Citric would take a very long time. I use Feb Brick Cleaner which is Hydrocloric solution. If used neat the scale will have just dropped off in about 1/2hr and left a grey surface. I then rince in water, dry and spray with WD40 as like a shot blasted surface the clean metal will want to start rusting. Also very good for cleaning steel and brass/bronze after silver soldering and takes HT5 flux off easily.

Use it outside and preferably store outside the workshop as fumes will make things rust.

This is a bit of 10×200 black flat bar after cleaning and no trace of scale

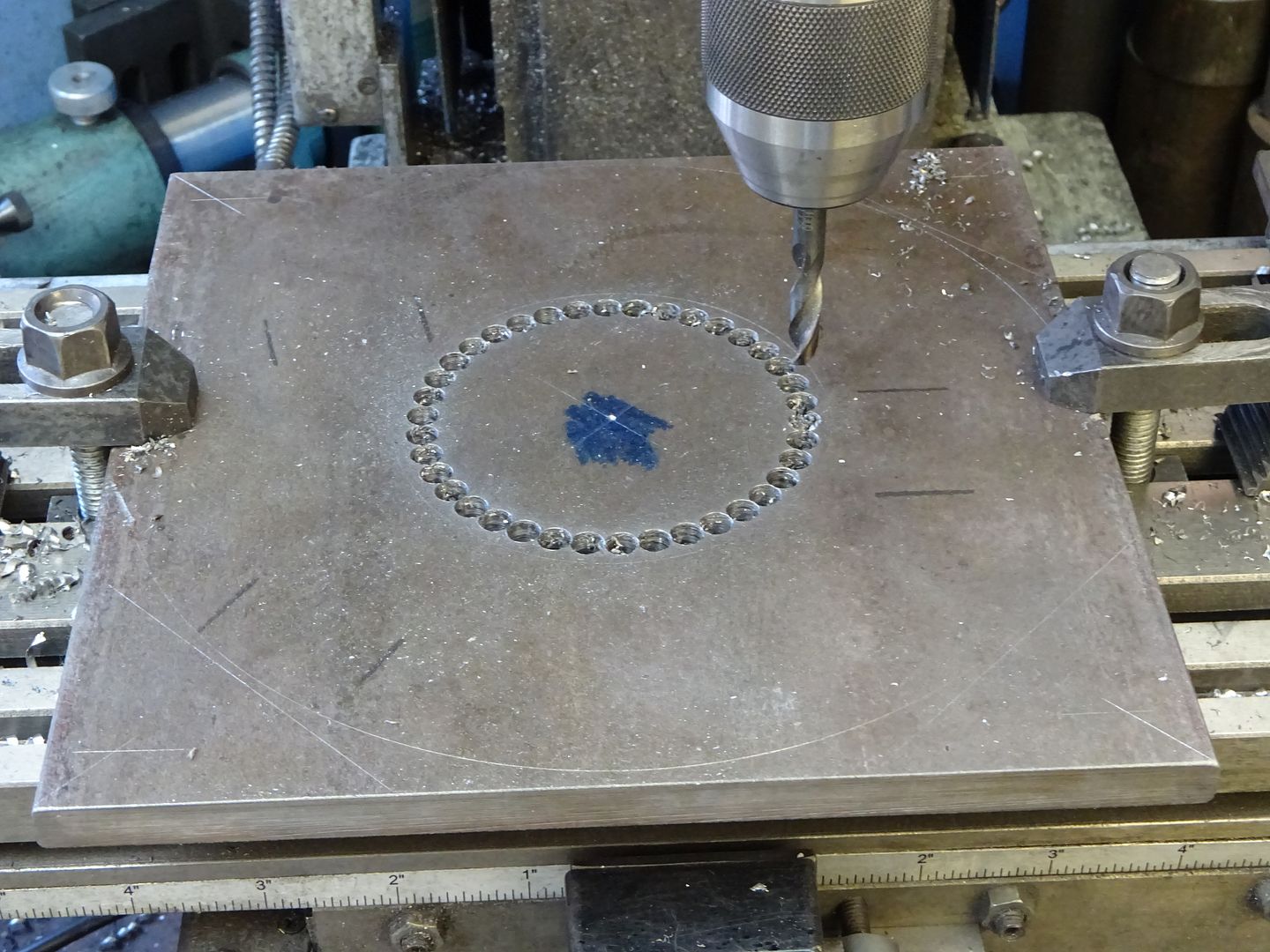

Our old friend JS posted about this, he used to produce dividing plates in batches of 50 or so if he did not pickle them his drills did not last very long.

Carbide should fair a bit better than HSS but it will not last as long as if it did not have to cut through the scale, your shallow cuts would really not have helped with cutter life hear as the first one would just be rubbing against the scale and then you have lost the edge for the rest of teh job.

richardandtracy.