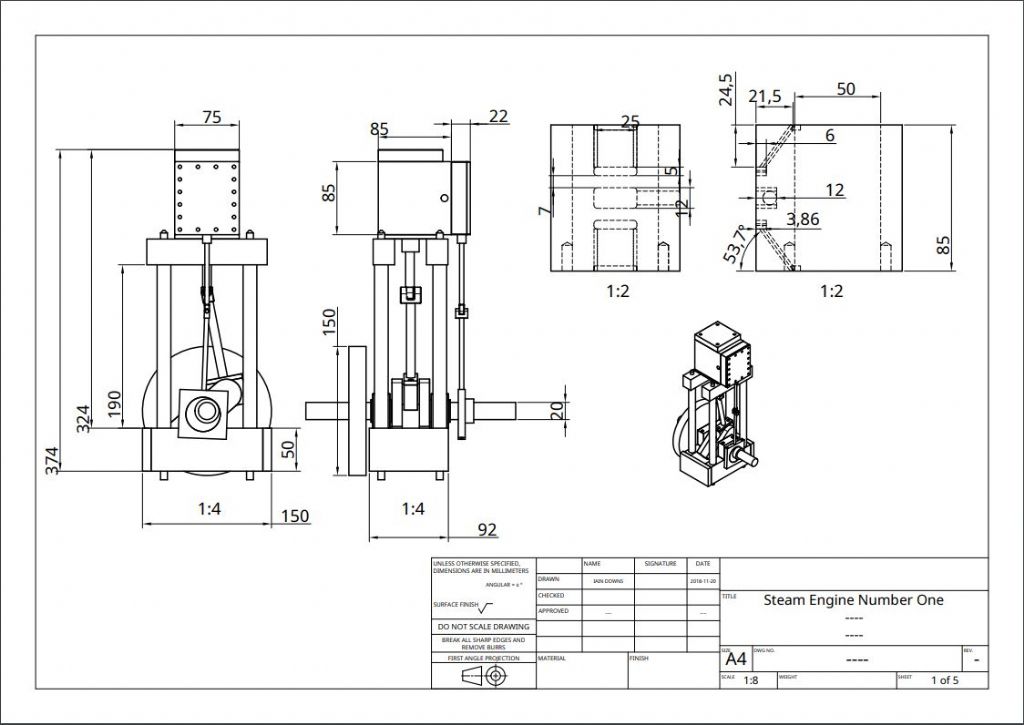

Build Plan

Here's what I have in mind at the moment. What I've worked out so far, anyway.

