Jens – Do not be put off by the thread above. Have a go but be aware

1. Small turbines are greedy for steam. Successful units tend to use waste steam.

2. Small turbines are FAST. I had one go up to 2 million RPM before it disintegrated. The aircraft Gyros run at about 14-16,000 rpm. They run in a partial vacuum because the air is sucked into them, but NO power is taken from them (except overcoming friction).

3. Their efficiency is abysmal. I was after power output.

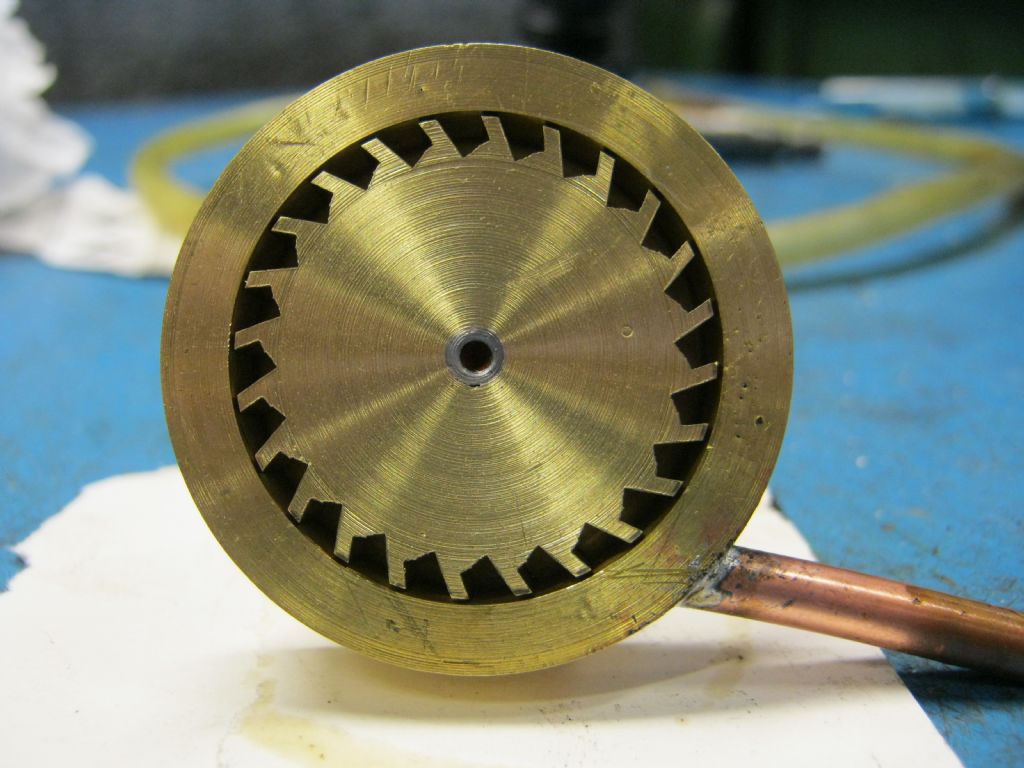

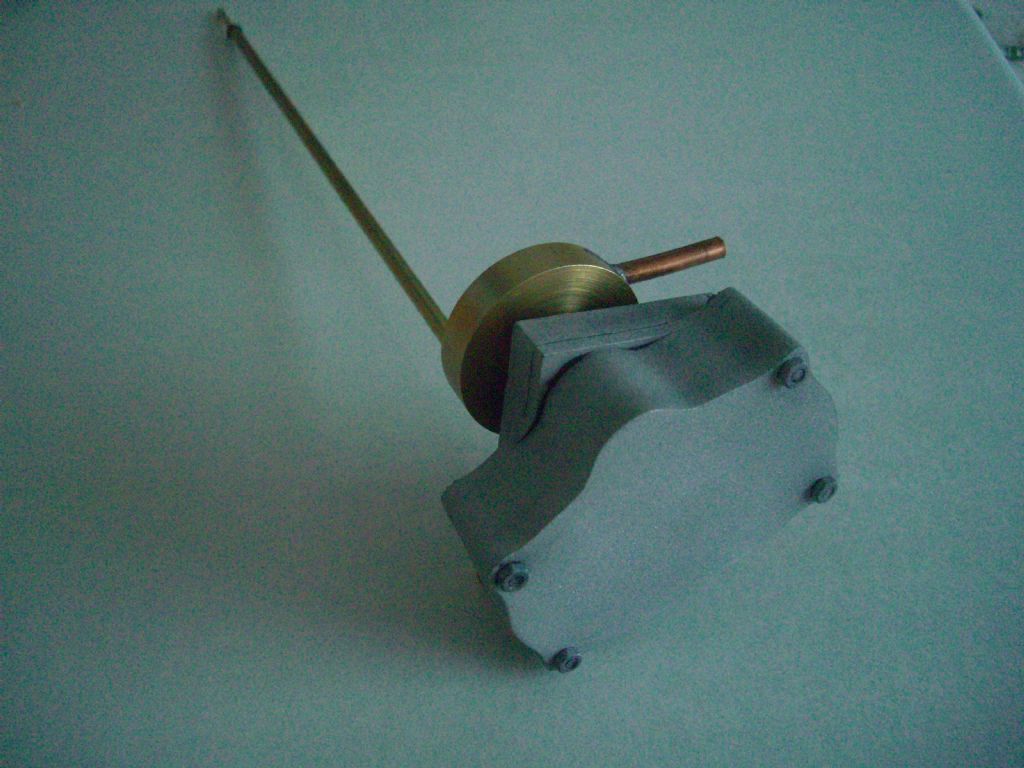

4. Both Stumphs and DeLavals are not so difficult to make if you make the correct tooling.

5. You will have 3 or 4 BIG problems

a. Bearings, you will ‘fry/curry’ them by the dozen, But things have moved on in the past 20 years,

b. Reduction gears – I often got the dreaded ‘Grrrrr-wheee-poof’. As the gear stripped, the turbine ran away and disintegrated!.

c. The physical strength of the turbine wheel. Calculate the internal stresses on your wheel at 2,000 rpm, 20,000 rpm, 200,000 rpm and finally at 2,000,000 rpm. It is horrendous.

