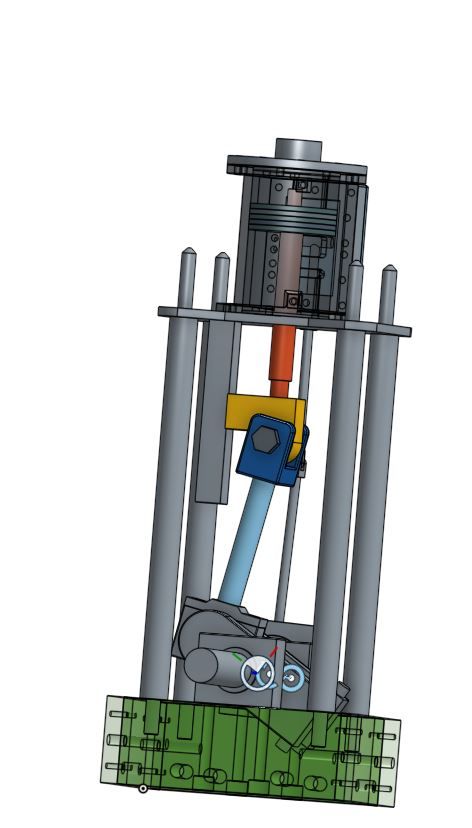

I promised pictures. This one has been a B**CH (Language moderated due to innocent bystanders…).

