Posted by Michael Gilligan on 15/05/2020 23:13:07:

Posted by Dr_GMJN on 15/05/2020 22:34:08:

[…]

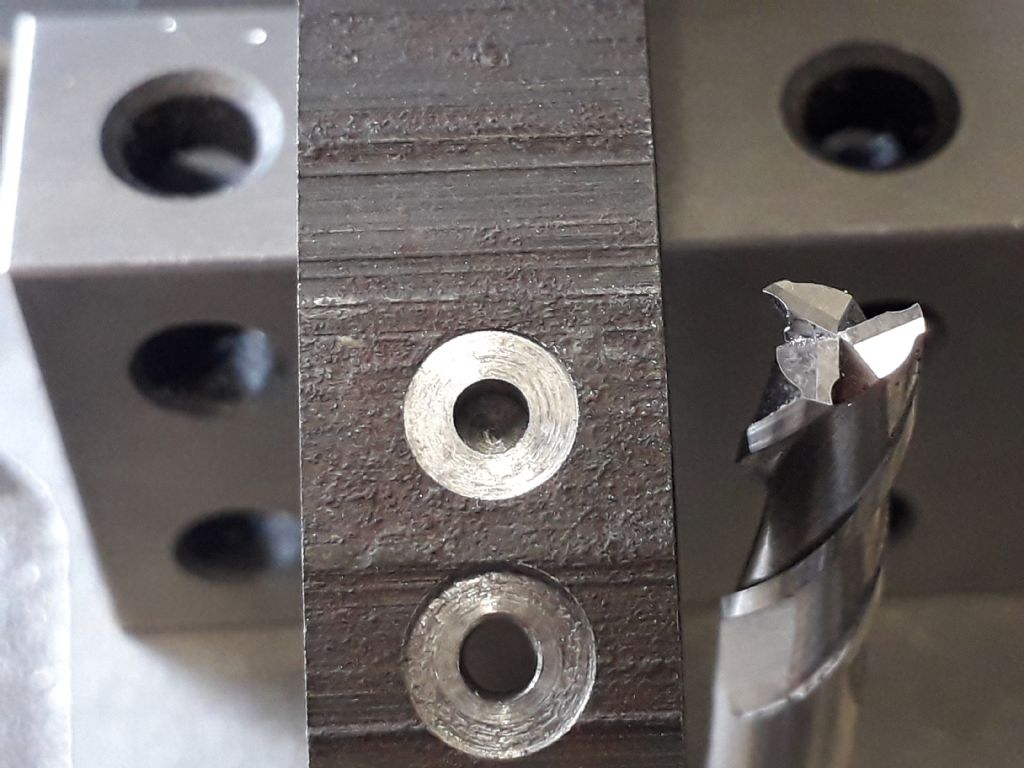

I did lock the axes before machining.

I did a subsequent test on some plain steel, exchanging the drill bits and slot drill, again with the axes locked, and it still gave a non-concentric circle. Perhaps the existing holes are dragging the cutter off centre? I should have tried cutting the spot face first.

.

If I read that correctly … it’s worrying

Assuming that the job is properly secured and the X & Y axes are locked: that would imply that the head is moving

Perhaps your concern about the column is worth investigating further.

MichaelG.

I agree with Michael – cause for concern. It seems something is moving.

I'd reach for a DTI next. With the machine switched off, I'd methodically confirm that everything really is locked down solid.

Start by holding a lever DTI on the quill and have it register a couple of mm on the vice before pushing the quill and then table hard with a thumb. Move DTI as necessary to repeat test in both X and Y directions. For example, with the lever in a table slot, can the locked table be moved in X, and by how much? Repeat test in both X,Y on the vice, and then to the vice's moveable jaw. Test at several different table, head, and quill settings.

When applying the DTI test to a small milling machine minor some movement should be detected : metal bends! But not very much. Worth taking measurements and reporting back I think.

DrGMJN has encountered a number of different problems with his new mill. Could be a combination of Learner Driver syndrome, difficult materials, and a few unlucky tool purchases, but maybe there are problems with the machine. Worth checking I suggest.

My first suspect is maladjusted gibs are allowing the table and/or head and/or quill to move whilst cutting. With incorrectly set gibs the amount of movement is likely to vary depending on table/head position. (Tight in some places, slack in others. ) Loose gibs cause vibration, poor finish, and inaccurate cutting, which seems to match the symptoms.

How bad the ill-effects are depends on the cutting operation, for example drilling doesn't rely much on the gibs because spinning drills stabilise on the spindle axis and encounter few sideways forces. On the other hand tight gibs are vital to most milling operations because the sideways forces are massive and change direction depending on the cut. Gibs problems may explain why the Doc is getting mixed results. If not the gibs, then maybe something else is wrong with the machine. The hunt is on! Avoid assumptions; the goal is to eliminate guesses until the truth emerges.

A word of warning! When testing a machine with a DTI, it's easy to confuse actual faults with poor measurement technique. Fine measurements are extraordinarily sensitive to set-up errors and instrument shortcomings. One can end up lost in a maze of red-herrings, so don't jump to conclusions. My inexpensive DTI is accurate enough but it's slightly sticky at some points; when using it for this sort of work I have to make sure it's working in it's comfort zone! Not really worth me buying a better DTI, but being able to completely trust the instrument does make this sort of measurement task quicker and safer.

Dave

Anonymous.

Double post, again….

Double post, again….