d. Nozzle design. In these sizes remember you are well down into the boundary layer.

6. Beware there are many claims and conspiracy theories about Tessla’s turbines and the rest of his works BUT that is enough of that.

Go for reaction turbines, I did try an expansion turbine, a lot of work and I could not get it to spin. I did but the clearances were too large.

I am afraid my note books vanished some years ago

If you succeed please write it up. Turbines are such simple machines and well worth working on. I will watch this space for signs of success.

Good luck

Dick

Clive Hartland.

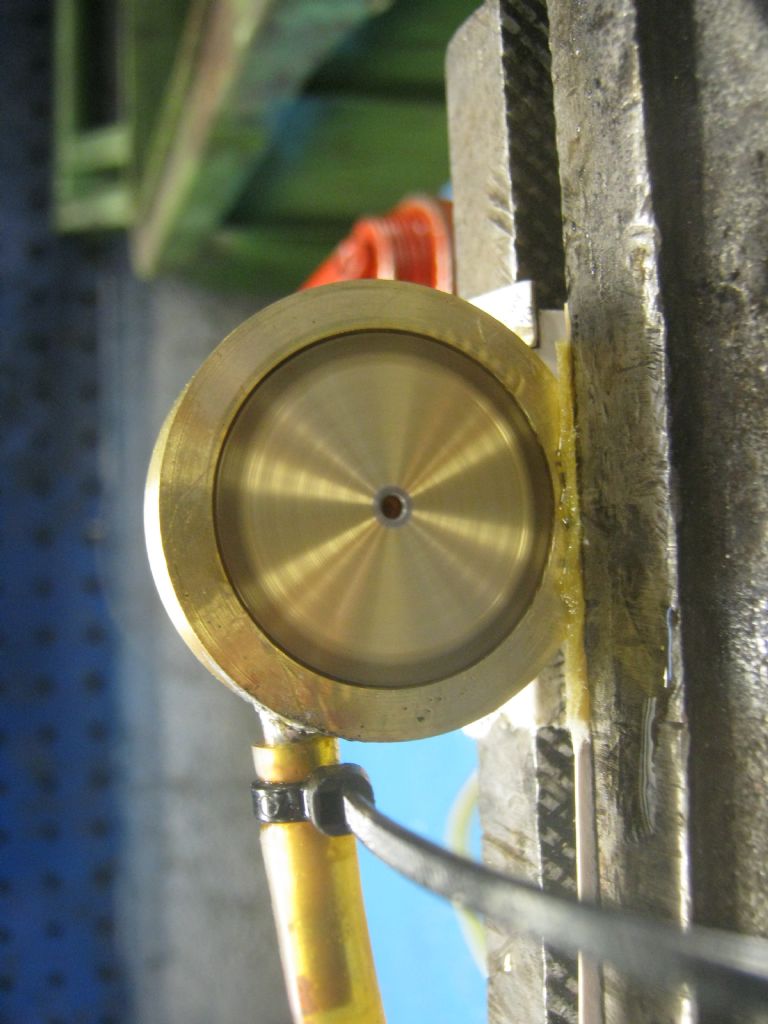

No problem with ball bearing with diesel oil, no mixed with water. The turbine ran above 35000 rpm with good torque. When i removed the heat of the boiler, the steam turbine was still running up to 2 minutes before the pressure was dropped of.. there was enough torque.

No problem with ball bearing with diesel oil, no mixed with water. The turbine ran above 35000 rpm with good torque. When i removed the heat of the boiler, the steam turbine was still running up to 2 minutes before the pressure was dropped of.. there was enough torque.