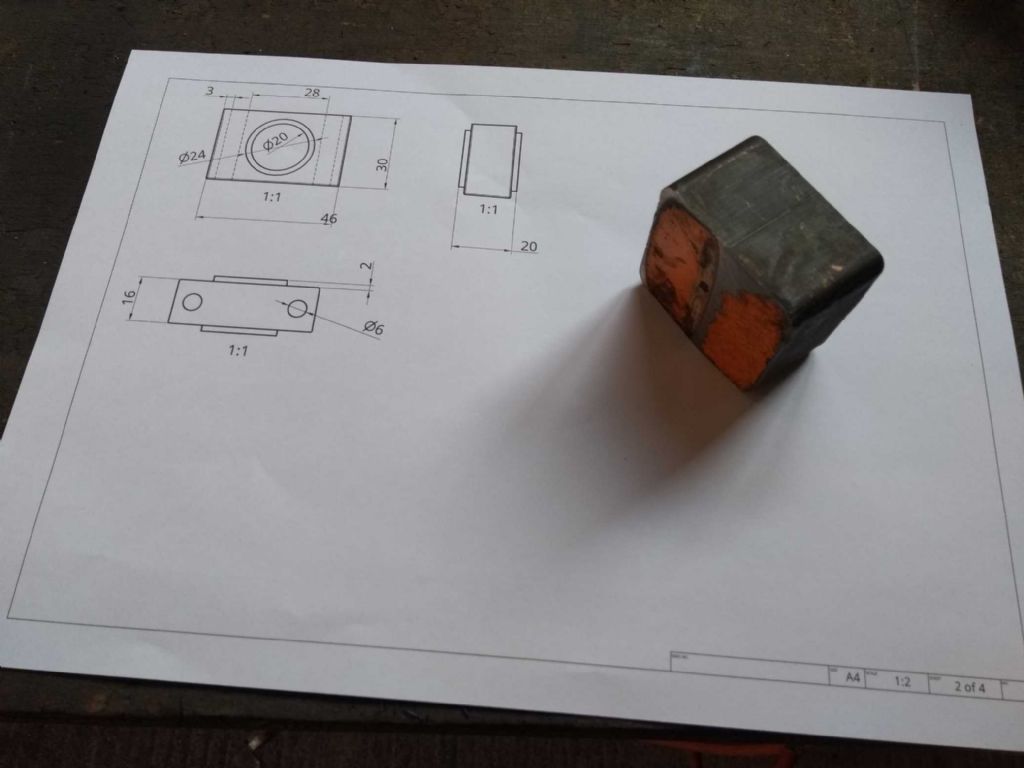

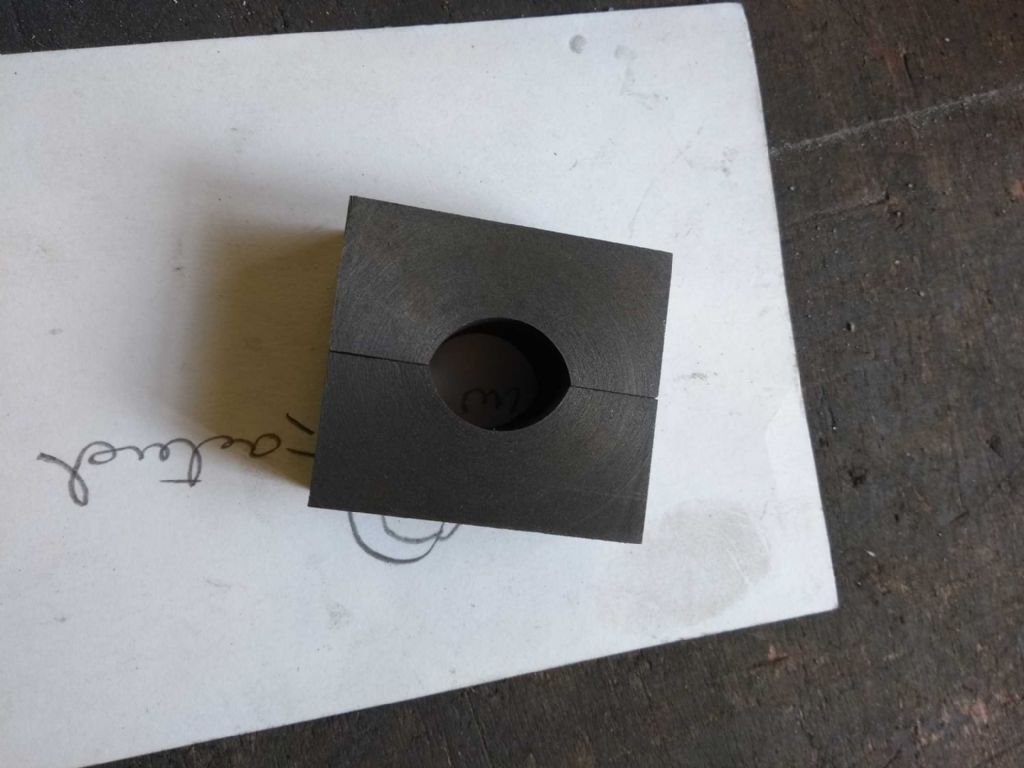

I started off with good intentions and a nice bit of cast.