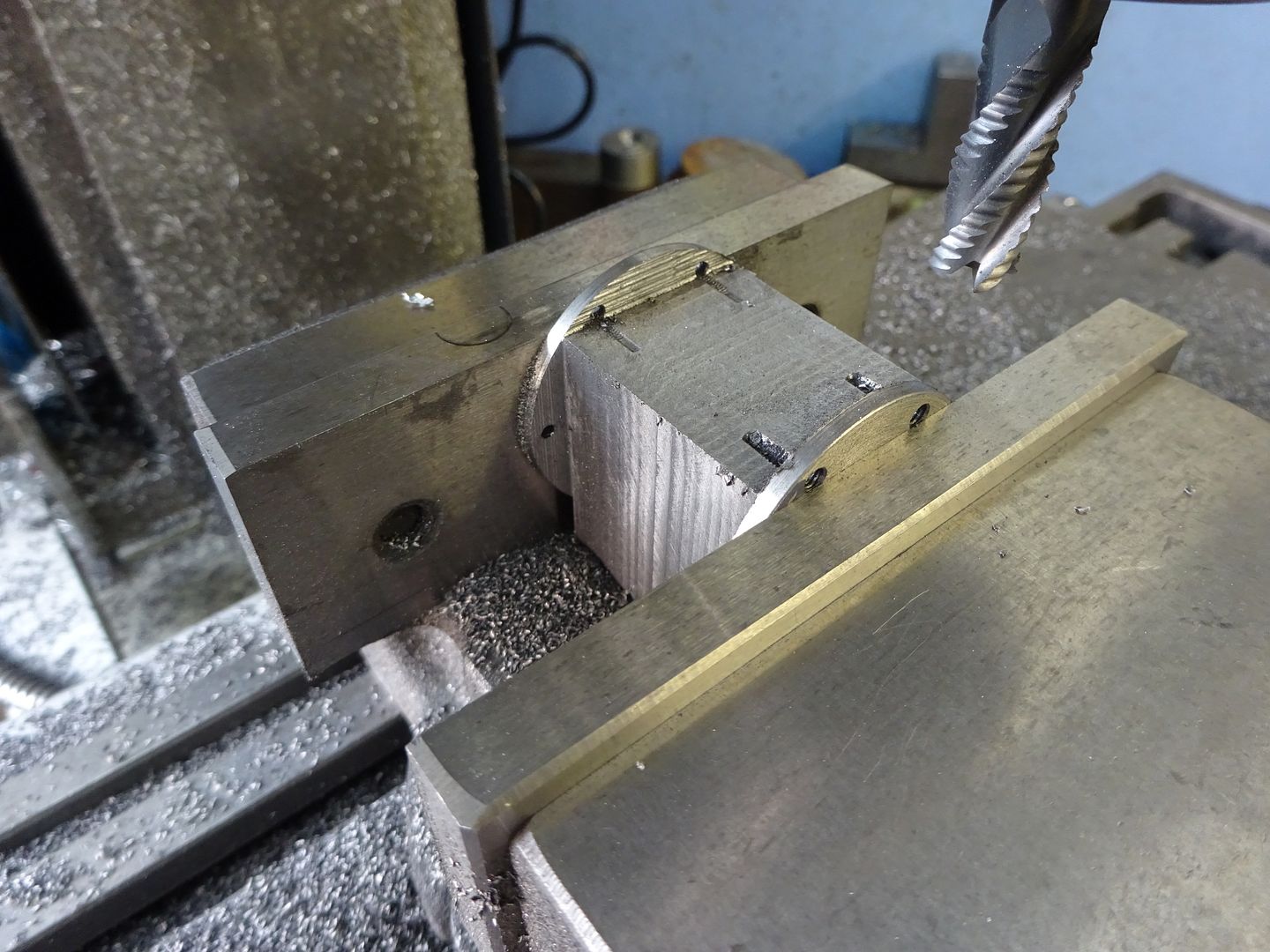

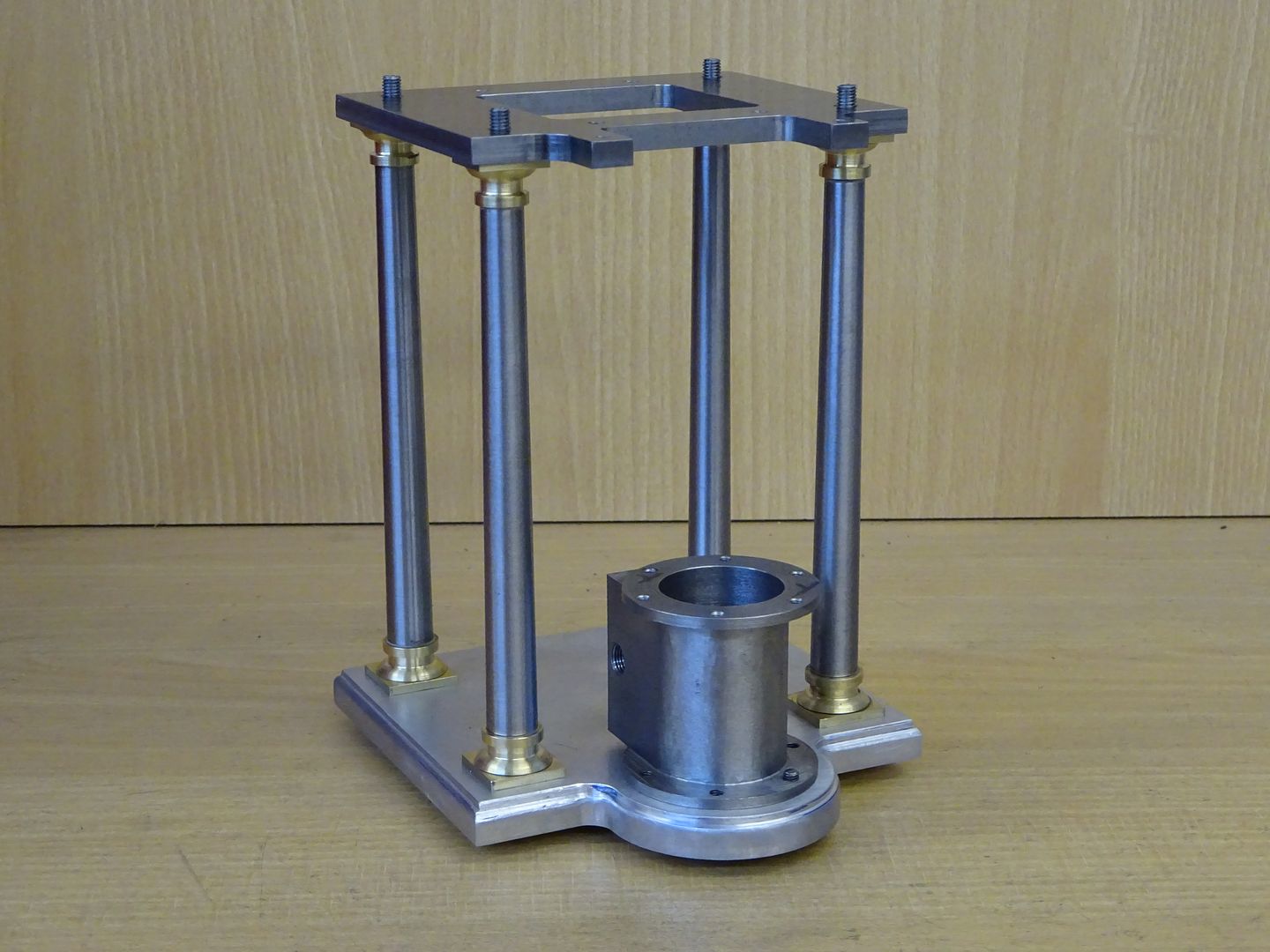

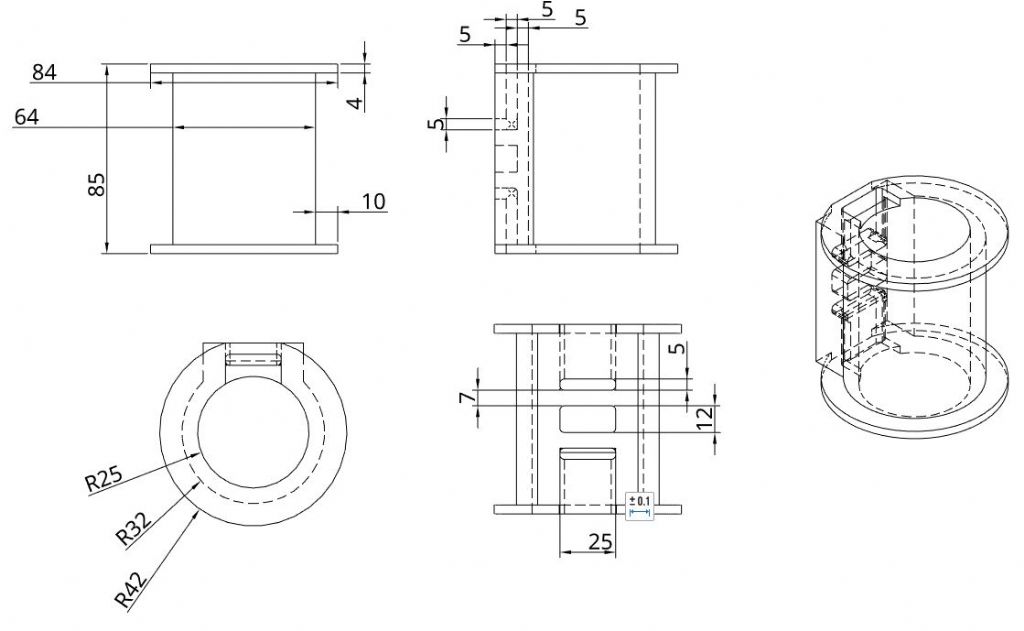

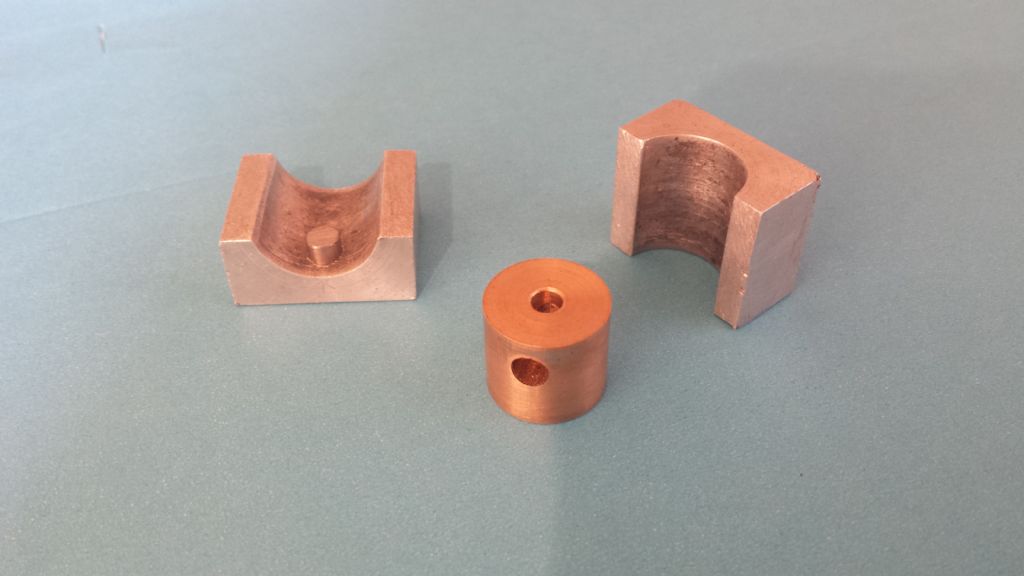

