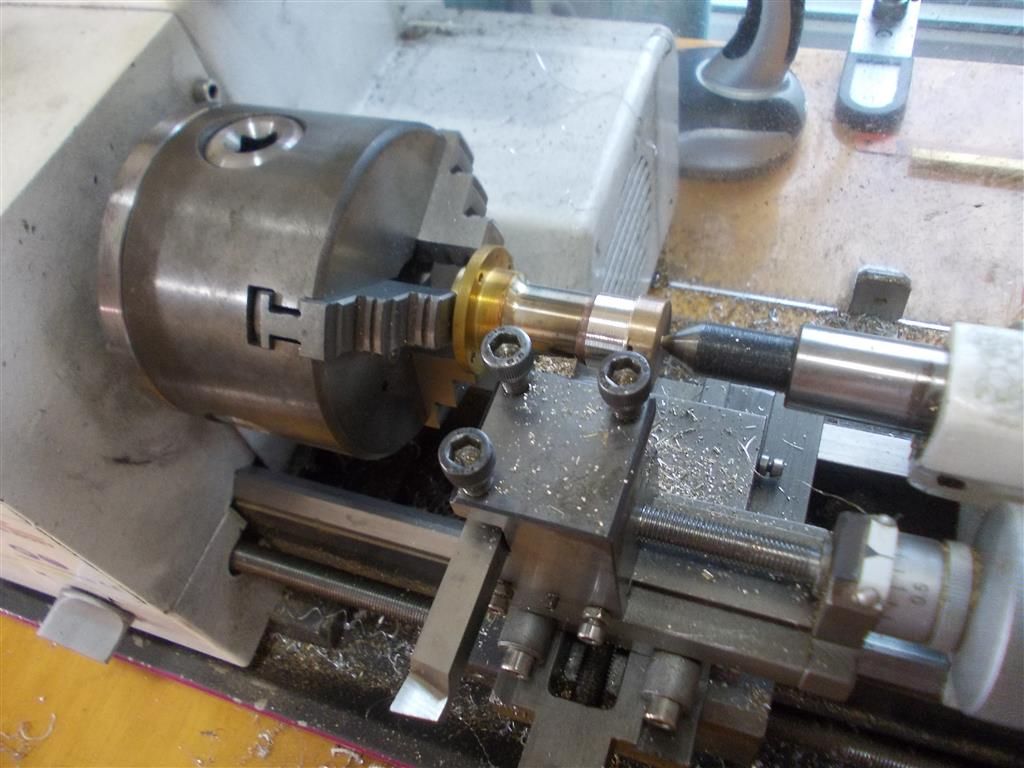

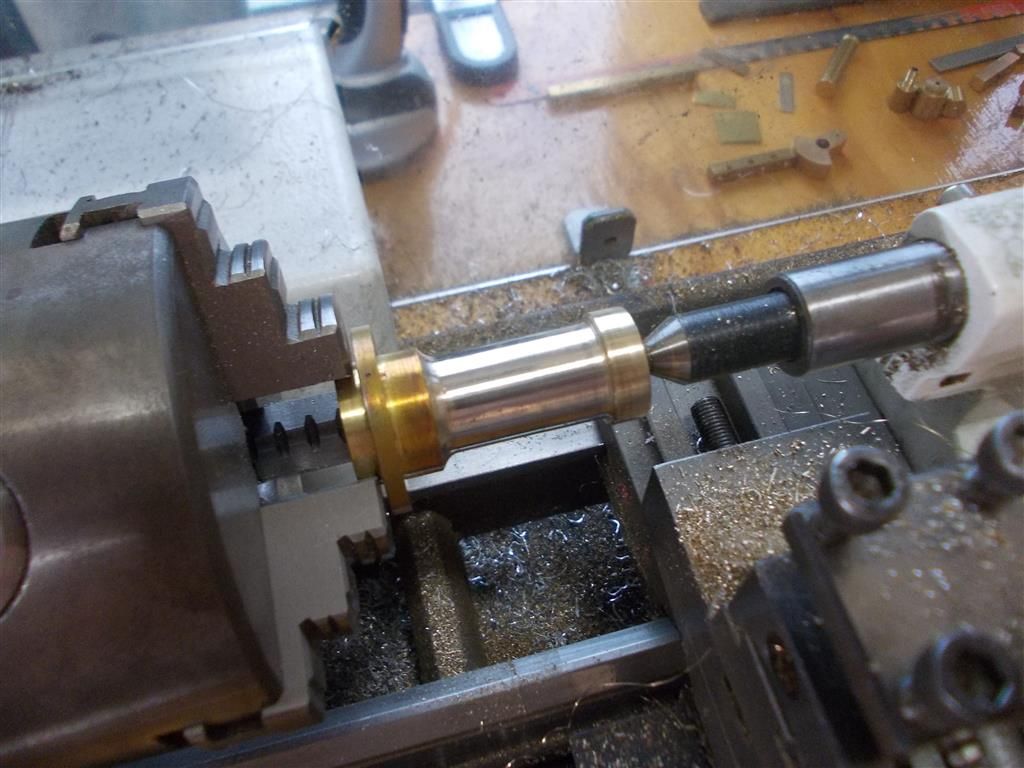

I bought some exhaust manifold gasket material today but that idea went nowhere. How do you cut this stuff ! I hammered away it it with hole punch for 10 minutes and got nowhere. Even a sharp scalpel blade is useless. Anyway I gave up that idea and moved on to making a stainless steel D piston from the 12.8mm OD stainless steel tube.

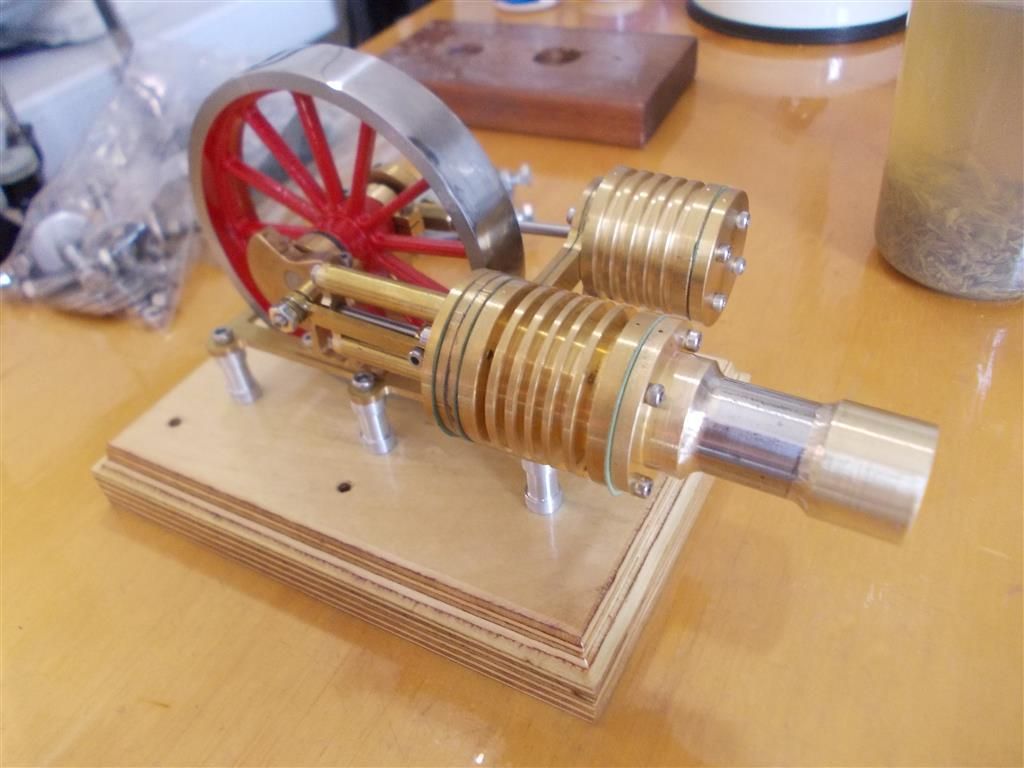

Initially I was going to make the two ends to the piston from brass and then silver solder them in place but then I had this idea (how many times do we hear that !). I have put an M3 thread in the'' hot'' end , the piston rod is threaded so that it screws into this after passing all the way through the brass fitting at the ''cold'' end. That brass bush is held in place with an M3 grub screw. Looks good but will it work…I will give it a go later tonight.

The stainless steel is tough stuff and I comepletely destroyed my M2 spotting drill. Ideally the tube would have a thinner wall : 1mm would be good but for now I have stuck with the original 2mm wall. I am not sure how this stuff would go with a boring bar. I might give that a go tomorrow if I make another piston. I was able to clean up the ends in the lathe with no problem so perhaps machining it is easier than drilling into it. Even tapping it was no problem with plenty of tap magic being used.

Edited By Brian John on 14/05/2016 08:22:39

Edited By Brian John on 14/05/2016 08:25:10

Gordon Tarling.