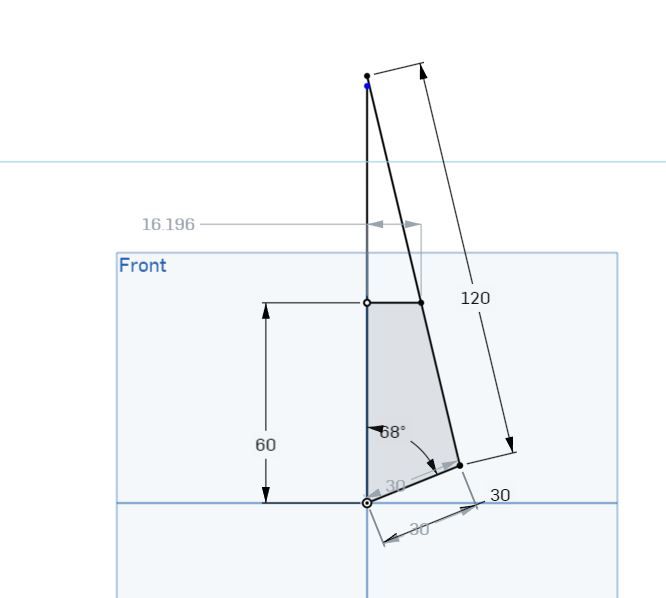

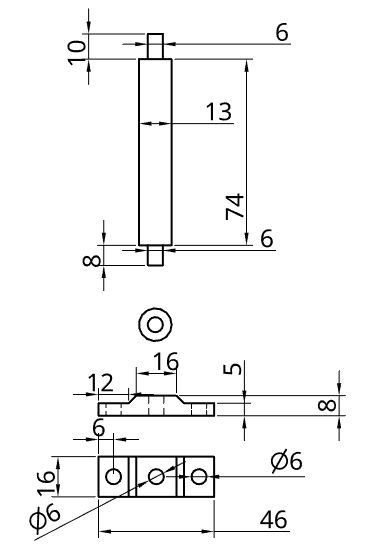

The plan conveniently in the photo.

