Back again, lots of questions at the mo.

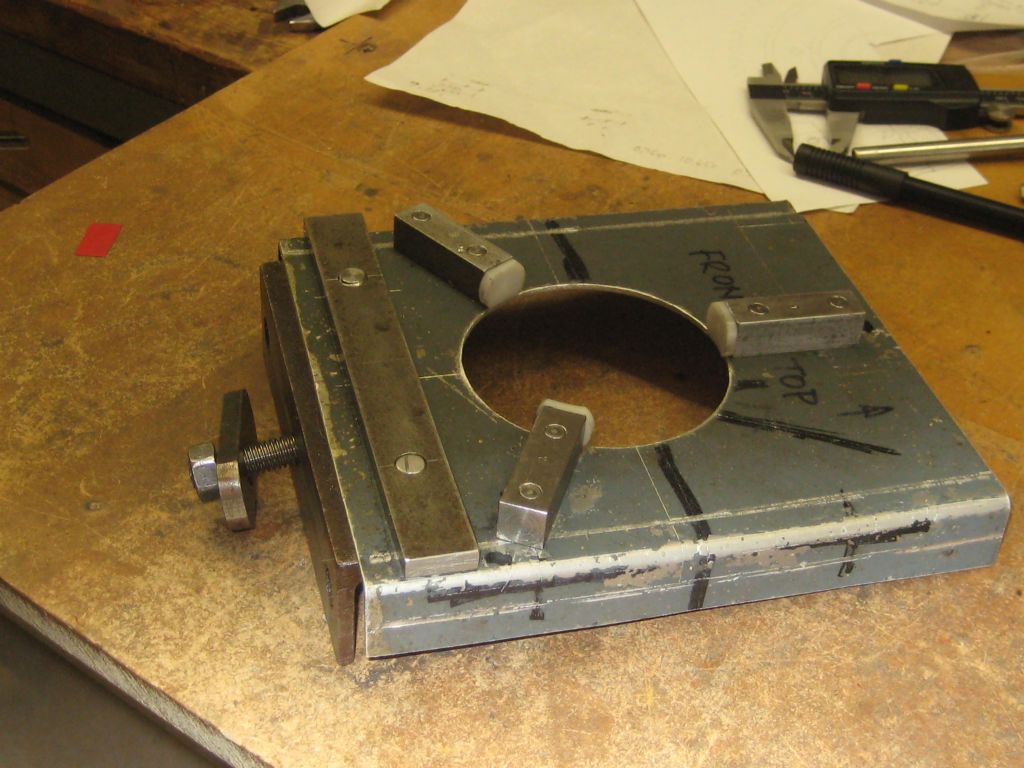

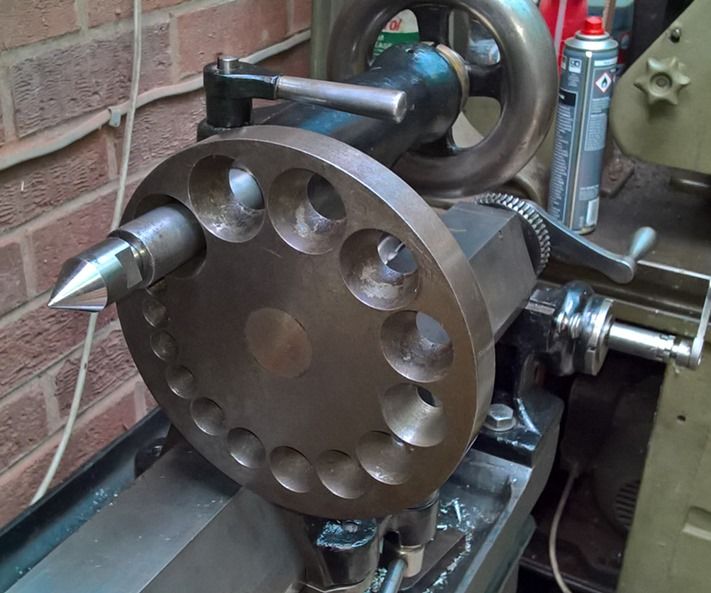

I need a larger mini lathe steady rest than is available commercially.

This has been on the 'to do' list for a while. Time to do.

As i'm going to have to make one may as well make it with circa 4.5" capacity to cover all bases.

I see Hemmingway do a kit for a 5" myford rest that could probably be adapted.

& There are numerous exam[les of DIY rests on the net.

However, i'm thinking K.I.S.S. ,I't doesn't need to be a work of art,It just needs to do the job.

I could spend weeks/ months making the mother of all mini lathe steady rests, but why?

I like the idea of brass fingers, but brass tipped bolts is simpler.

I like the idea of a cast iron body , but that's slower work than Aluminium.

My questions are namely thus~

Are steady rests subjected to any great load (in a home shop environment)

&

Would any vibration damping offered by cast iron be worthwhile/ noticeable on a hobby machine?

Thanks.

ega.