Posted by Michael Gilligan on 17/05/2020 14:46:16:

Posted by Ron Laden on 17/05/2020 14:34:10:

[…]

I was lazy this morning, I was going to file the teeth but did it all on the lathe and mill in the end.

.

A brief description of how you went about that would probably be useful to many, Ron

Excellent result, Sir !!

MichaelG.

Thanks Michael,

I started with a piece of 10mm silver steel bar and turned the 6mm shank and 8mm body as one piece, I then drilled a 4mm hole (M4 clearance) 10mm deep into the body to take the 4mm spigot later. I should say before someone jumps on me I dont use recommended clearance sizes, for me I think the are too big so M4 I use 4.0mm, M6 – 6.00mm, M8 – 8.0mm etc.

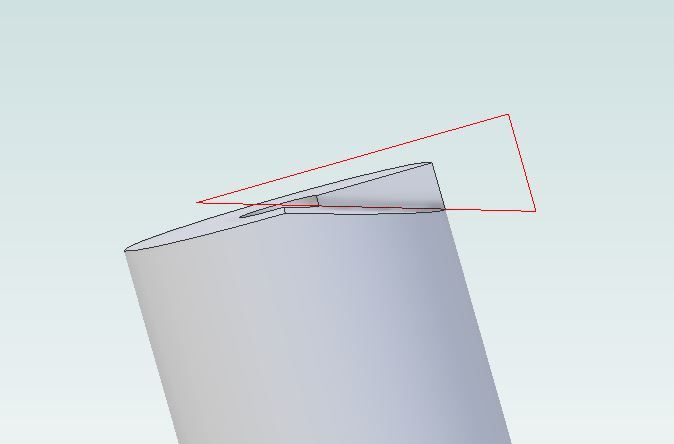

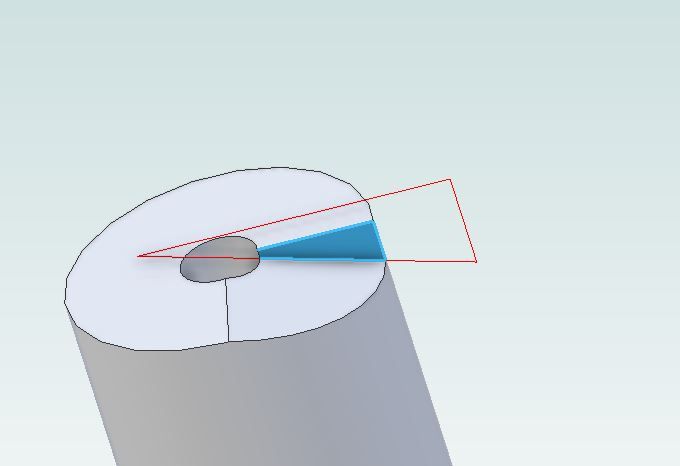

Milling the teeth I just picked up on one of Jasons pictures where he showed the tool set up in a Stevensons square collet block at an angle on the mill. I dont have a Stevensons block (yet) so had to come up with something else. I drilled a 6mm hole to accept the shank through a piece of alu round bar and fitted a grub screw to lock the shank. I then squared of the sides of the bar making sure the four faces were 90 degrees to one another (picture below).

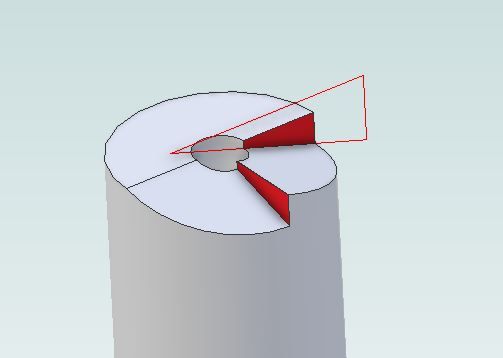

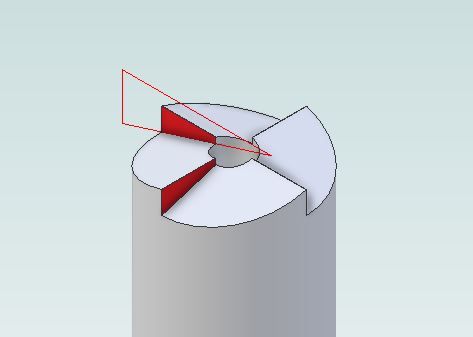

With the tool locked into the bar/block and the block mounted in the vice I set up the angle for cutting the teeth. The angle was created simply by positioning the side of block against a piece of flat bar on which I had milled an angle on the end, nothing technical I havnt measured the angle I just went with what I thought looked right for the teeth. I then positioned the vice in Y so the the edge of the cutting tool was at the centre of the tool body, touched off the tool to the top of the body and then took 4 x 0.5mm cuts in X, 2.00mm total which again looked about right. It was then just a case of turning the block through 90 degrees and repeating the same for the othe 3 faces. I then stood the block vertical and "just" skimmed the top of the four teeth to make sure non were sitting proud. Then ten minutes spent with the diamond file I created a shallow rake angle on each tooth.

Then finished with the hardening and fitted the spigot with 638 retainer.

Sorry for the war and peace explanation but its the best way I could explain it.

Ron

Anonymous.