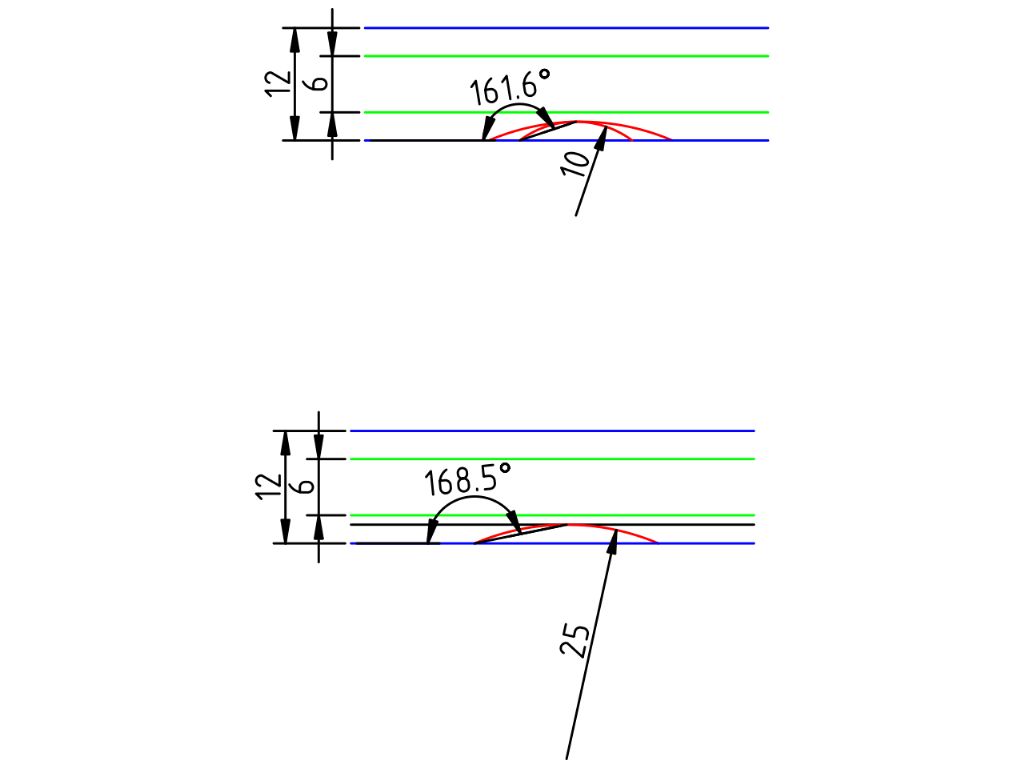

My thinking was that the curved section of the pad forms a taper that increses along it's length and is at it's minimum at the pad bolts inner edge. The taper is actually the Tangent to the clamped shaft at the point of interest and so is only defined by the gap and the radius of the clamped bar. (I see now where my maths went wrong I used the Diameter not the radius, note to self don't do maths at bedtime).

Once the angle has been found one must just ensure that it is greater than the critical angle for the transition between self holding and self locking, given in most books as 7 degrees.

You are more than likely correct in saying there is more to taper locking as far as analysis is concerned but that is 'built in' when the transition angle of 7 degrees is taken from the literature.

The diameter of the two half nuts or pads is irrelevant as this only determines where the taper 'leaves off' at the outer end of the pad and, as this must be a greater taper angle, is of no concern.

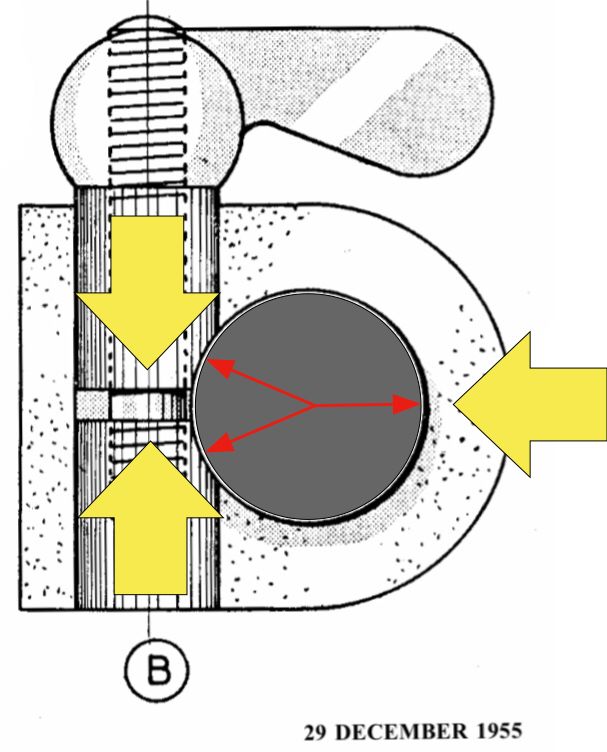

Duncans G=D/8 certainly gets you where you want to be and if there is any tendency to fail to unlock, facing a fraction off the inner ends of the pads will easily correct it.

regards Martin

Edited By Martin Kyte on 25/06/2021 10:31:21

Edited By Martin Kyte on 25/06/2021 10:32:34

ChrisLH.