The first thing I did wrong was to trim too much off. I was using the mill to reduce the height by 5mm or so. (1 inch to 20mm). I was taking about 3 mm deep cuts but .5 – 1mm deep if that makes sense. I was (or thought I was) keeping an eye (and a hand) on the Z axis dial mainly as the poor mill was juddering a bit and the dial tended to drift. Despite this it some how cut 4mm deeper at the back than the front.

This one was definitely 'bad workman'! I decided that this wasn't going to work, so reserved if for practice (for the valve face) and bought another bit.

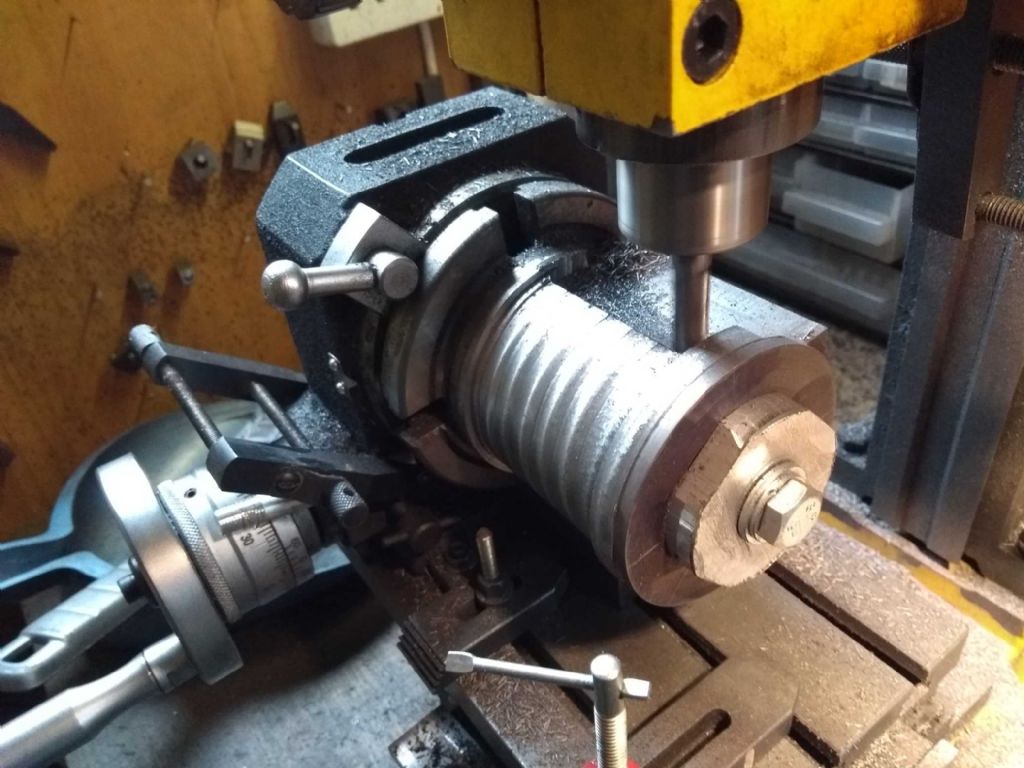

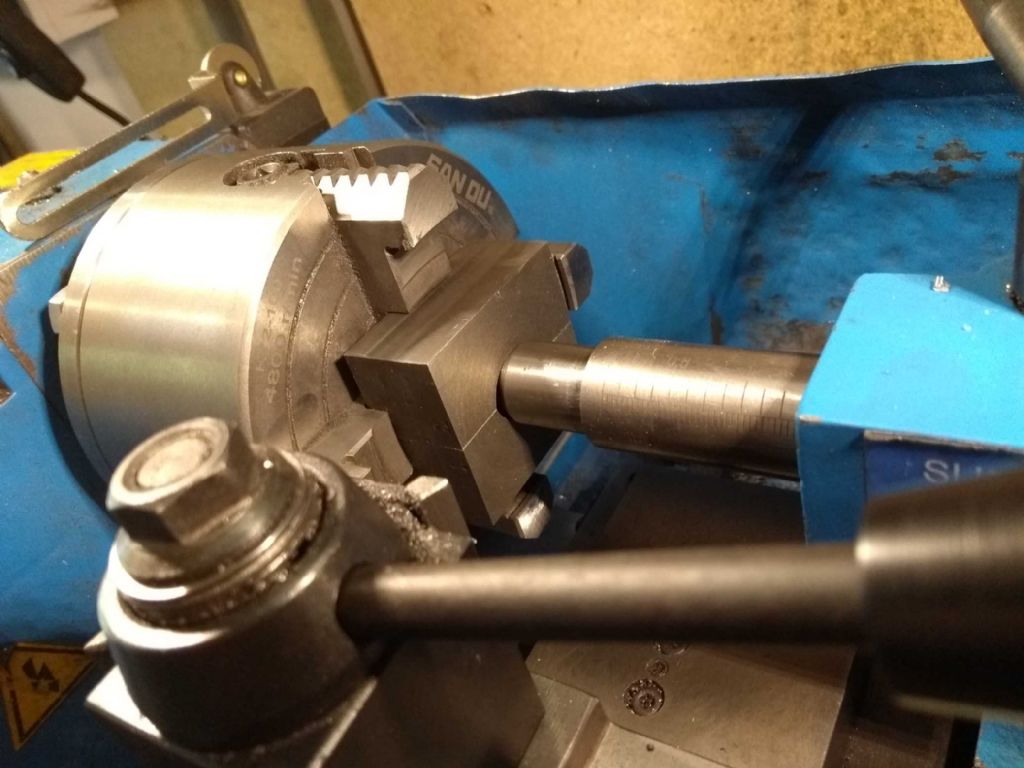

This time I took it down near size on the lathe which worked better. Sliced it in two with a slitting saw as below.

That went quite well, though I ended up changing the clamping mechanism as the clamps stuck out to much into the barrel of the saw.

Happy, happy!