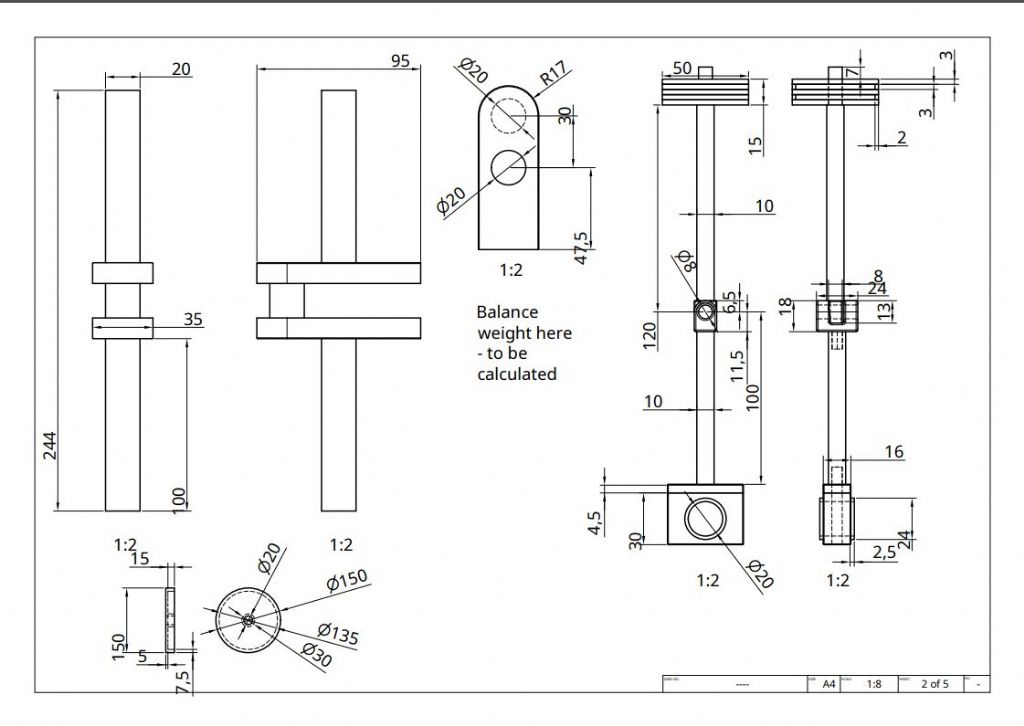

Crankshaft, Crank Case and Main Bearings

Shaft 20mm Silver Steel, Journals 12×35 mild steel. Fix shaft with Loctite 638, pin through with (4mm?) steel.

