Hi Jon ,

the first thing I’d do is test the board without the motor

don’t forget all the board is live

first with a 100W (or 60W) gls bulb in series with the live supply

this acts as a current limiter if D1 (FR307) , C1 (4n7F 2000V ) or the bridge rectifier( KBPC1010 ) are short circuit – eco compact flourescent bulbs don’t work for this test

and a 15W bulb in place of the motor.

if the board is working you should be able to control the brightness of

the 15W bulb / dummy load

note the 15W bulb may just glow at the minimum speed setting

next if that worked connect the mains as normal and test with the 100W bulb

as the load.

passing this test points to the motor (or too small a fuse)

if you have no control and the 15W bulb is at full brightness

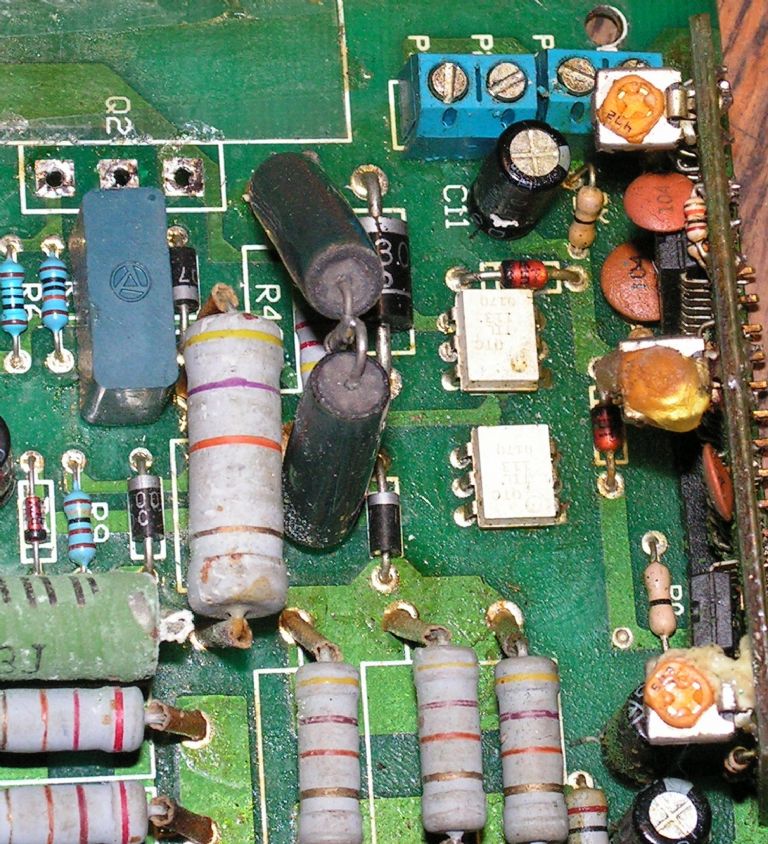

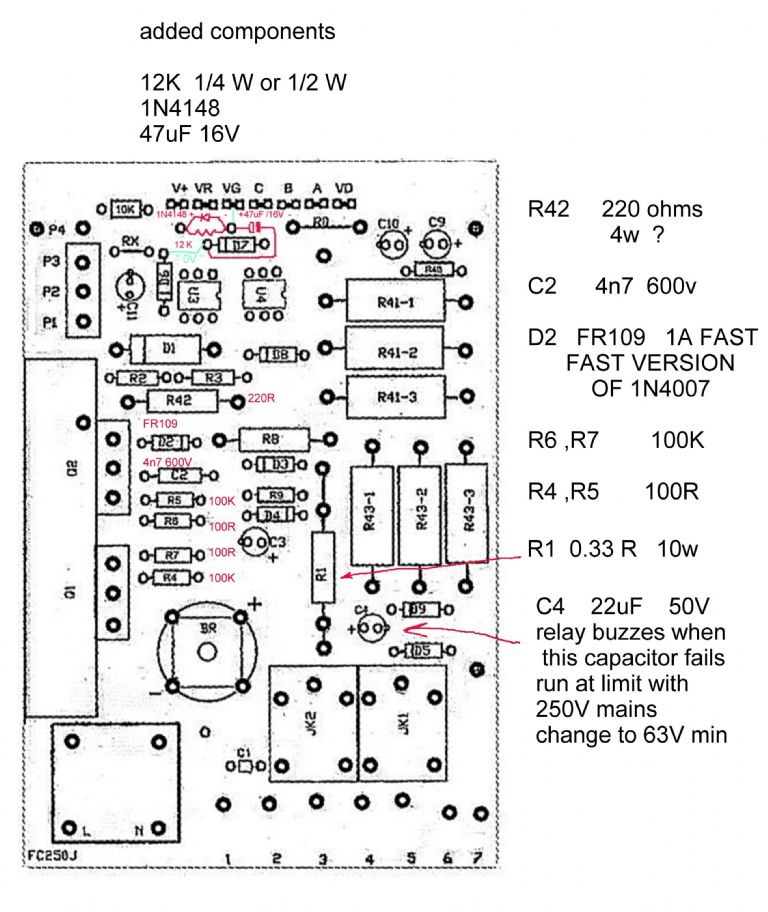

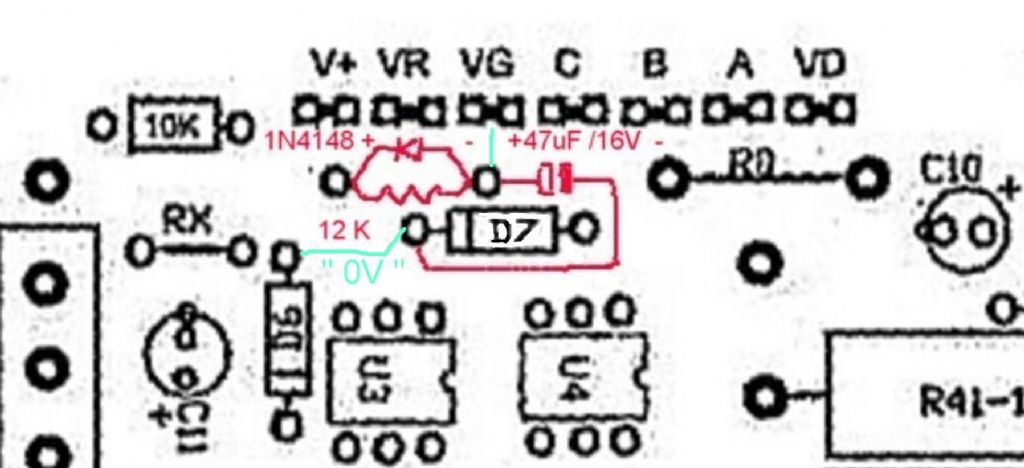

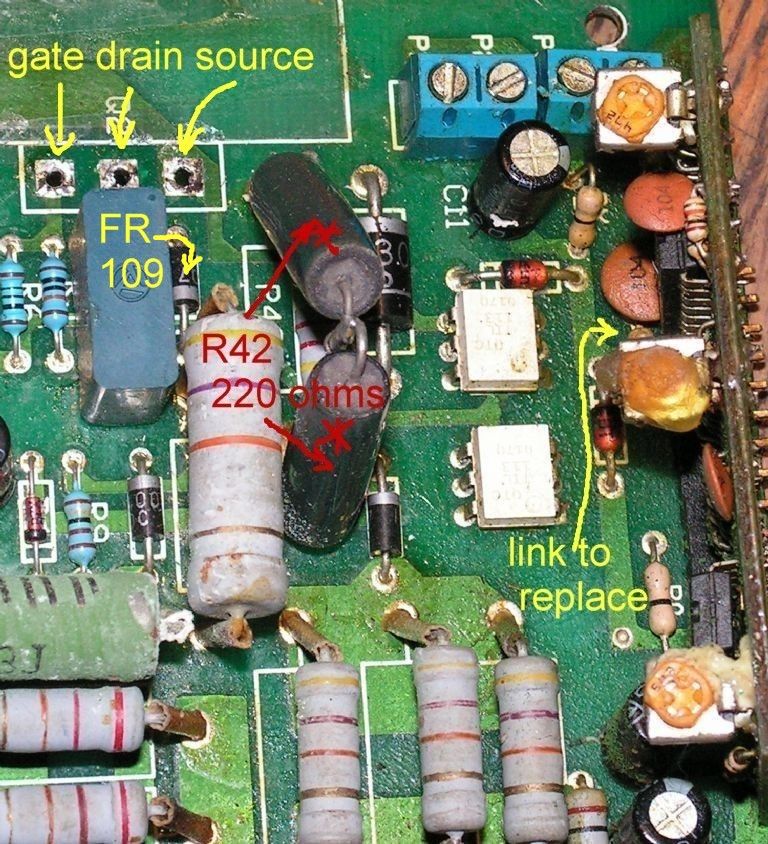

check C2 ( 4n7 600V) , D2 ( FR109) and the FET’s are not short circuit

for testing with the bulbs you can first remove C2 , ( removes C2,D2 and R42

from the circuit)

next lifting one end of R9 (1k8) will remove any voltage switching on the fets if

the opto isolators or the PWM control is faulty.

may save removing the FET’s if they are OK

Arc euro trade are selling the new SMT boards for £60 if you need a quick fix

once the motor is tested

John

jacek nowak.

