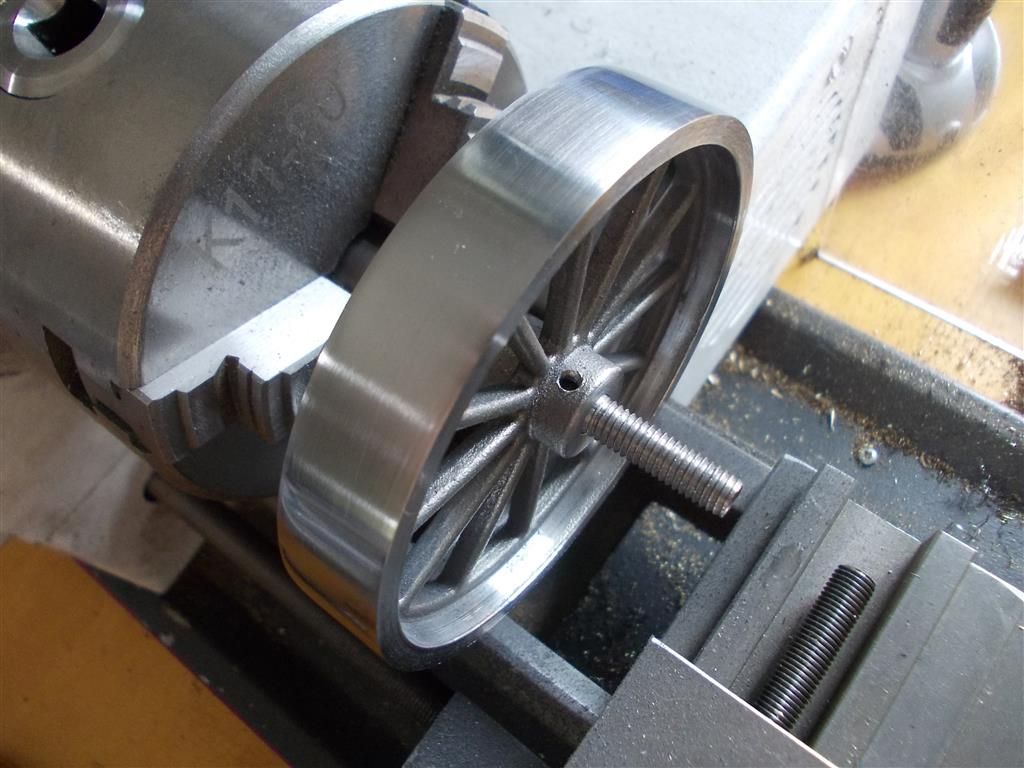

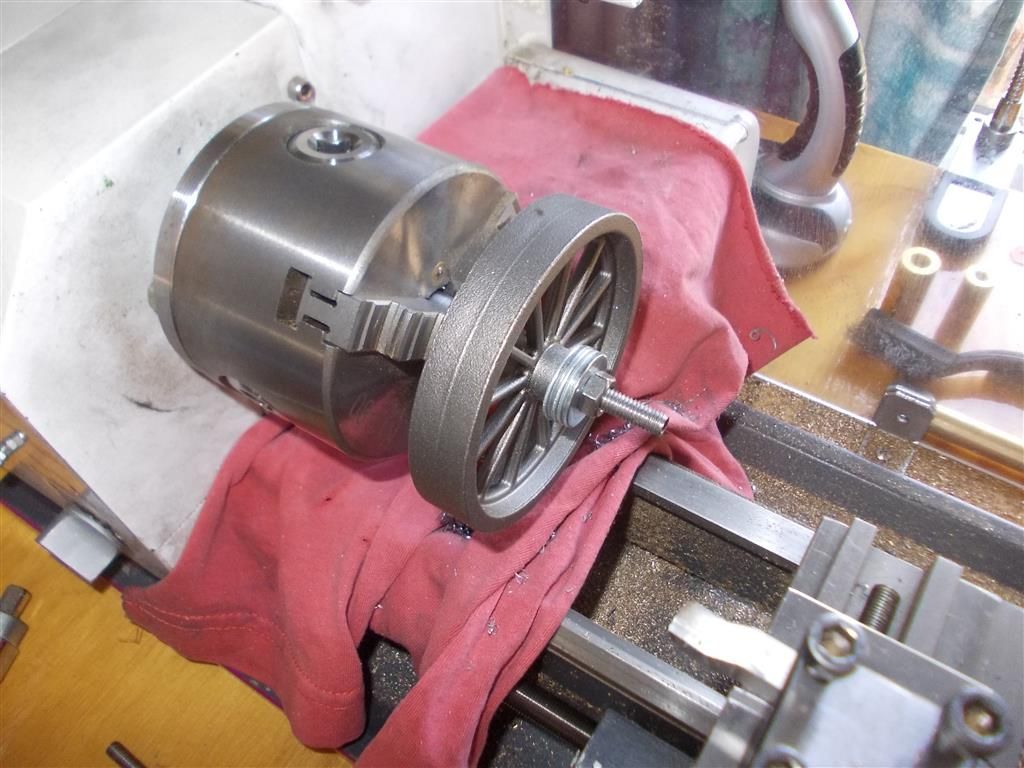

You could soon polish the flywheel up with emery cloth Brian. Maybe with a drop of oil to help stop it clogging up.