Bearings cast iron, split pair, split in two and loctite together, bore to 20mm and heat to release (4 parts).

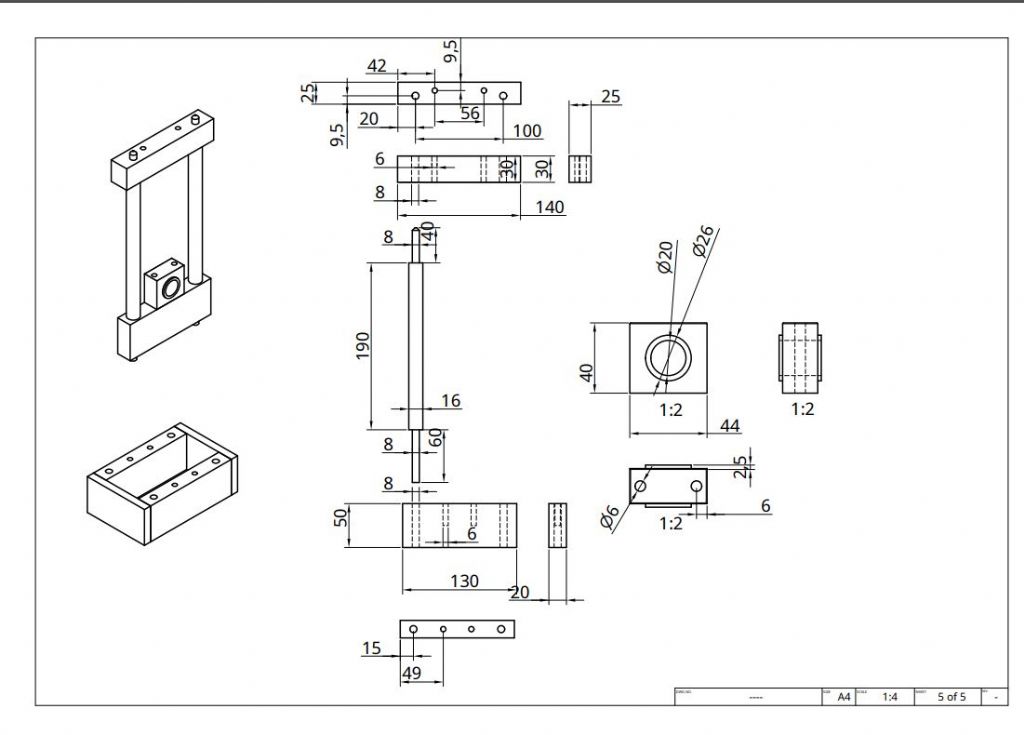

Frame Mild steel (squared and milled to size already!) bolted together. bearings set in place and lapped to a running fit with a spare bit of silver steel.

I intend to bolt a counterweight to the flat end of the journal but I've not worked out size and shape yet. It will involve integration  .

.

The drawings don't show oil channels for bearings, but I will add those in.

