Small turbines ‘Oi-vay’!. You would get more power out of a small oscillating steam engine that out of a small turbine. I have heard a lot of reasons for the low efficiency of these little brutes. But I am still not convinced.

In the mid to late ‘80 I had a lot of correspondence with the late Prof Chaddock on this subject. A few years ago I tried to get help with a letter to the editor Model Engineer.

The problems you will have are

A. The bearings – they tend to ‘fry’ I tried all sorts even old battery electrodes!

B. The gearing – most wheels seem to need the attention of a good dentist after a few minutes.

C. Balance – Prof Chaddock wrote to me and said that he had to get the centre of rotation within 0.000002” the centre of mass. He did this with two razor edges some ‘bluetak’ and a small scraper.

D. Low power output – it is abysmal I used to test run mine using a magnet and a coil connected to an old oscilloscope. I could hear the speed fall off when I connected them together.

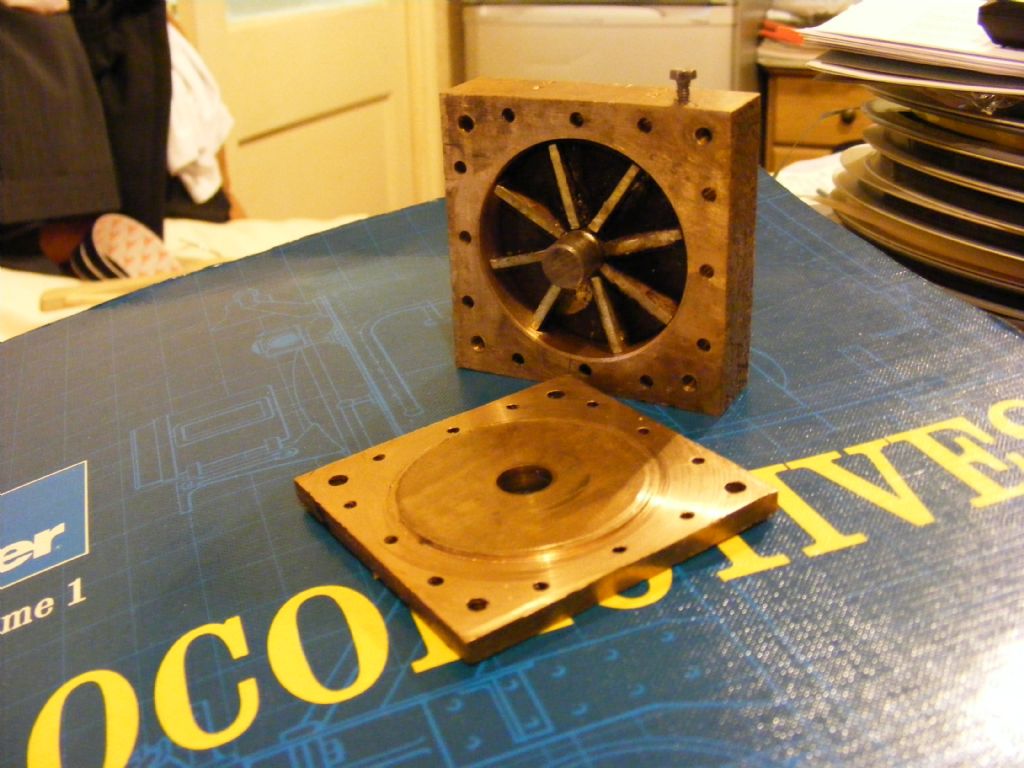

E. The turbine wheels I tried: DeLavals, Stumphs, and once as an absolute masochist a three stage Curtis Stumpf wheels are the easiest to make with a little cone shaped end mill. DeLavals you can make in two stages. Stage 1 gash your wheel. Stage 2 make a small hollow thin walled saw edged cutter to cut the ‘inner’ side of the blades. I did not worry about the outer side of the blade. Sometimes I just gashed the wheel, shaping them made little difference.

F. Test them on a stout bunker. I used to disintegrate 75 to 85% of them.

G. Have 50 times more steam available than you think you will need. Then treble that amount. Small Turbines are GREEDY. At low speeds they drink it and at high speeds they consume it as if it was going out of fashion!

Tessla turbines: I made one. To get it to run the turbine was made a push fit into its casing at normal temperatures. As things warmed up it would expand and it would turn. I only once got it to run at nearly ‘full chat’ and the plates distorted at about 90,000 rpm!.

I used a flash steam boiler made of 3/8” diameter about 18 foot long mild steel tube heated by 3 large propane burners I borrowed from a roofer. I found I could light a cigarette of the turbine input pipe.

I spent about 6 years on the project and got nowhere!

Finally remember that the speed of sound (in air) increases by about 0.6 M/S per degree C. So be careful when folk talk about steam flow being supersonic it often is not.

KWIL.