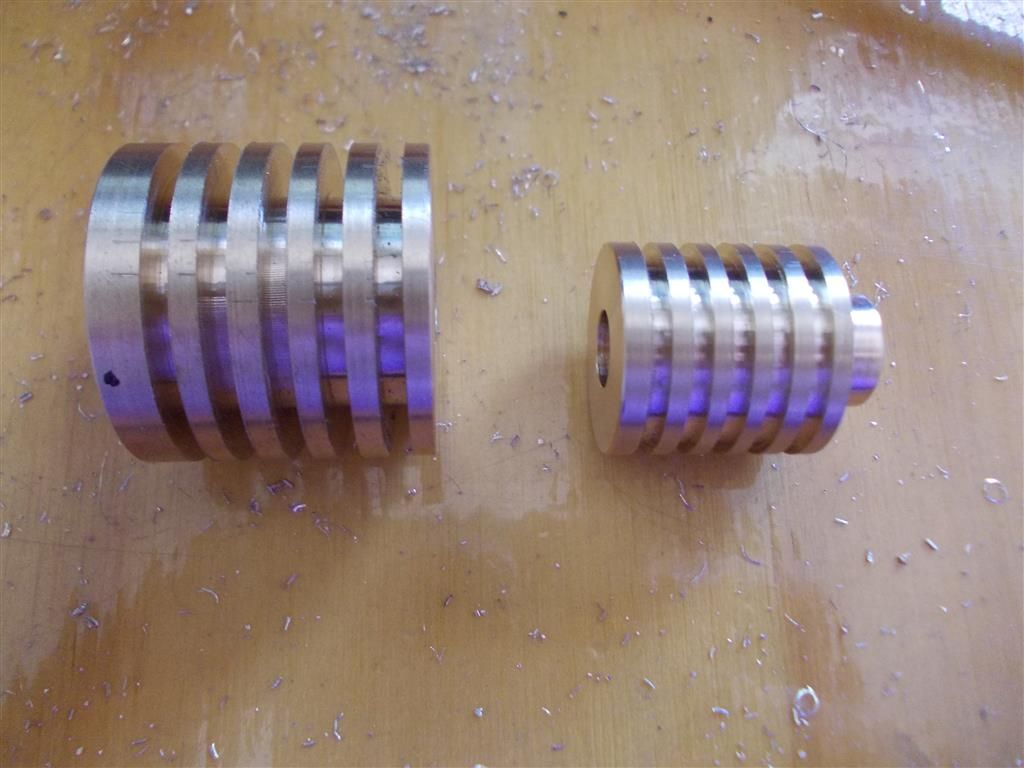

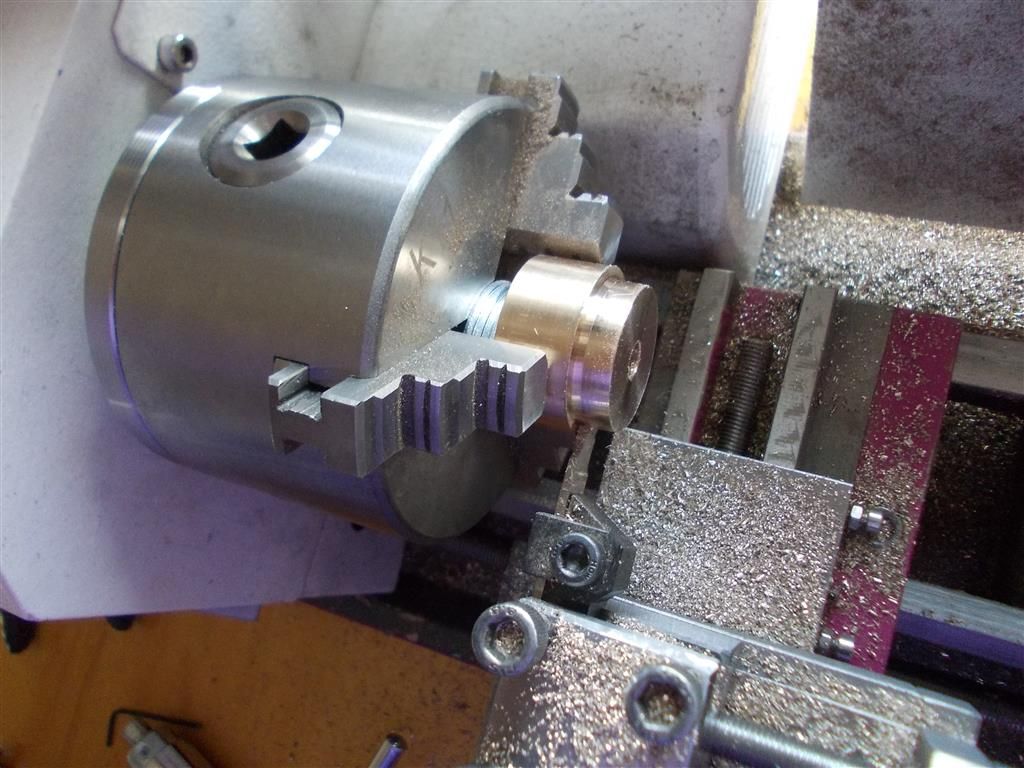

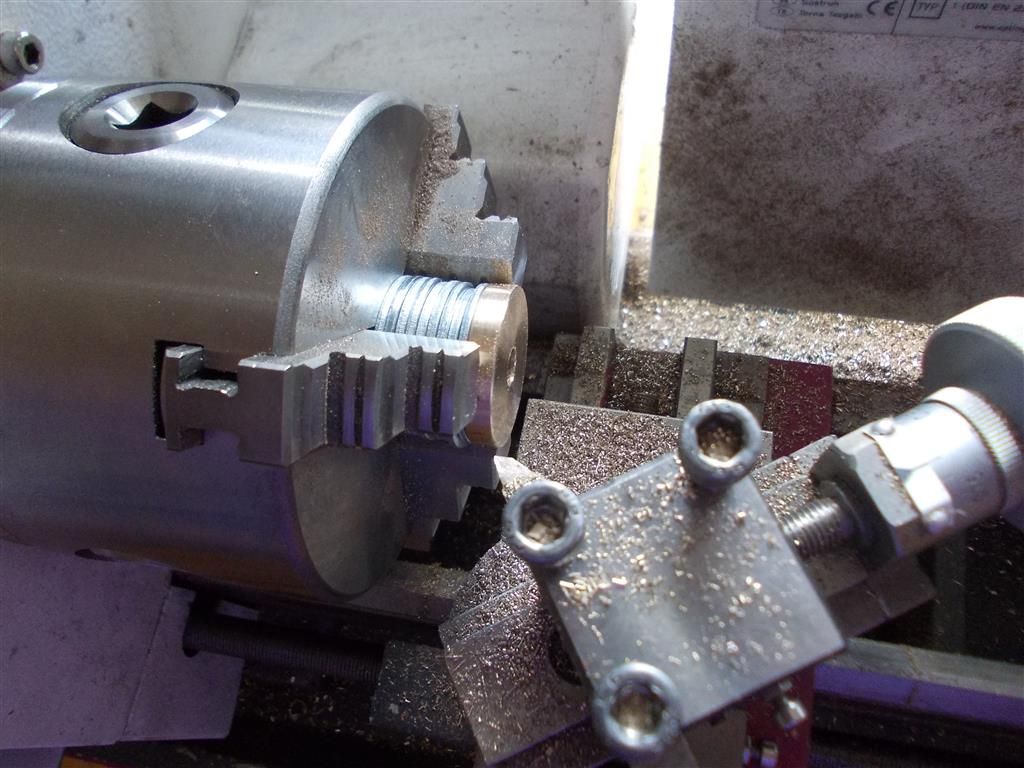

Parting off problem solved : when I was getting a dome shape on the 19mm discs somebody asked if there was an angle on the parting off tool. There was an angle so I had filed it off flat. But it would appear that an edge is needed so I used the bench grinder (first use of this tool ! ) to restore an angle. The original angle had the leading edge on the left but I put the leading edge on the right to eliminate the dome effect on the disc. This seemed to work well and the brass peeled off nicely. I managed to successfully part off three 25mm discs today. I put the discs in the chuck supported by washers to take a facing cut and clean it up, taking it back to the required 4mm thickness…well close to it !

I will make a few more 19mm and 25mm discs tomorrow. I am not confident of cutting out the cranks and I think I will be going through a few before I get it right. I need to plan this operation better as I cannot do it by eye.

I was not initially parting off with the work piece supported at the back by washers as per the photo but after cutting two discs there was not enough brass left so I decided to see if I could cut a third by using the washers…getting a bit cocky now !

I did not have any luck supporting with the tailstock as it left a chamfer on the inside of the hole even though I had only screwed it in lightly (or thought I did). Once I put an edge on the parting tool then there was no need for it anyway.

Edited By Brian John on 21/10/2015 08:35:44

Gordon Tarling.

It may be okay to do that now with a flat edge.

It may be okay to do that now with a flat edge.