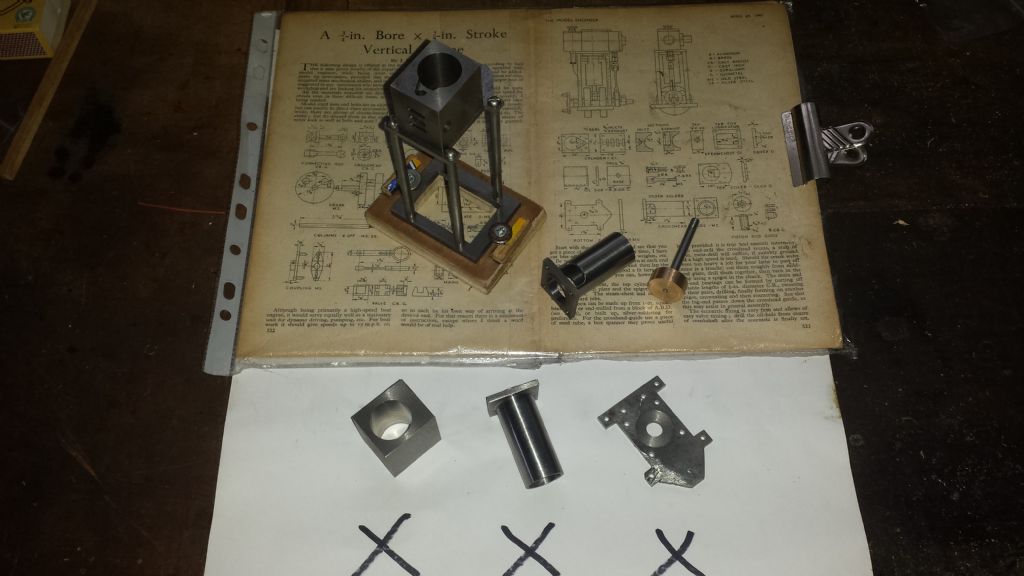

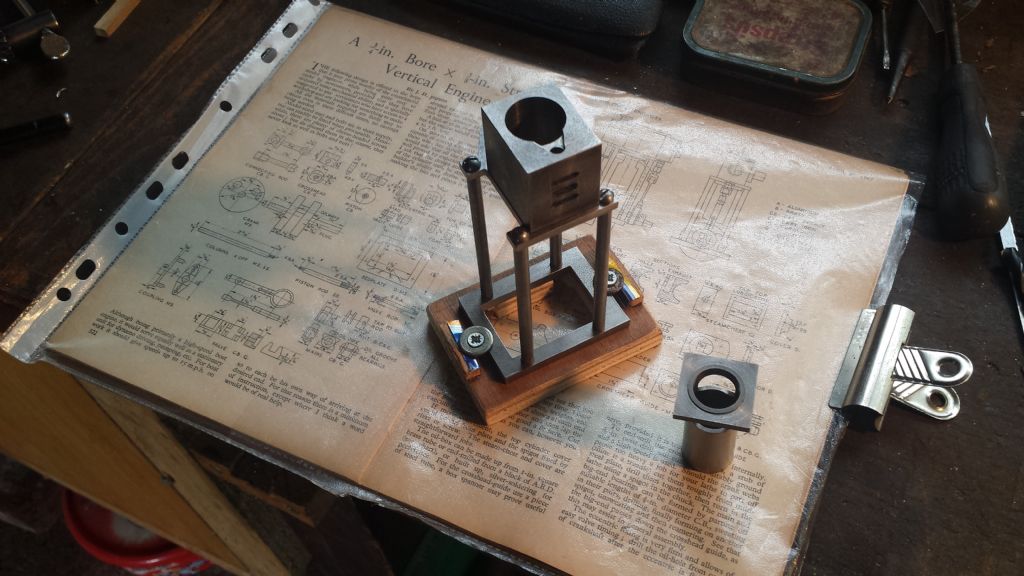

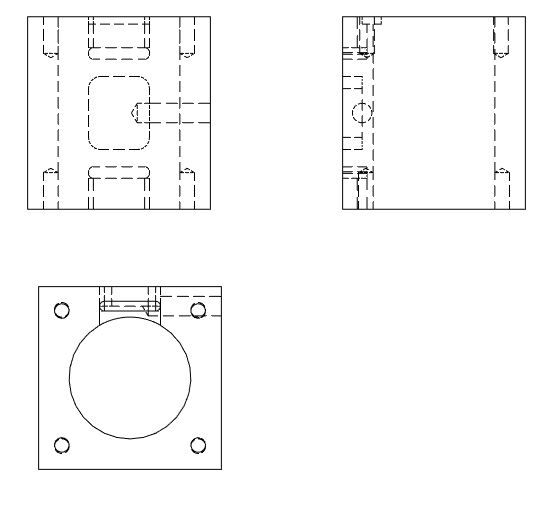

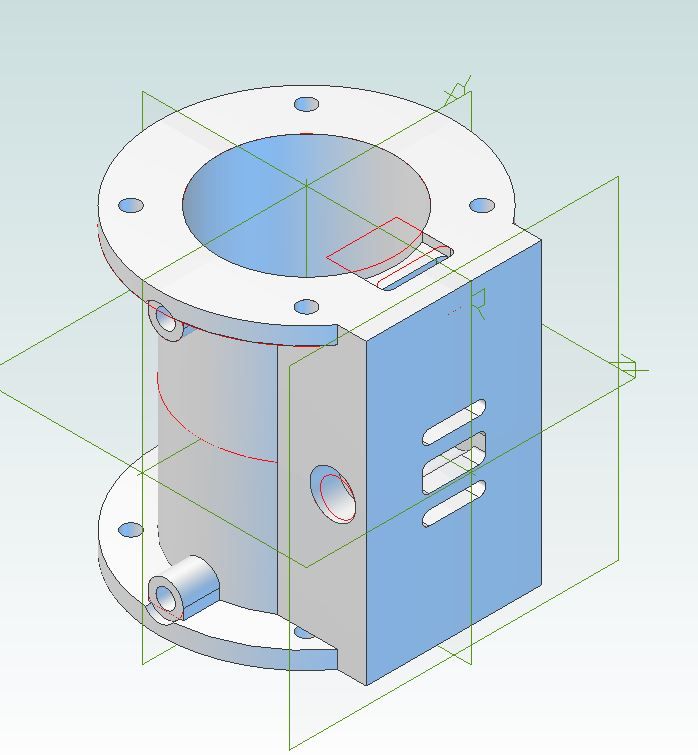

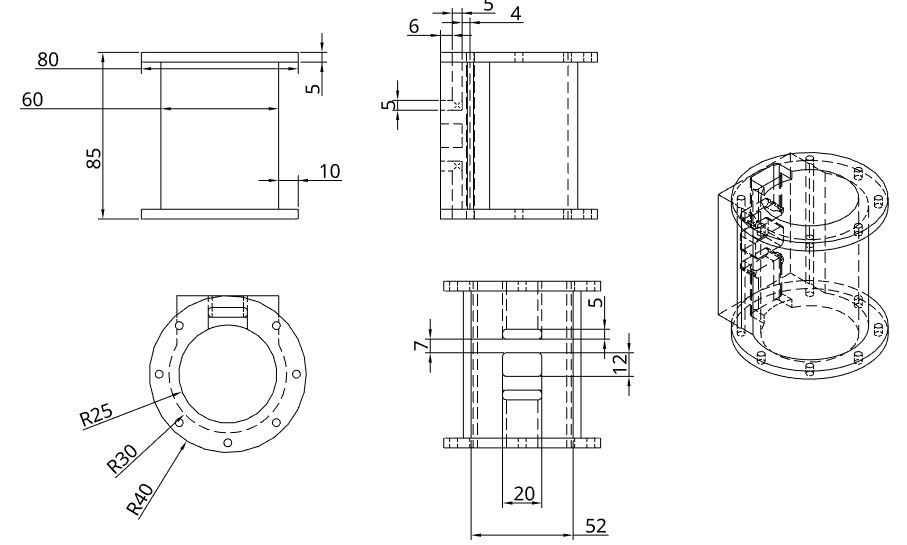

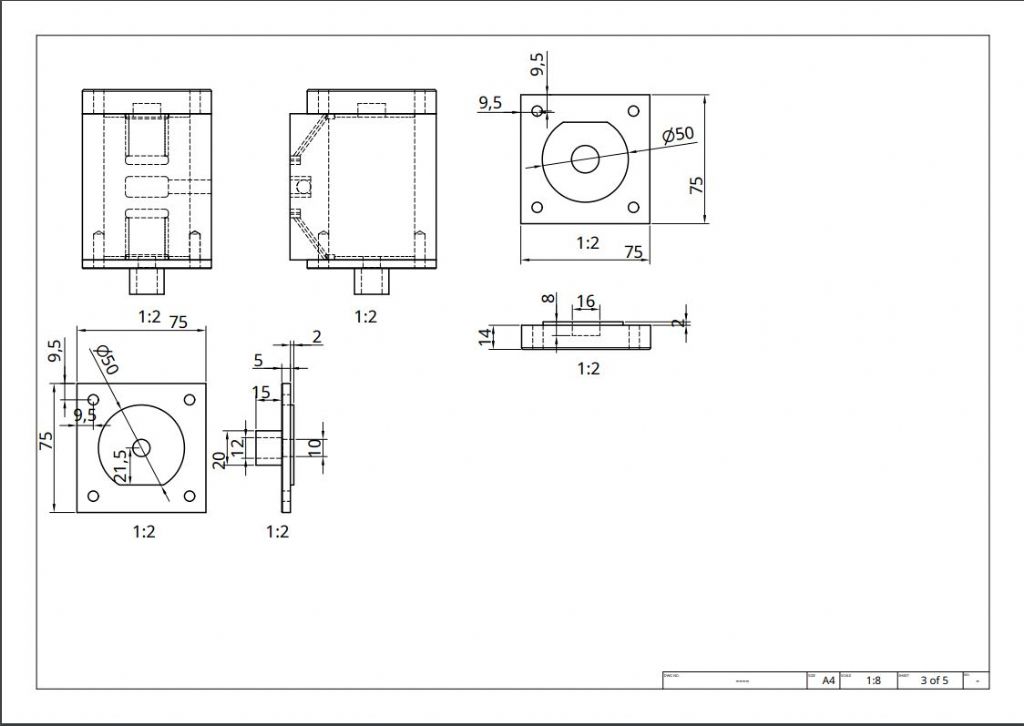

Cylinder and Caps

I'm thinking this would be one big bit of cast iron with the two end caps cut off and machined separately, though I may go for separate caps made of mild steel. This is the most complicated piece of work I think, though I've already has some advice from Richard Gribbins (Hope I spelt your name right, Richard) on how to do some hard parts.