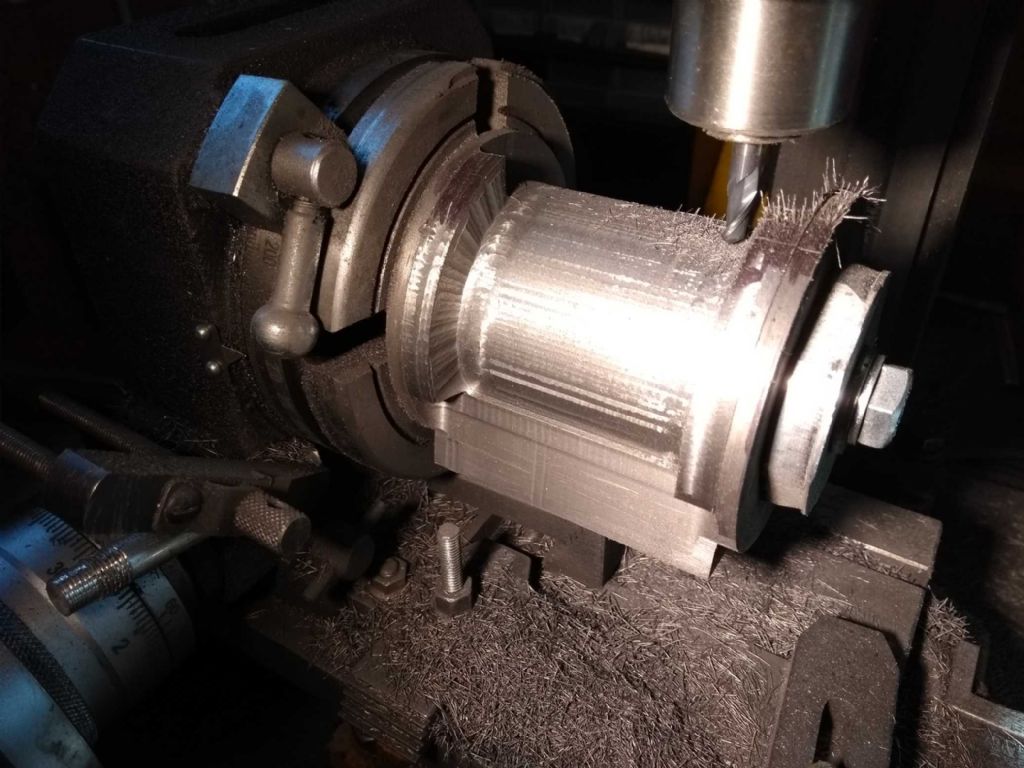

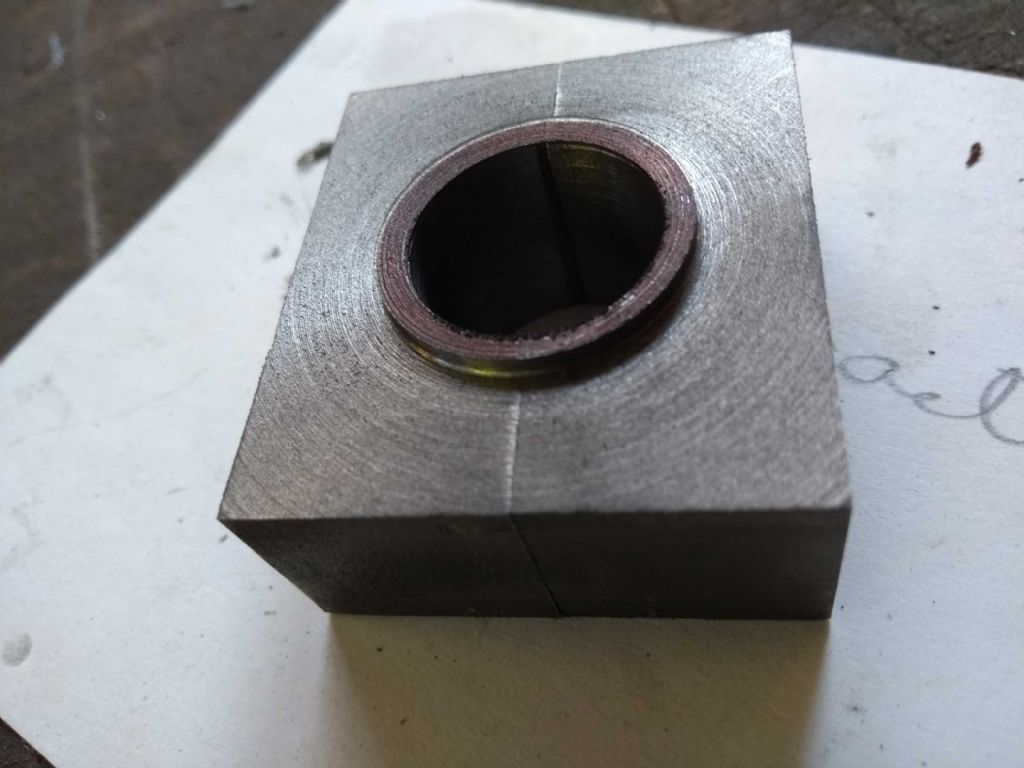

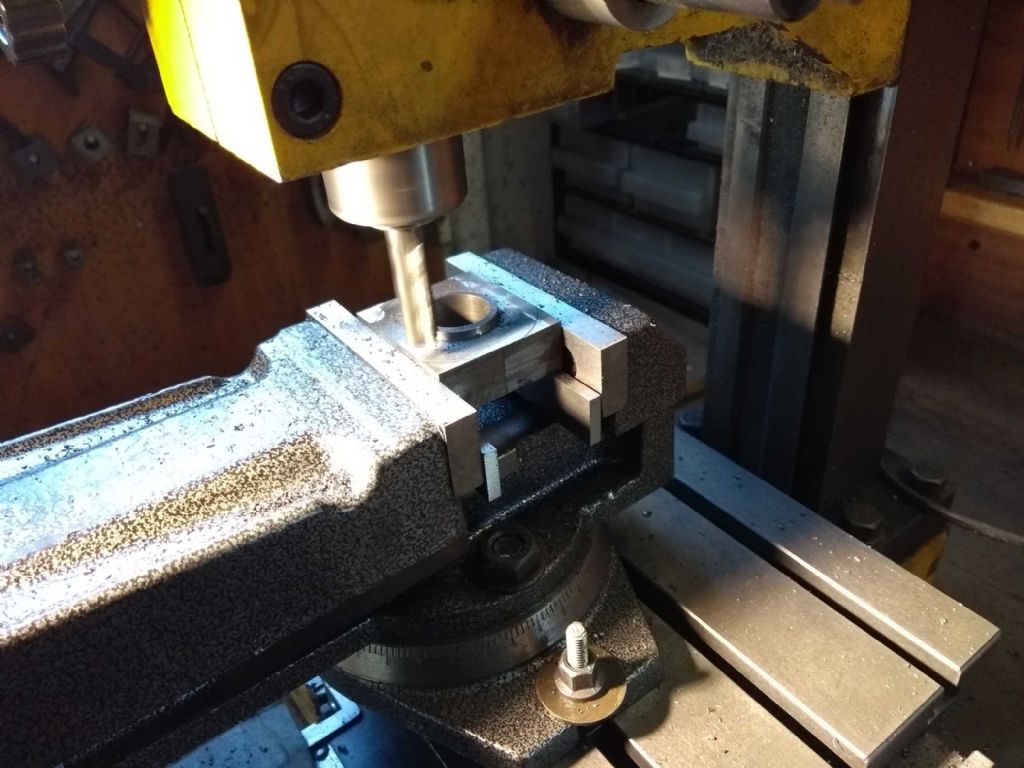

Then on to drilling out and boring.

That seemed to go OK, but I managed to cut it 0.4mm over (see early post passing responsibility off onto my tools!).