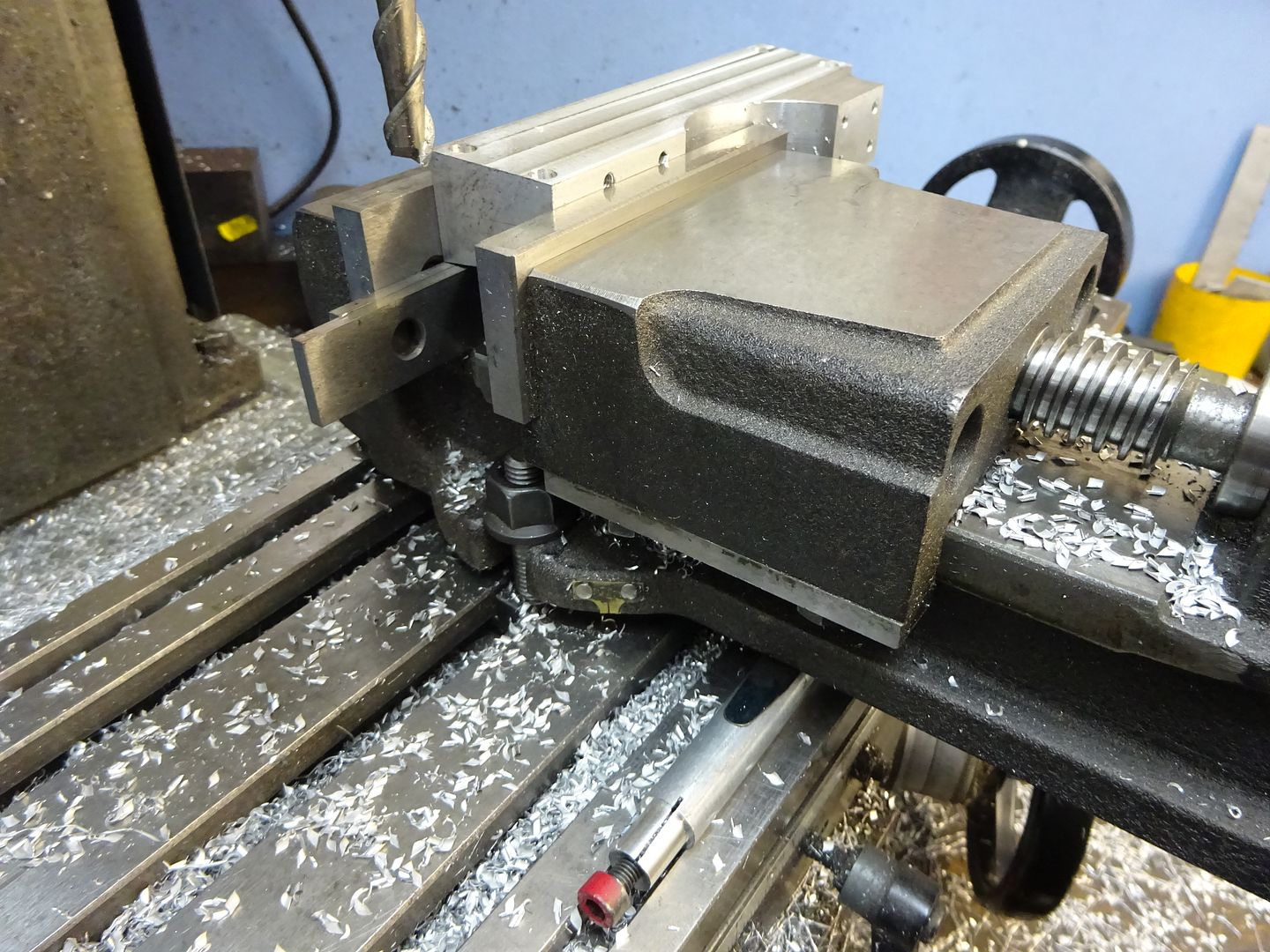

You'll probably need an extension drill for the grub screw hole. There are 2 ways of doing that. Face, centre drill some 1/4 dia mild steel, drill a hole and then loctite the drill in in it. Or use a pin chuck to hold the drill and fit that in the machine's chuck. These might need tightening with pliers.

When you figure out how to hold the flywheel at an angle don't angle it any more than you need because the drill will be inclined to skid on the surface. A centre punch mark at the angle the wheel is at will help but I'd be inclined to mark the surface with say a 1/4" dia drill as well before using the one for the tapped hole.

Holding it at an angle?? Saw the angle through a piece of wood leaving 2 pieces at the correct angle and clamp between those. Tilt the table if it will do that but the vice will need clamping that way.

A flexible drill vice is handy. I have one bought a long time ago that was made in India. It's similar to this one

**LINK**

Arc also do another range that is cheaper but they look to have gone pointlessly over the top with shapes machined into the jaws. All that is really needed is a ledge for plate, a horizontal V and a vertical one. People have used the one I have for milling and drilling things like lock plates. Ideally they should open to a bit more than the jaw width. Rotagrip sold an identical one but seem to have changed designs now. Oz – there are some similar one's on ebay including by  Optimum. Also some SG Iron ones.

Optimum. Also some SG Iron ones.

John

–

Edited By Ajohnw on 23/01/2016 11:00:40

Gordon Tarling.

I should not have tried to take a cleaning cut on the inside. It was quite tidy as cast and I only made things more difficult by trying to do this. I have machined enough brass and aluminium flywheels to know this by now ! I may end up painting the outside as well as the inside of the flywheel…perhaps black on the outer surfaces with red on the inside ? That will stop the rust. It is a lovely looking flywheel though ; I wish I could find something similar cast in brass.

I should not have tried to take a cleaning cut on the inside. It was quite tidy as cast and I only made things more difficult by trying to do this. I have machined enough brass and aluminium flywheels to know this by now ! I may end up painting the outside as well as the inside of the flywheel…perhaps black on the outer surfaces with red on the inside ? That will stop the rust. It is a lovely looking flywheel though ; I wish I could find something similar cast in brass.

The lads said help yourself. Actually I don't think the stuff I have ever wears out, it just clogs.

The lads said help yourself. Actually I don't think the stuff I have ever wears out, it just clogs.