Crikey, these balls are only 5/32" diameter – not sure I can put a centre in one of those… but jason was right enough my form tooll needed sharpening and a bit more care in setting the centre height. Too much overhang too.

It's an horrendous £2.87 for 10 to buy ready made ones, so I did much thinking last night and in the bath this morning I came up with a cunning scheme…

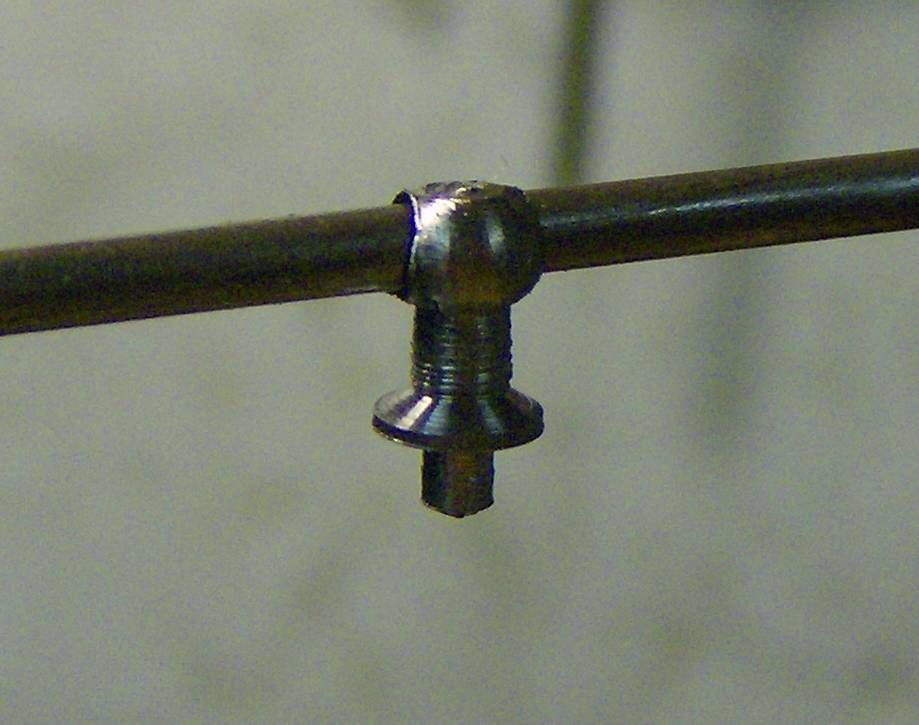

I made a jig for centre-drilling the brass rod (which was a force fit in the jig to ensure it didn't move), and drilled both ends of a small pile of short bits of rod (as stew suggests). I then turned the balls using the form tool (sharp and set properly), filing the pip at the end fair with a diamond file. Next I worked through them all with a 1/16" parting tool to complete the necks and create a suitable stub for the thread. I cut them off with side cutters, as when I parted the first one off it disappeared into the distance.

Still a few more scrappers, from over-enthusiatic feed but I ended up with these:

Which I'm not ashamed of at all!

Neil

Edited By Stub Mandrel on 07/04/2012 20:54:30

Jim Nolan.