I have been without the internet all day until now so forgive the late reply (thank you Telstra!).

Much mucking about today with still no success. I have read all the above just now and there is a good chance that this engine will never work as it conducts too much heat from one side to the other too quickly. However, if the glass tube version will run for well over 20 minutes then this version should at least run for 5 minutes…would you agree ? Also, I have put gaskets between the hot cap and the D. cylinder and the cylinder holders to slow down the heat transfer.

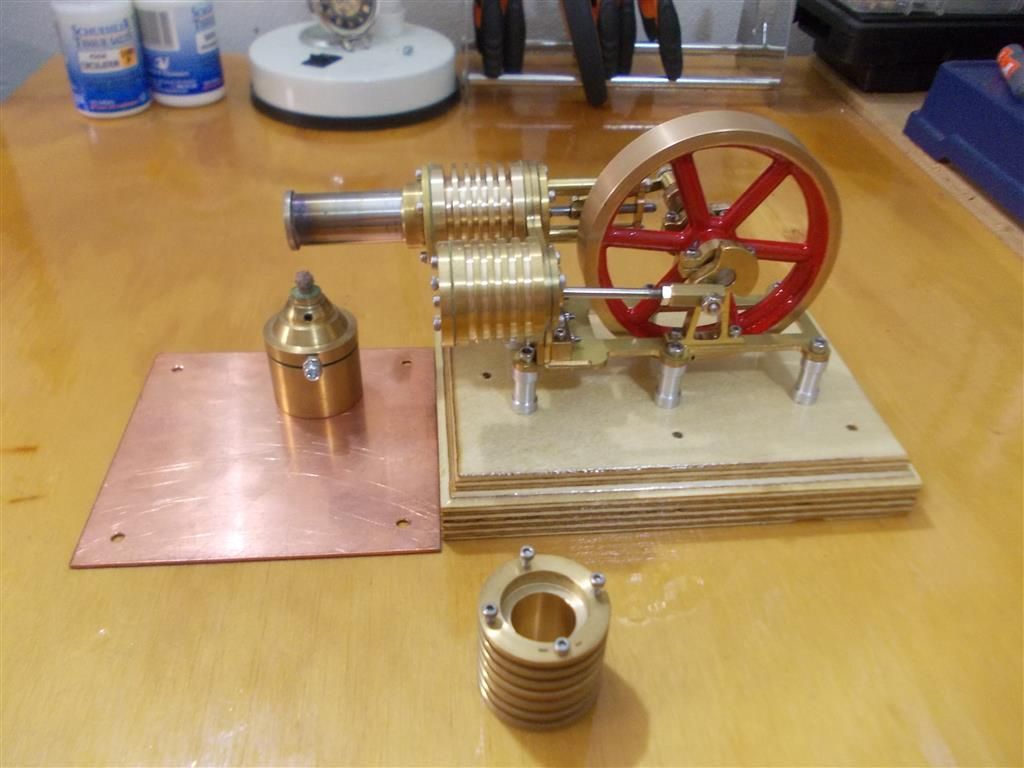

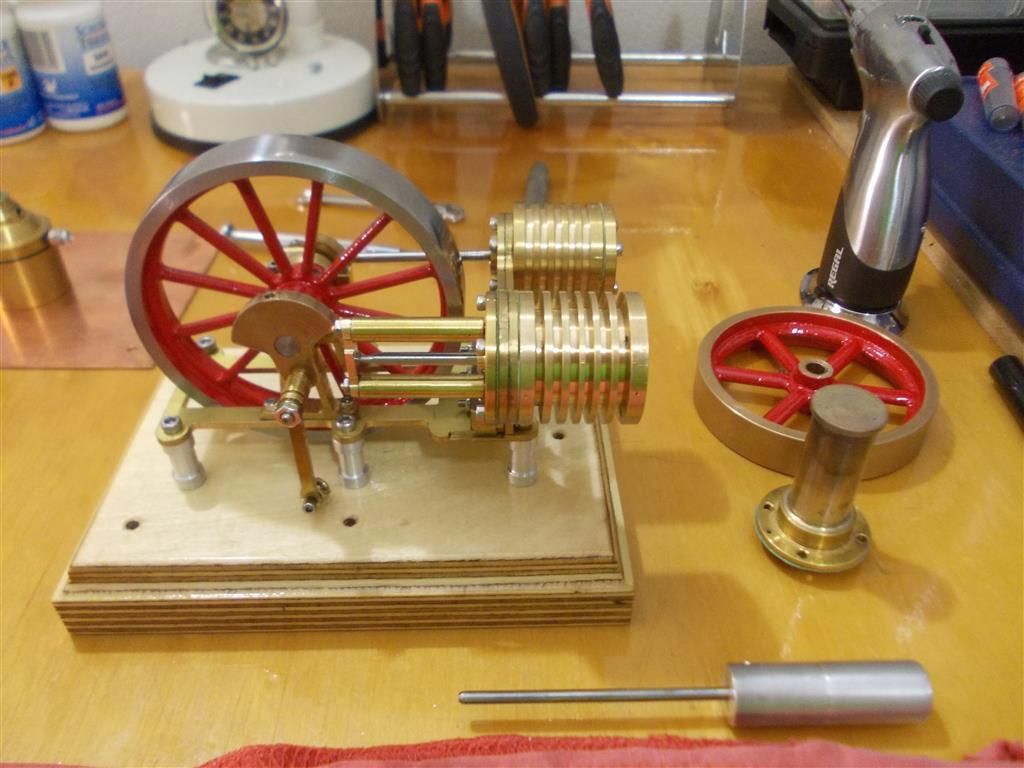

I have tried to keep all dimensions the same as the original glass version but I had to go with the stainless steel tube from Bunnings as the hot cap so things had to be modified slightly to accommodate this. See above for D. piston dimensions. Other than that everything is the same.

I have just realised that I did not enlarge the D. cylinder by an extra 1.6mm to allow for the larger piston diameter. I will do that tomorrow. That is plan A.

Ian : no the piston is not rubbing against the hot cap ; I am sure I would feel that. It is also a good close fit to the end of the hot cap. I may knock another 0.1mm of the diameter of the piston if nothing else works. That is plan B.

Plan C is to make the D. piston out of something other than aluminium.

NOTE ; the inside of the stainless steel tube is brown after all the heat today…almost like rust ! I am starting to suspect that it may not be stainless steel after all even though it was labelled as such. Perhaps stainless on the outside and something else inside ? It was stainless steel tubing from the laundry section of the hardware store.

Gordon Tarling.