. I have older FC250/230V with FETs on the left. My broblem: first it was not completely stop the engine. The engine is still spinning slowly. I set the trimmers to the daughter board and all was ok. But only for a two days. Then the same problem. Setting trimmer has had no effect. There’s so much that it now has no response to rotation of the potentiometer knob. I allready replace the both FET transistors, Til 113 and LM324N. But nothing. It seems to me that a daughter board is not working as it should. Voltage on the optocouplers does not change when I turn potentiometer. Would help me if I knew what the approximate voltage should be on U1c pin 8,9 and U2a pin 2,1 at potentiometr set min. and max position. Or any other ideas how to revive the regulator? Can anybody help me? Than you very much for any reply.

. I have older FC250/230V with FETs on the left. My broblem: first it was not completely stop the engine. The engine is still spinning slowly. I set the trimmers to the daughter board and all was ok. But only for a two days. Then the same problem. Setting trimmer has had no effect. There’s so much that it now has no response to rotation of the potentiometer knob. I allready replace the both FET transistors, Til 113 and LM324N. But nothing. It seems to me that a daughter board is not working as it should. Voltage on the optocouplers does not change when I turn potentiometer. Would help me if I knew what the approximate voltage should be on U1c pin 8,9 and U2a pin 2,1 at potentiometr set min. and max position. Or any other ideas how to revive the regulator? Can anybody help me? Than you very much for any reply. .

.