All seemed lost until the kind Mr. Ballamy suggested I split, thin and retry.

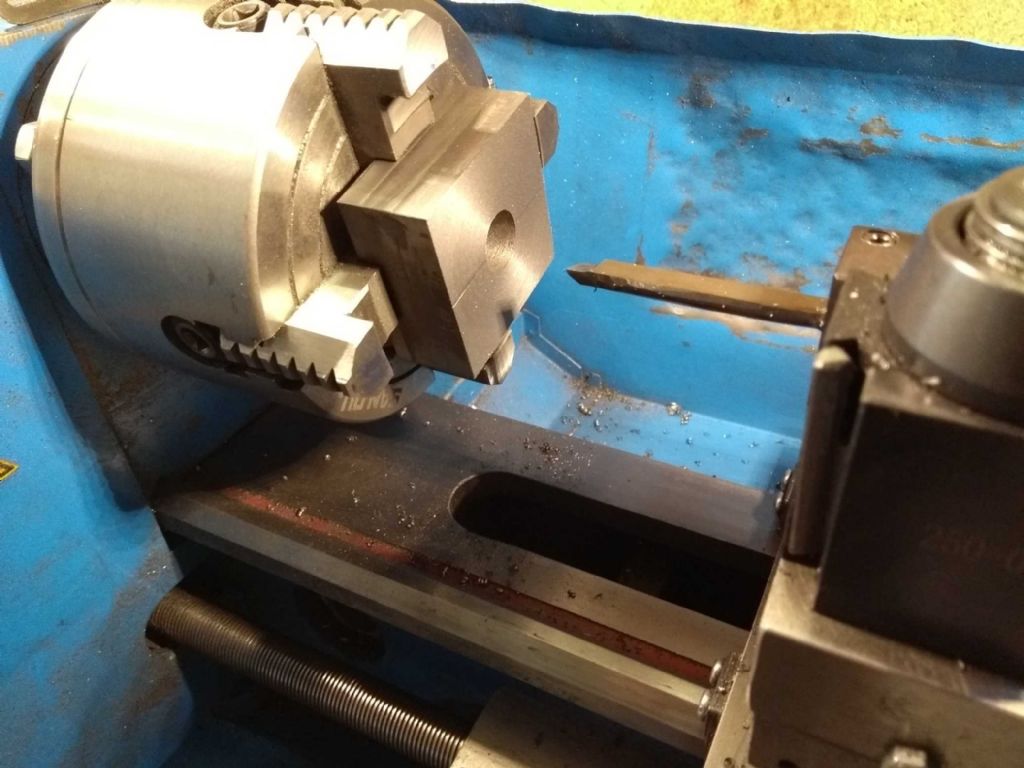

The thing I was worried about was centering, but in the end I just used the centre from the tailpost as here.