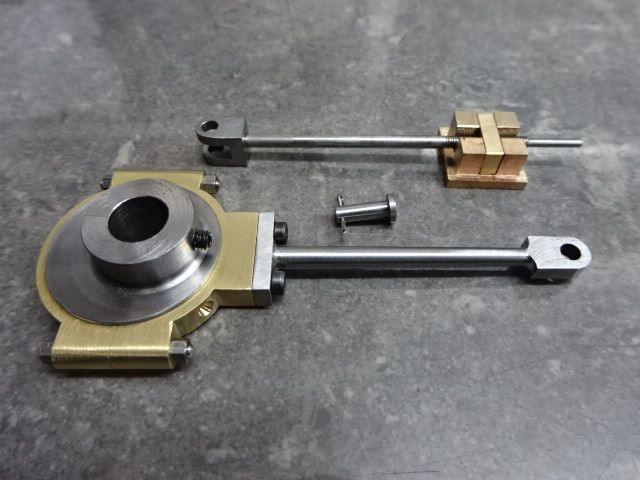

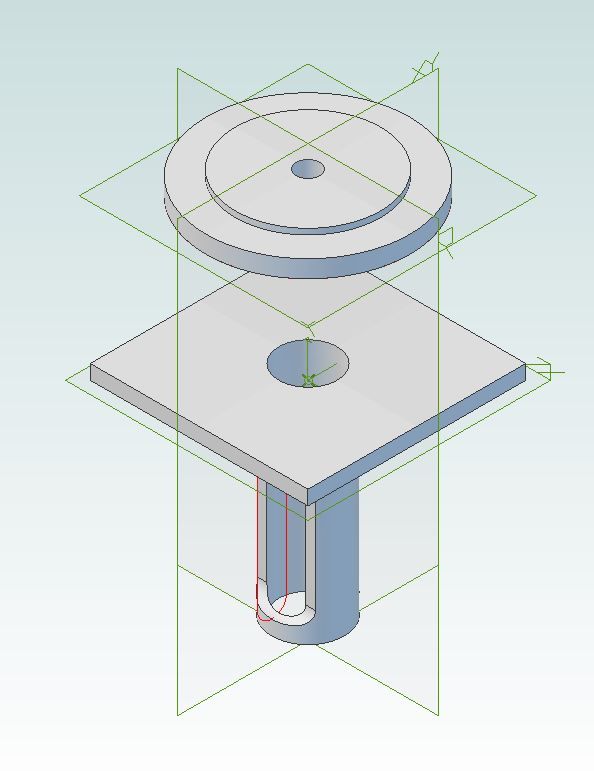

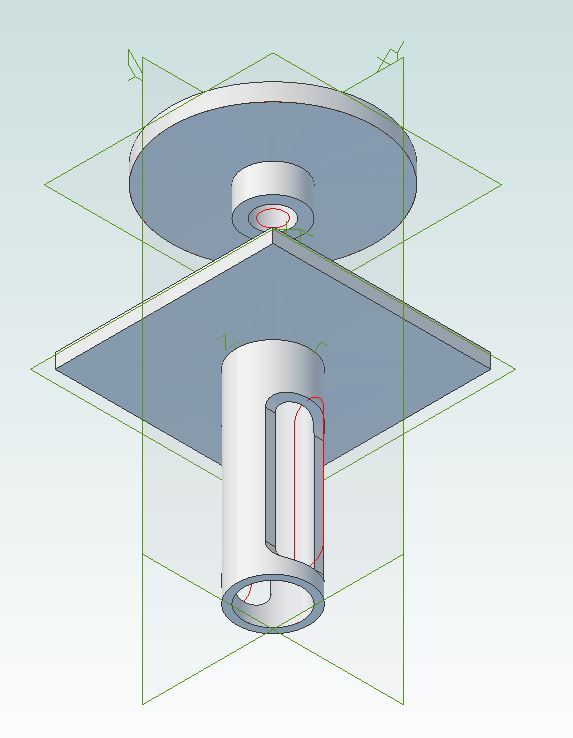

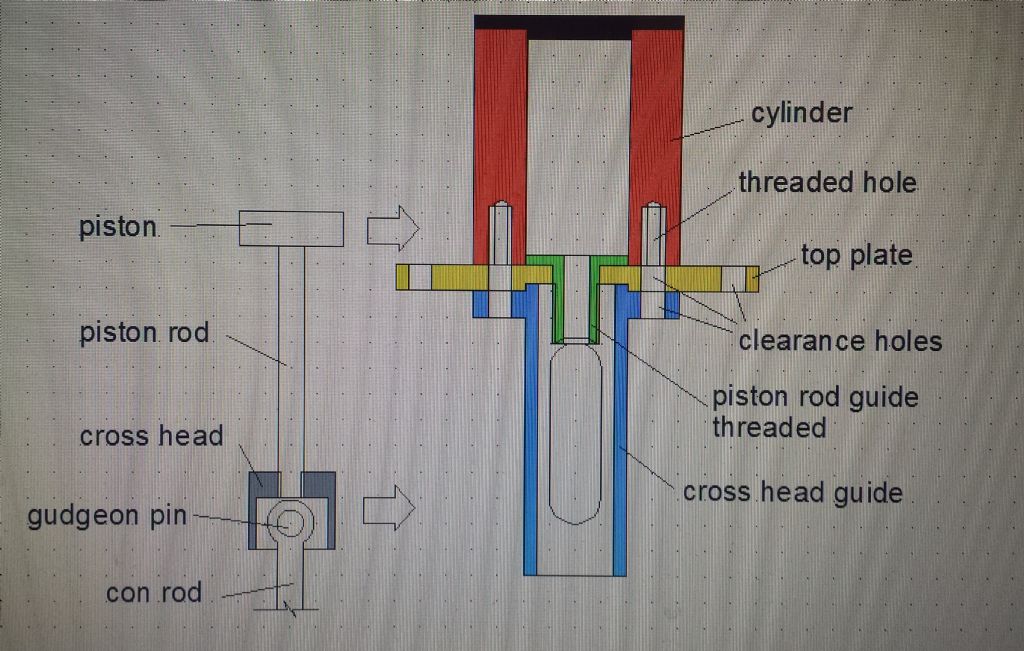

Piston to Big End

Not sure if I will make the big end bearings from cast iron or bronze, but the rest is steel. I'm also not sure if I should assemble the rods and joints from components and silver solder or try and machine out of whole steel. Most likely I will solder – the machining is probably too much.

