Thanks to everybody who has contributed to this thread. I have now gathered together the key data items for those who may be interested. I have also made the assumption that whilst I could build the canoe, any plant would need to be bought in from elsewhere.

Summary

a) The Full Steam Launch Option

Boiler – The Mike Robinson design monotube, oil fired by pot burner, 12kg.

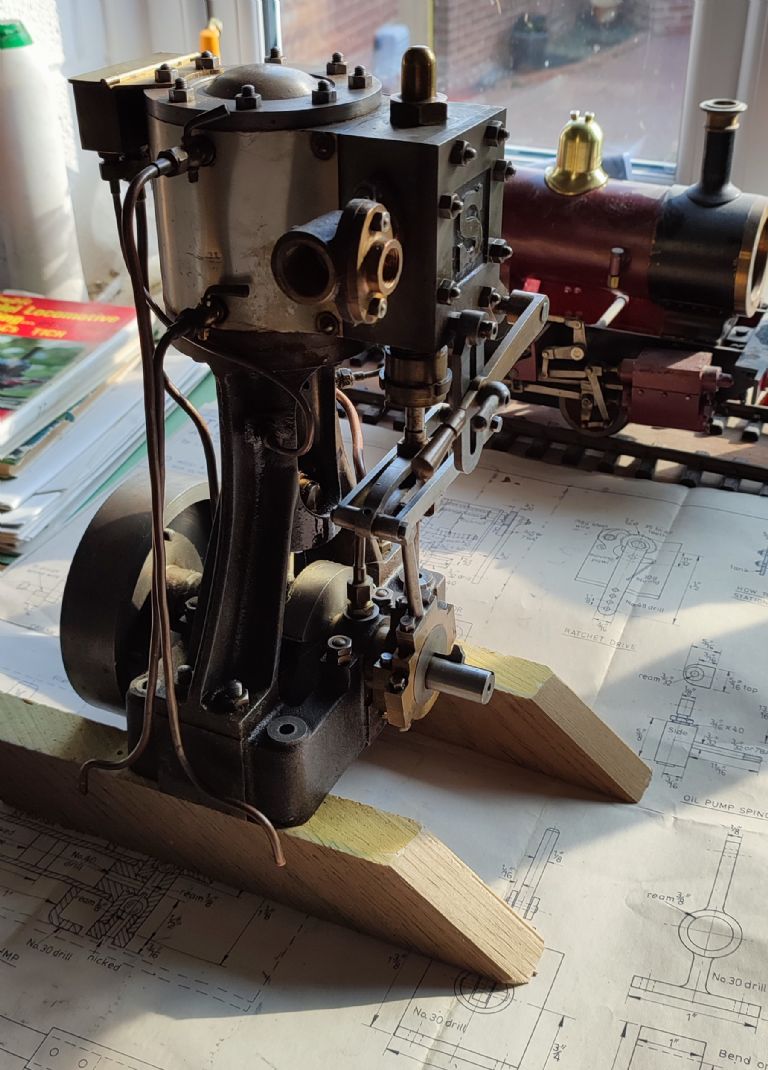

Engine – (i) ST Cygnet, 2.25” X 2”, 13.5 kg (Preferred option, Probability of acquisition – close to zero)

(ii) Custom built twin such as Ray Hasbrouch, < 10 kg (Second best option, Probability of acquisition – possible)

(iii) ST 5a, 2.25” X 2”, 13.5kg (Third best option, Probability of acquisition – very easy)

Propeller – Three blade 12” X 20” (May be reduced below 12” by using 4 blades and shifting the DAR from 0.4 to 0.6 – Weight = 1.7kg)

NB Drive train not yet specified or weighed

b) The Electric Poser Option

Boiler – No thoughts yet.

Engine – ST No 1, 2” X 2”, 10kg?, (Probability of acquisition – possible)

Outboard – Minn Kota Endura C2 30 12v, 6.8 kg

Leisure Battery – (Say) YBX Active Specialist & Garden Battery 12V 30Ah 330A 7.8kg

Wiring and controls extra.

c) The Paddle Steamer Option

Boiler – The Mike Robinson design monotube, oil fired by pot burner, 12kg.

Engine – Scaled up Westbury Paddle Engine. Weight unknown. (Probability of acquisition – zero)

To conclude I rather feel that the 'Full Steam Launch' option would be the best as it ticks all the boxes in terms of live steam and posing. The electric version but skipping the poser bit would actually be the cheapest route to a powered canoe although a little more than 30 Ah might be advisable (if my sums are correct).

Regards

Pete

Peter Cuthbert 1.