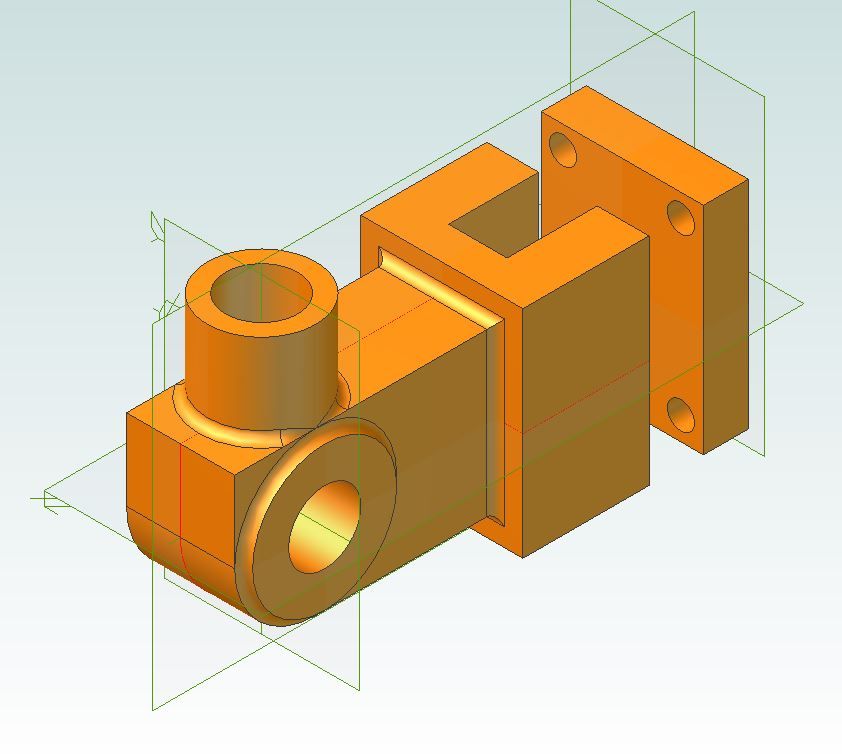

And added the sticky up bit (sorry, I don't know the correct engineering term – but this…)

Then my troubles really began!

I found it (nearly) impossible to mount the block in the 4 jaw and get it centred. In confession, I am TERRIBLE at centring in the 4 jaw. I seem to get the rough adjustment with the chalk circle OK, but then it all goes to pot with the clock and I have to go back to the chalk circle again.

In this case matters were made worse as the block was getting gouges in where I tightened up too much. This made adjustments in the other access difficult, with the jaws dug in. I tried some hard shims, but I was getting nowhere (about 2 hours of nowhere by now!). Then I noticed that when I tightened the jaws (I mean reasonably firm not tight tight), the block was moving- moving away from the chuck face.

So each time I moved it to correct a clocking error it was adding another error due to the movement. I have no idea why this is except perhaps it was a fairly low hold with an 'amateurs' vice.

I gave up.

I then had the marvellous idea of trying to hold the 2mm stub in the 3 jaw (the bit I don't know the name for). I thought this probably wouldn't work and I was right. the minute the tool touched the surface, 'Spung!', it jumped off the chuck.

I thought of mounting it on the faceplate or making a stub mandrill, but all of those required quite a bit of work (I have no suitable clamps for the faceplate, though a mandrill could have been possible.