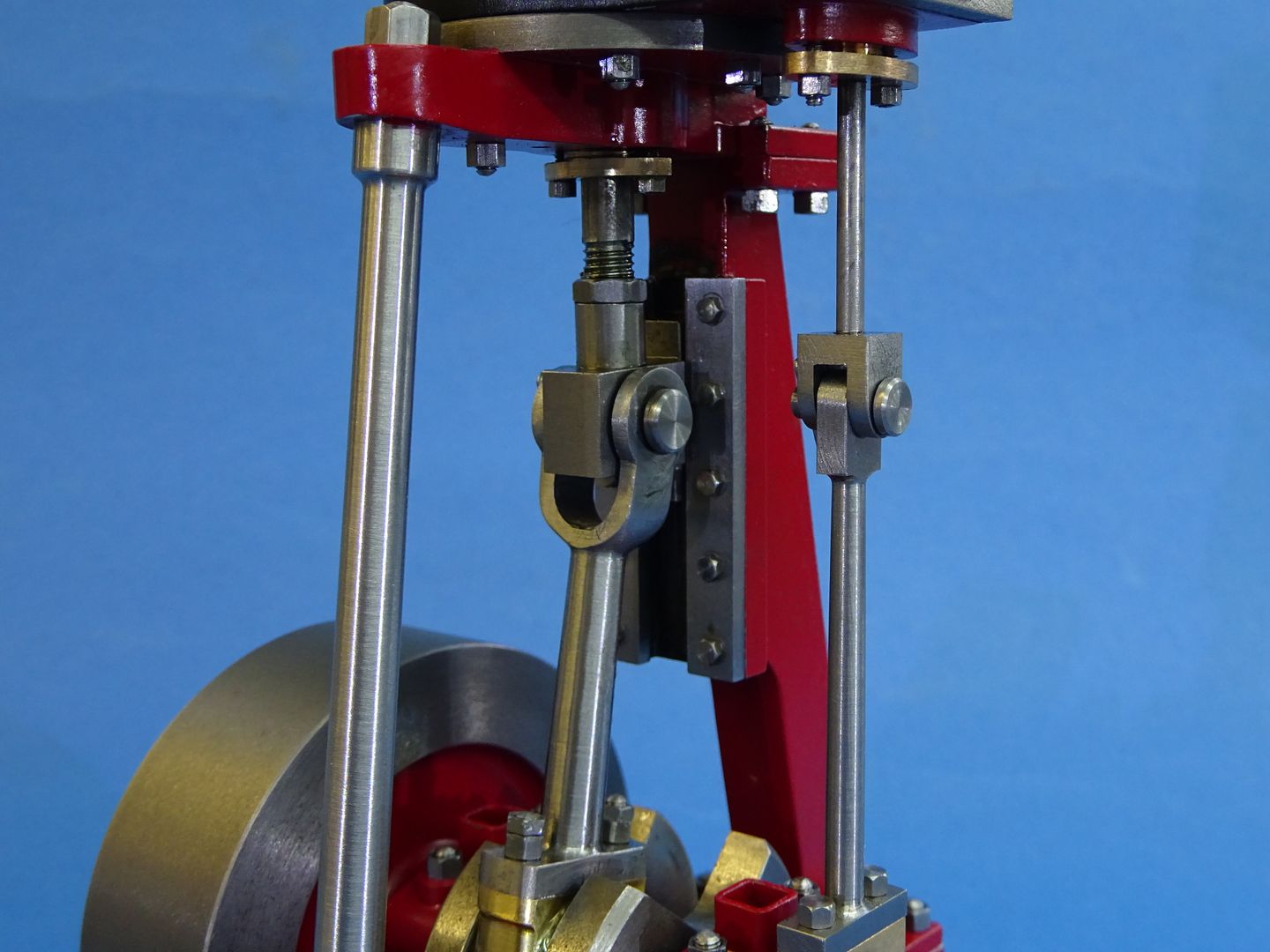

Frame

Connect the Crank to the cylinder. I'm thinking of using stainless for the support struts for the shinyness, even though it costs a bit more. Not quite sure how to finished the model off, paintwise. I did think of brass for the supports struts, but that's very pricey (and I'm not much of a one for polishing).

At this point I should be able put the whole thing together and make sure that it runs smoothly.

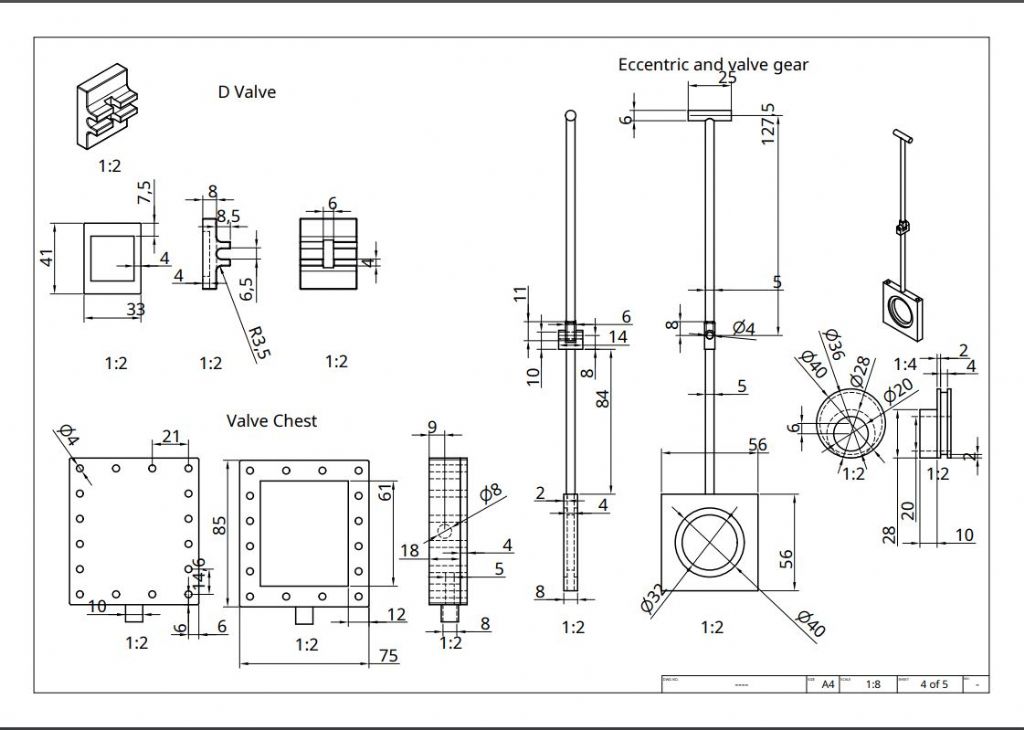

Valve Gear

Just one direction to start with. I'll put some reversing gear in if I get the easy stuff to work. Most of this mild steel, I think, though not sure of material for the eccentric bearing.

I expect to get the crank stuff done in the next few weeks and hopefully, the cylinder bits done by year end. It depends on the dreaded day job and, of course, how many times I have to throw bits away and start again.

Any corrections, warnings or other feedback is most welcome.

Iain

Andy_G.

Andy_G.

.

.