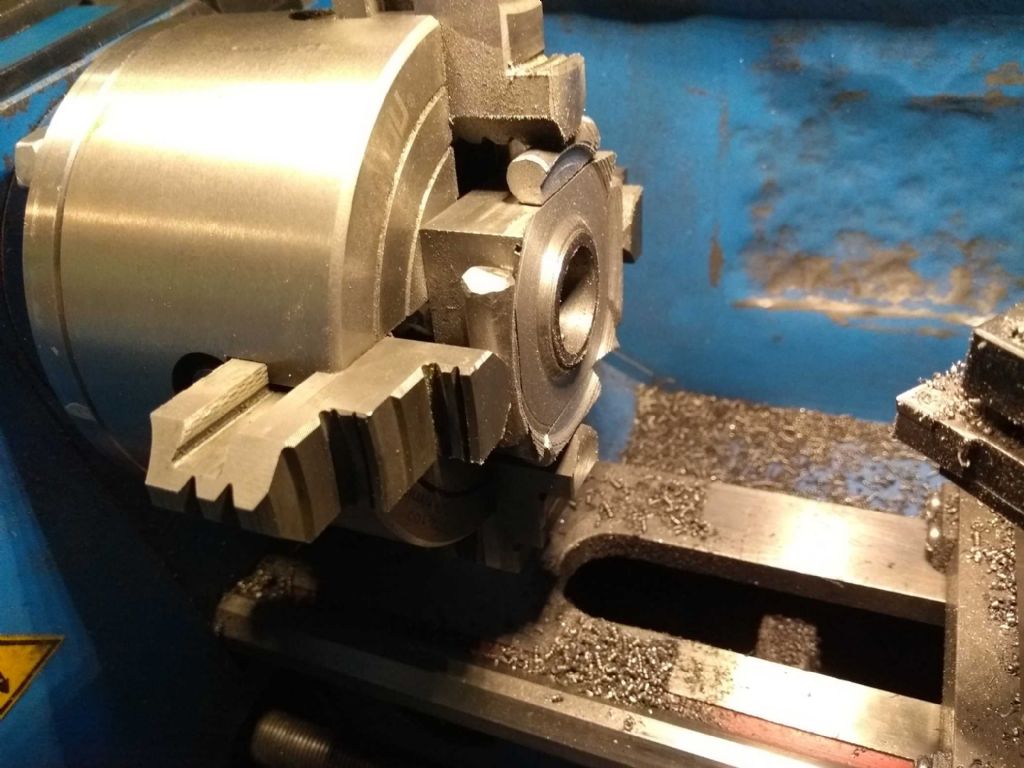

On the verge of packing in for the day and going to take consolation with my friend Vin (Vin Rouge that is), I thought of turning the 4 jaw chucks jaws round to give me a higher grip.

This worked better than I deserved as it turns out the centre hole in the chuck is almost exactly the diameter of my sticky out bit!

The jaw height closely matched the bearing height so I needed add some separators to give me space to get in and cut. Even then I struggled to get the tool in and couldn't cut to the edges.

I tool cuts to get to the right depth with the (carbide) tool at an angle and then straightened it out to make the outside of the sticky out but vertical.

Finally, I took it to the mill and smoothed off the corners that were sticking up.

Final step with this damned thing is to trim it..

Iain

Andy_G.

Andy_G.

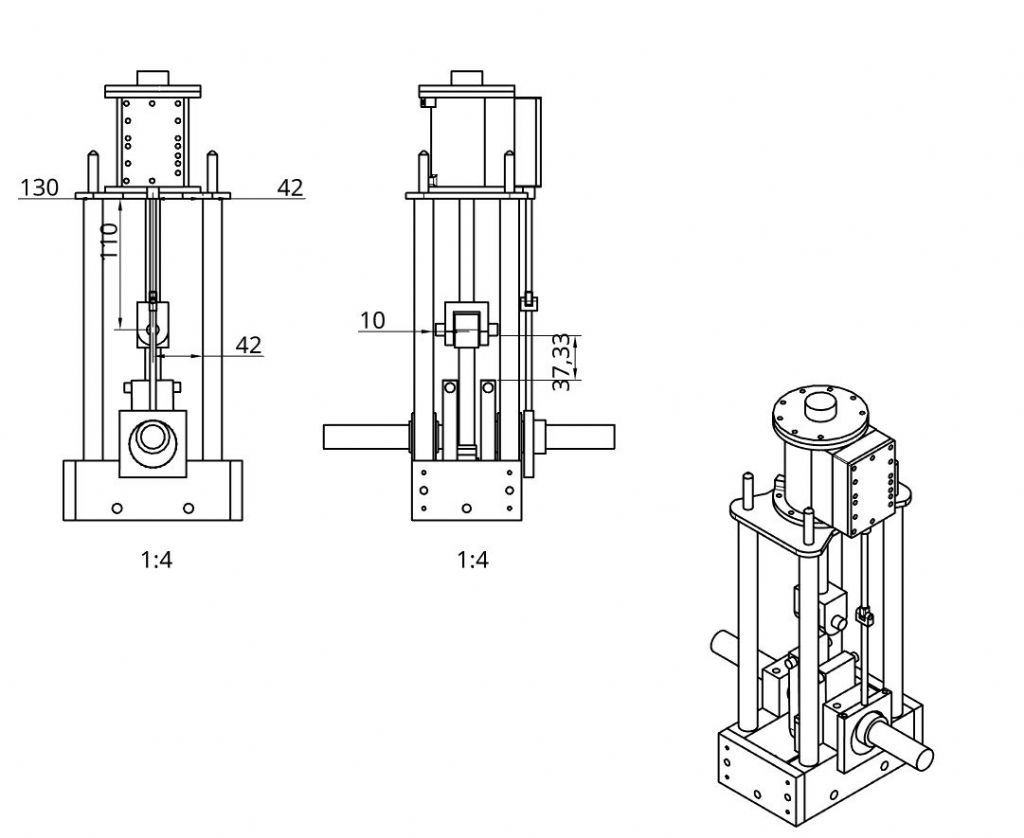

.

.

.

.